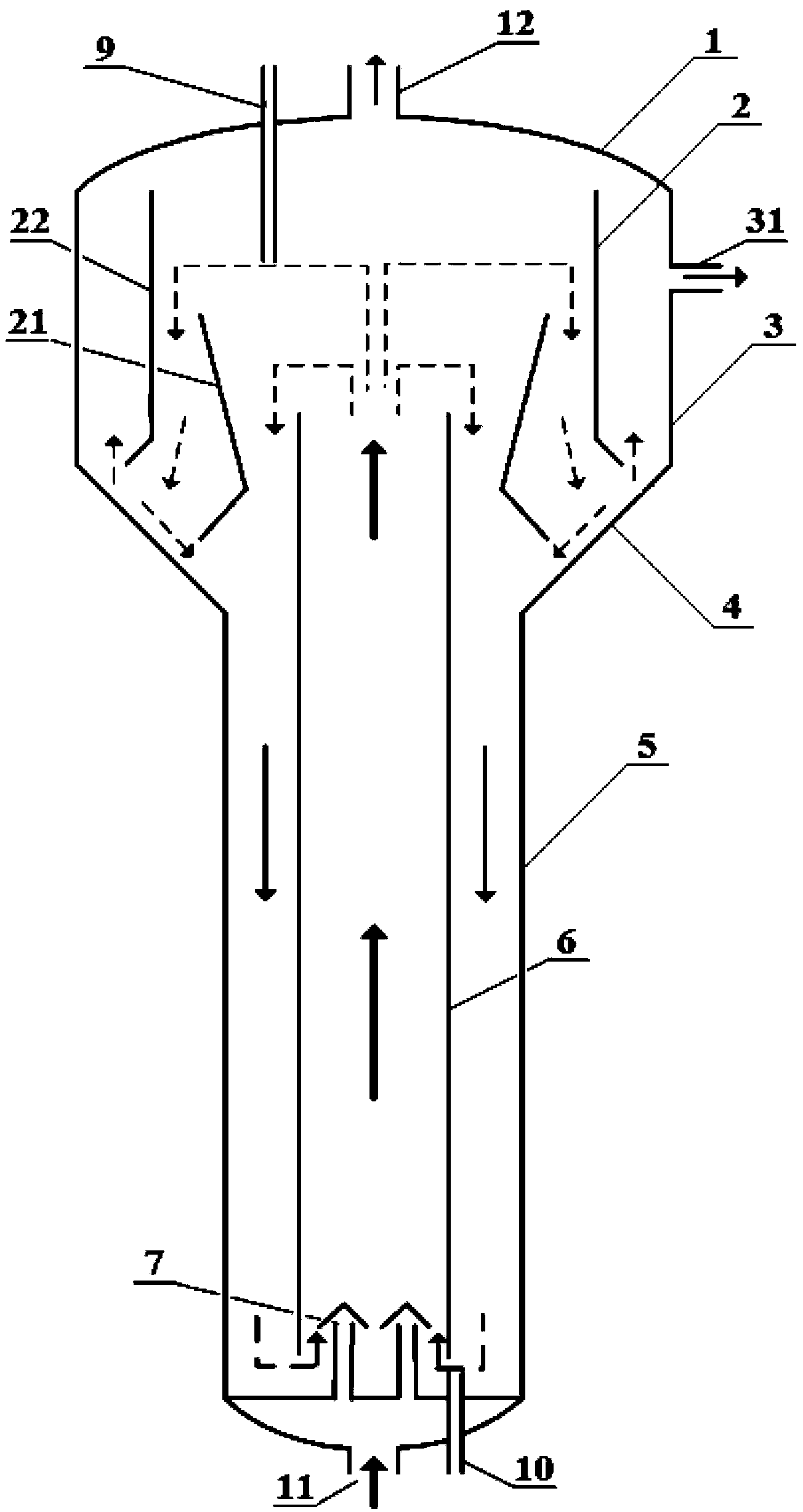

Fluidized bed reactor

A fluidized bed reactor and gas-liquid distributor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of lowering product quality, equipment shutdown, and low operating flexibility, reducing thermal cracking reactions, improving The effect of utilizing efficiency and avoiding coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

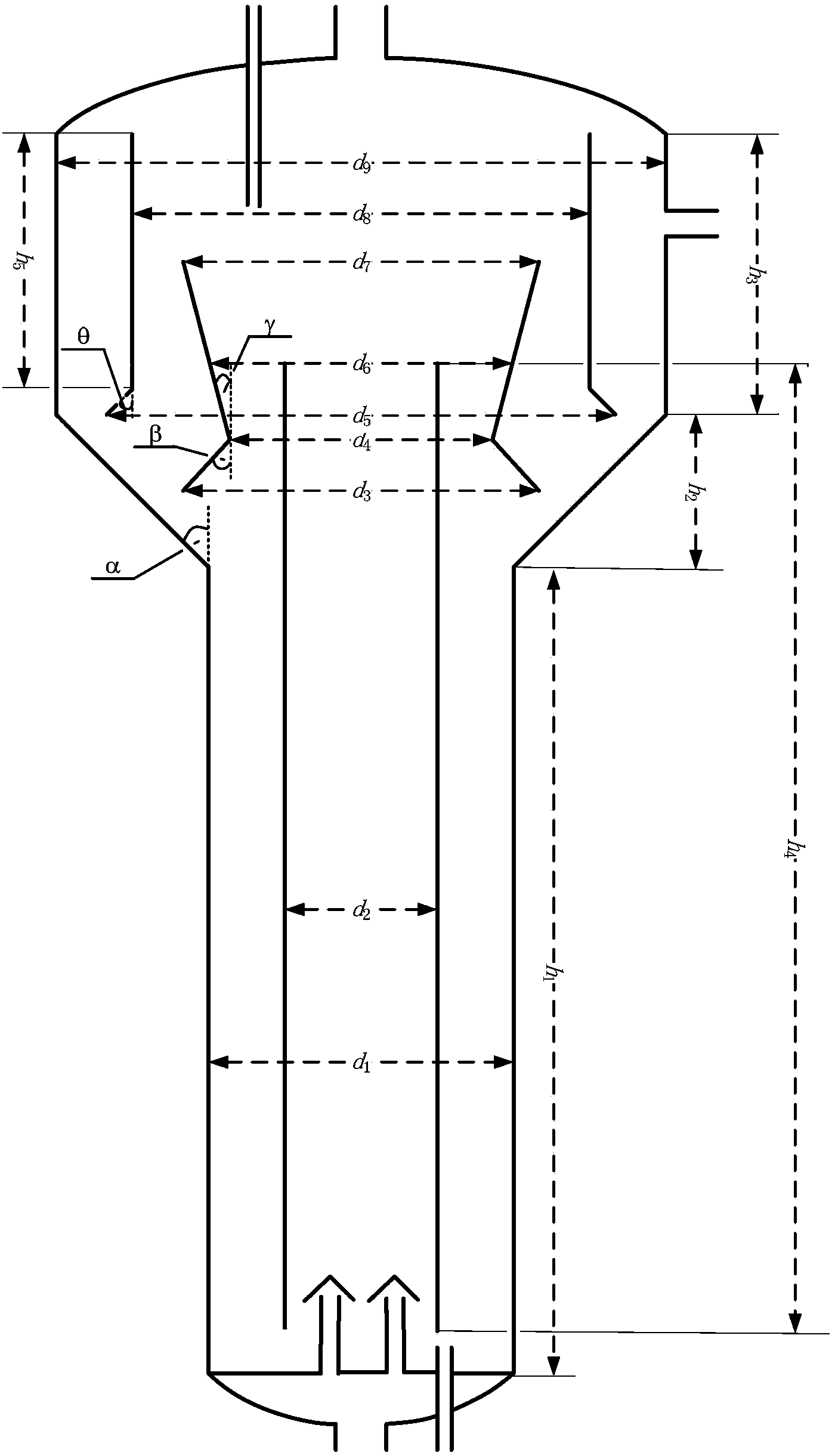

[0067] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 1 below.

[0068] The solid catalyst is a spherical catalyst with a particle size of 0.2-0.3 mm. The catalyst loading is 55% of the effective volume of the reactor. The liquid phase uses straight-run kerosene, and the volume space velocity is 0.25-3h -1 . Nitrogen is used in the gas phase, and the gas-oil volume ratio is 20-150.

[0069] The detection of the liquid discharged through the liquid discharge port 31 revealed that the carried-over amount of the solid catalyst was 2.1 μg / g, which shows that the carried-over amount of the catalyst is extremely low.

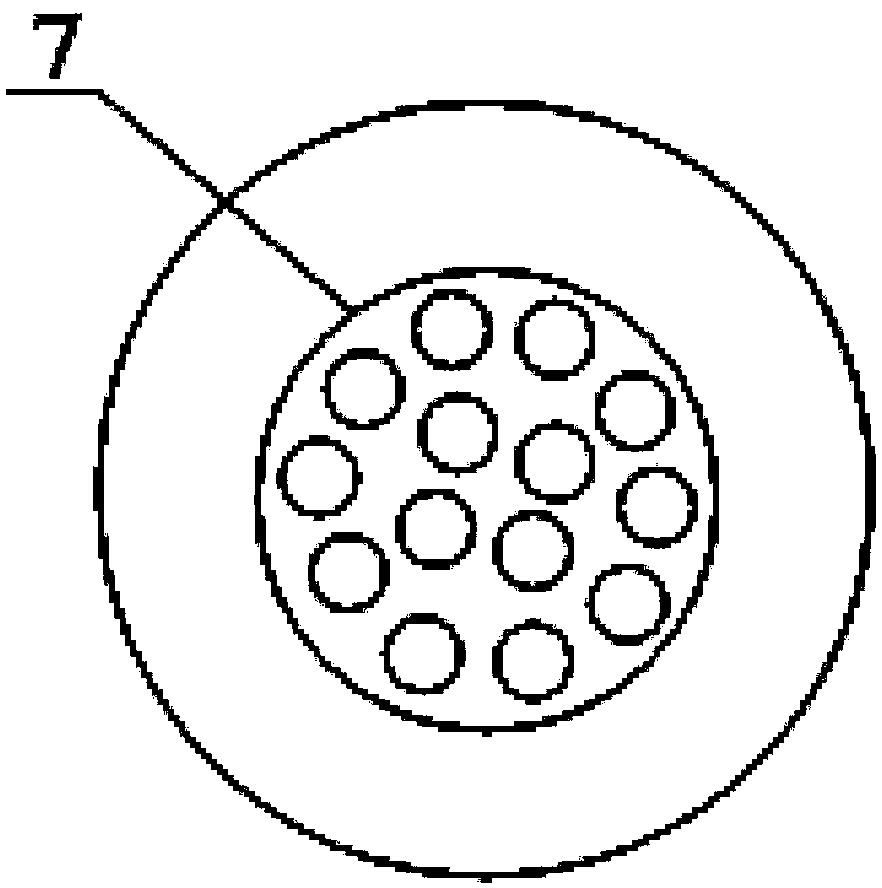

[0070] Moreover, it is found through observation that there is also sufficient circulating gas in the downcomer (that is, the annular tube area formed by the inner tube 6 and the straight tube section 5), and the fluidization state of the solid catalyst is good.

[0071] Table 1

[0072] code name

Embodiment 2

[0074] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 2 below.

[0075] The solid catalyst is a spherical catalyst with a particle size of 0.5-0.6 mm. The catalyst loading is 45% of the effective volume of the reactor. The liquid phase uses straight-run kerosene, and the volume space velocity is 0.25-3h -1 . Nitrogen is used in the gas phase, and the gas-oil volume ratio is 20-150.

[0076] The detection of the liquid discharged through the liquid discharge port 31 revealed that the carried-over amount of the solid catalyst was 1.6 μg / g, which shows that the carried-over amount of the catalyst is extremely low.

[0077] Moreover, it is found through observation that there is also sufficient circulating gas in the downcomer (that is, the annular tube area formed by the inner tube 6 and the straight tube section 5), and the fluidization state of the solid catalyst is good.

[0078] Table 2

[0079] code name

[0080] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com