Method and device for extracting and separating praseodymium and neodymium

An extraction and organic extraction agent technology, applied in the field of solvent extraction and separation of rare earth elements, can solve the problem of low single-stage extraction rate of praseodymium and neodymium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

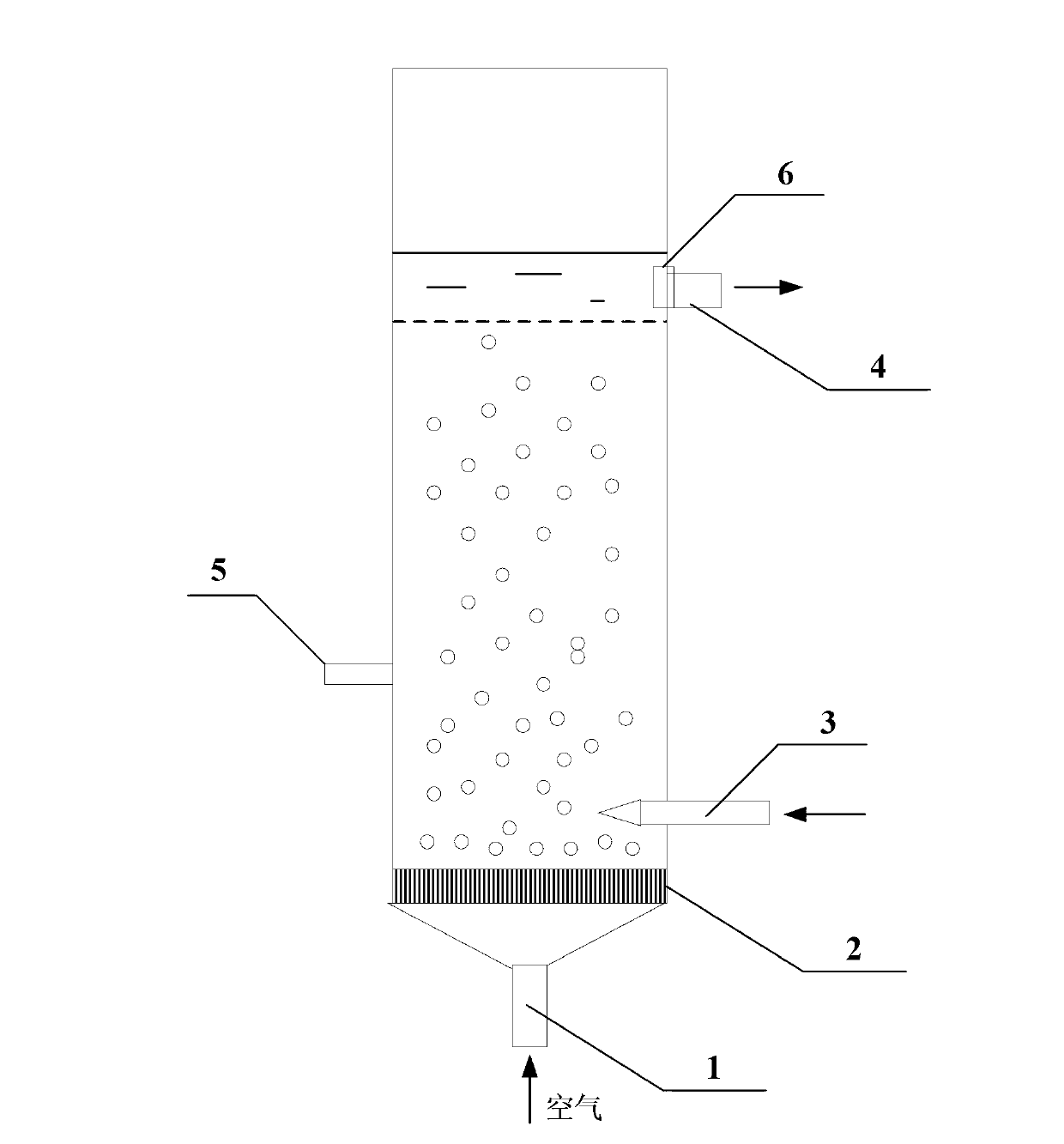

Image

Examples

Embodiment 1

[0044] Dissolve the oxides of praseodymium and neodymium with 100mL of hydrochloric acid aqueous solution with a concentration of 0.1mol / L, and prepare a mixed solution containing praseodymium and neodymium ions (the initial concentration of praseodymium ions is 50mg / L, and the initial concentration of neodymium ions is 80mg / L) . At room temperature, add DTPA, the ratio of the added molar amount to the molar amount of praseodymium ions in the initial aqueous solution is 1:1, and adjust the pH value of the mixed solution to 5. Then air bubbles are blown into the mixed solution, and 80% by volume of di(2,4,4-trimethylpentyl)phosphinic acid in kerosene is slowly added at a rate of 0.5mL / min Solution 5ml. After all the 5ml of organic solvent was added, the organic phase at the top of the container was collected, and the neodymium in it was recovered by stripping. Ammonium oxalate was added to the stripping solution to precipitate, and the precipitate was washed, filtered, and bur...

Embodiment 2

[0046] Dissolve the oxides of praseodymium and neodymium with 100mL of hydrochloric acid aqueous solution with a concentration of 0.1mol / L, and prepare a mixed solution containing praseodymium and neodymium ions (the initial concentration of praseodymium ions is 50mg / L, and the initial concentration of neodymium ions is 20mg / L) . At room temperature, DOTA was added, and the ratio of the molar amount added to the molar amount of neodymium ions in the initial aqueous solution was 5:1, and the pH value of the mixed solution was adjusted to 4. Then add 20 grams of ammonium sulfate to this mixed solution, blow in air bubbles, and slowly add the weight of modified 2-ethylhexyl phosphate mono-2-ethylhexyl ester organic functional group at a speed of 5mL / min under the state of blowing air. 50ml of PEG aqueous solution (pH=4) with an average molecular weight of 2000, of which PEG2000 content is 10g. After all the 50ml PEG2000 aqueous solution has been added, collect the polymer phase ...

Embodiment 3

[0048] Dissolve the oxides of praseodymium and neodymium with 300mL of hydrochloric acid aqueous solution with a concentration of 0.1mol / L, and prepare a mixed solution containing praseodymium and neodymium ions (the initial concentration of praseodymium ions is 100mg / L, and the initial concentration of neodymium ions is 85mg / L) . At room temperature, DOTA was added, and the ratio of the added molar amount to the molar amount of neodymium ions in the initial aqueous solution was 2:1, and the pH value of the mixed solution was adjusted to 4. Then add 60 grams of sodium sulfate in this mixed solution, blow into air bubbles, under the state of blowing air, slowly add the weight-average molecular weight that has modified two (2-ethylhexyl) phosphate organic functional groups at a speed of 1mL / min. 2500 EOPO20ml. When all 20ml of EOPO was added, the polymer phase at the top of the container was collected, and the praseodymium contained therein was recovered by stripping. Ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com