Extraction separation method for heavy rare earth elements

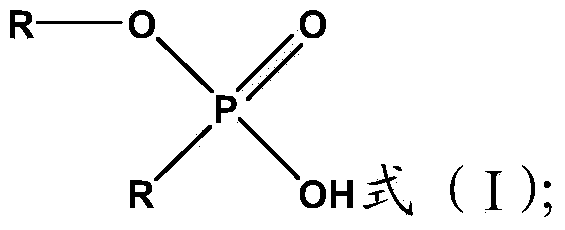

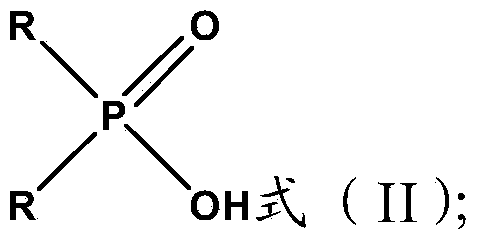

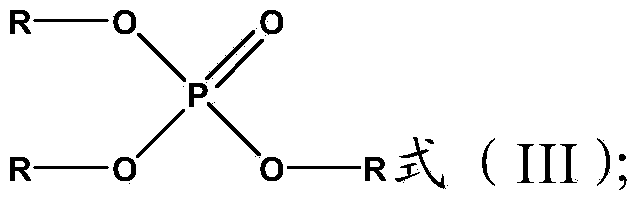

A separation method and technology of rare earth elements, applied in the field of extraction, can solve problems such as difficult back extraction and easy precipitation of heavy rare earth extracts, and achieve the effects of improving the extraction separation coefficient, good interface phenomena, and saving acid and alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Take 2,4,4-trimethylpentylphosphonic acid-2,4,4-trimethylpentyl ester and bis(2,4,4-trimethylpentyl)phosphonic acid (Code C272), to The volume ratio is 0.5:0.5 to form a mixed extractant. It is mixed with sulfonated kerosene to form an organic phase, and the volume ratio of the mixed extractant to sulfonated kerosene in the organic phase is 0.1:0.9.

[0069] Take the Tm-Yb-Lu enrichment, add concentrated hydrochloric acid, and prepare a raw material solution, the composition of which is ΣREO=0.036 mol / L, HCl=0.20 mol / L, Tm:Yb:Lu=10:80:10.

[0070] The organic phase with a volume ratio of 1:1 was mixed with the raw material solution, extracted at room temperature for 10 minutes, and the extraction stage was 1 stage. After the extraction is completed, the adjacent element separation coefficient β is calculated by the method of the present invention, and it can be known that under the current conditions, the separation coefficient β of the mixed extractant to Tm and Yb Y...

Embodiment 2

[0080] Prepare the organic phase: take 2,4,4-trimethylpentylphosphonic acid-2,4,4-trimethylpentyl ester, di(2,4,4-trimethylpentyl)phosphonic acid and trimethylpentylphosphonic acid (2,4,4-trimethylpentyl) phosphate, the volume ratio is 0.45:0.45:0.10 to form a mixed extractant. It is mixed with sulfonated kerosene to form an organic phase, and the volume ratio of the mixed extractant to sulfonated kerosene in the organic phase is 0.45:0.55.

[0081] Preparation of raw material solution: take the Yb-Lu enrichment, add concentrated hydrochloric acid to dissolve at a solid-to-liquid ratio of 10:1.5, and prepare a raw material solution, the composition of which is ∑REO=1.2 mol / liter, pH=1, Yb:Lu=10: 1.

[0082] Fractional extraction and back extraction: Fractional extraction and back extraction are carried out in a 0.25L mixing and settling tank, and the residence time of the aqueous phase and the organic phase in the mixing chamber is 8 minutes. The number of extraction stages ...

Embodiment 3

[0084] Prepare the organic phase: take 2,3,4-trimethylpentylphosphonic acid-2,3,4-trimethylpentyl ester, di(2,3,4-trimethylpentyl)phosphonic acid and trimethylpentylphosphonic acid (2,3,4-trimethylpentyl) phosphate, the volume ratio is 0.45:0.45:0.10 to form a mixed extractant. It is mixed with sulfonated kerosene to form an organic phase, and the volume ratio of the mixed extractant to sulfonated kerosene in the organic phase is 0.3:0.7.

[0085] Prepare the raw material solution: take the scandium enrichment recovered from the tailings of the southern ion-type mine, of which scandium oxide accounts for 85%, and the impurities are mainly heavy rare earths. The scandium enriched material is dissolved in nitric acid at a solid-to-liquid ratio of 10:1.5 to prepare a raw material solution, the composition of which is ∑REO=0.35 mol / liter and pH=0.5.

[0086] Fractional extraction and back-extraction: Fractional extraction and back-extraction are carried out in a 0.25L mixed-settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com