An extractant and adsorbent containing effective functional groups and its application in the extraction and separation of thorium metal

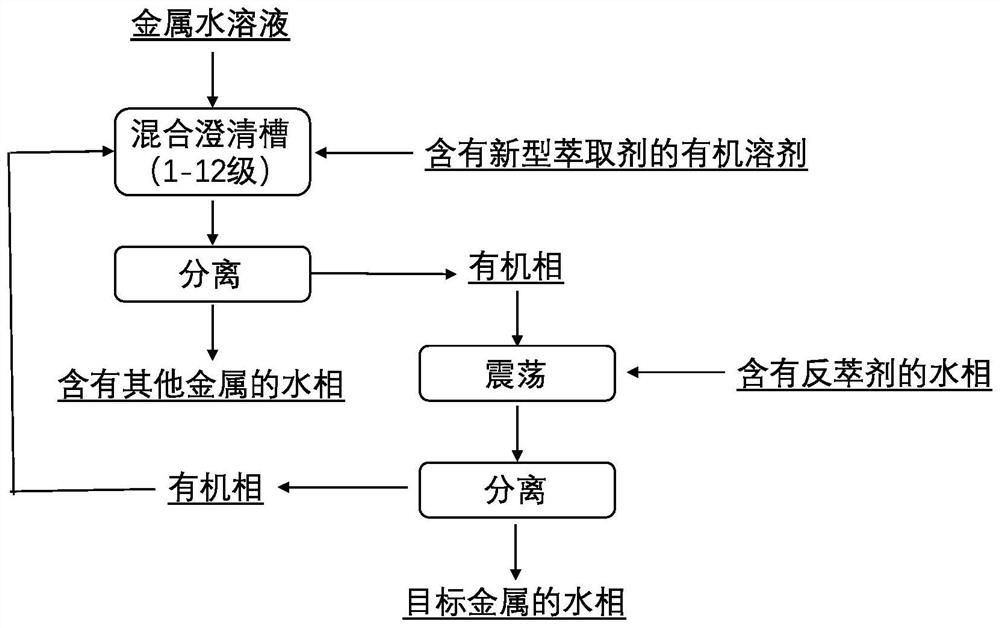

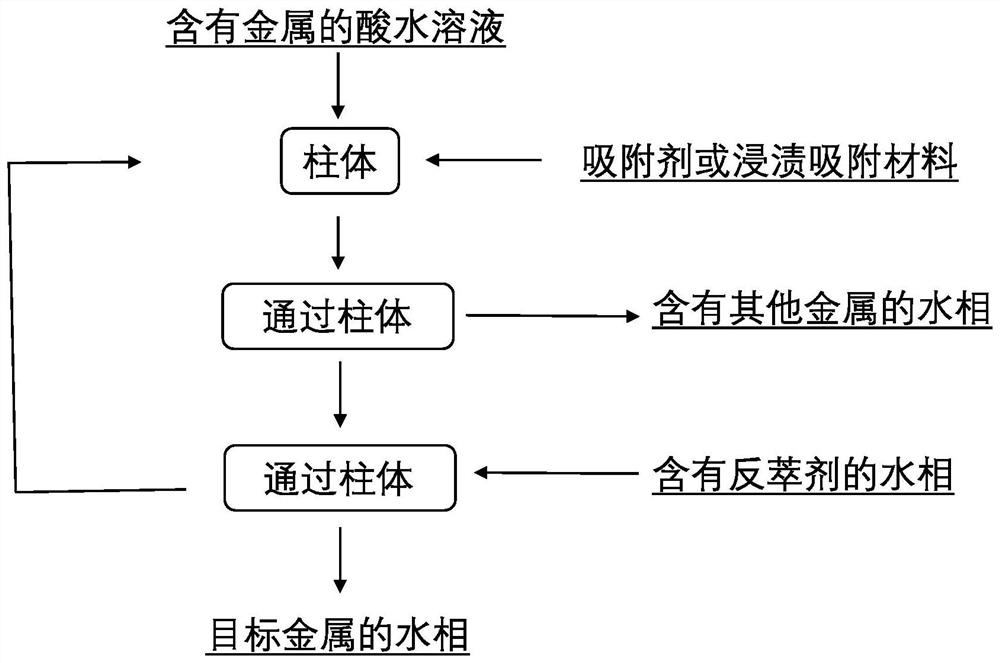

An adsorbent and extractant technology, applied in the field of extraction and separation of radioactive elements, can solve problems such as inability to remove completely, and achieve the effects of improved reusability, stable chemical structure, and expanded separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

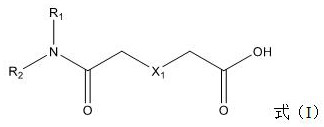

[0071] The present invention also provides the preparation method of above-mentioned extractant, according to the type difference of extractant, the preparation method of described extractant is as follows:

[0072] In a preferred embodiment of the present invention, the extractant (E1 ) and (E 2 ) preparation method comprises the steps:

[0073] Compound shown in formula (IV) and R 1 R 2 NH is a raw material, and at a certain temperature, reacts to prepare an extractant (E 1 ) or (E 2 );

[0074]

[0075] Among them, X 1 , R 1 , R 2 is defined as above.

[0076] In a preferred embodiment of the present invention, the extractant (E 1 ) and (E 2 ) preparation method specifically comprises the steps:

[0077] 1) compound shown in formula (IV) and R respectively 1 R 2 NH is dissolved in an organic solvent, where, X 1 , R 1 , R 2 as defined above;

[0078] 2) The above two solutions are mixed and reacted to prepare the extractant (E 1 ) or (E 2 ).

[0079] W...

Embodiment 1

[0162] Embodiment 1 extractant (E 1-1 ) Synthesis of -1

[0163] Weigh 1.52g (13.1mmol) diglycolic anhydride and 2.87g (11.9mmol) R 1 R 2 NH(R 1 , R 2 selected from isooctyl), which were dissolved in 20mL of dichloromethane organic solvent respectively; the two solutions were mixed and reacted at 25°C; during the reaction, the mixed solution gradually became clear, and when it was completely clear, the reaction Complete (about reaction 12h), make extraction agent shown in formula (I) (wherein, X 1 for -O-, R 1 and R 2 The same is isooctyl); the prepared extractant is washed with high-purity deionized water to remove impurities, and then magnesium sulfate is added to the washed product to filter to obtain a water-free product, and the processed product is rotated The organic solvent was removed by evaporating and condensing apparatus, and then dried in a vacuum oven at 75°C for 12 hours, so as to obtain a high-purity extractant. Wash the prepared extractant several time...

Embodiment 2

[0165] Embodiment 2 extractant (E 1-2 ) Synthesis of -2

[0166] Weigh 3.78g (28.2mmol) of diglycolic acid and dissolve in 20ml of acetic anhydride, heat to 140°C on a magnetic heating stirrer and stir to reflux. During the reaction, the solid gradually dissolves and the solution gradually becomes clear, and stops after 4 hours For the reaction, excess acetic anhydride and acetic acid formed by the reaction were removed by a rotary evaporator condenser, and placed in a vacuum oven at 80°C for 24 hours, and the product was diglycolic anhydride. The yield was 93%.

[0167] The above diglycolic anhydride and 2.87g (11.9mmol) R 1 R 2 NH(R 1 , R 2 selected from isooctyl), which were dissolved in 20mL of dichloromethane organic solvent respectively; the two solutions were mixed and reacted at 25°C; during the reaction, the mixed solution gradually became clear, and when it was completely clear, the reaction Complete (about reaction 12h), make extraction agent shown in formula (I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com