Extracting agent for rare earth extraction separation, preparing method thereof and extraction separation method using same

An extraction agent and extraction technology, applied in the direction of improving process efficiency, etc., can solve problems such as insufficient separation coefficient, decline in extraction capacity, and increase in economic cost, and achieve the effect of good extraction phenomenon, maintenance of separation coefficient, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

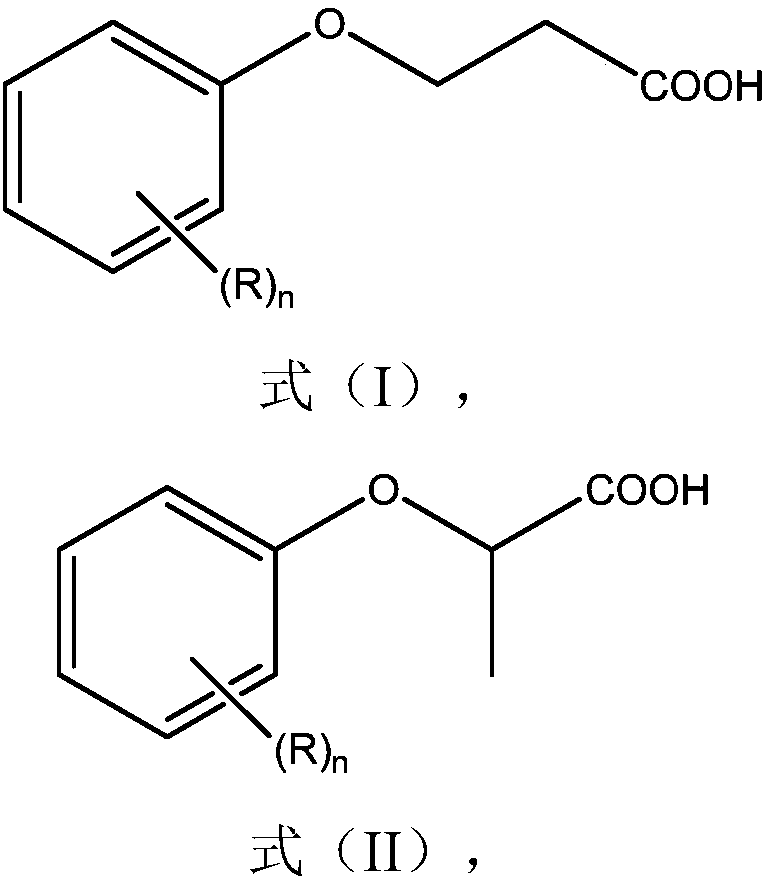

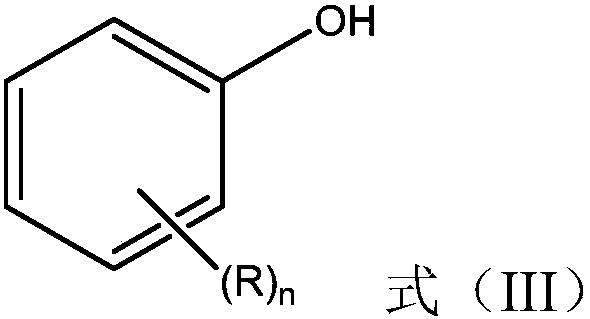

[0079] 1) Synthetic extractant ortho-sec-octylphenoxy substituted n-propionic acid

[0080] Get 2.17 kilograms of 3-chloro-n-propionic acid, add 5 liters of water, slowly add 1.4 kilograms of potassium carbonate, adjust the pH value to 9, and obtain 3-chloro-n-propionic acid sodium solution; Under stirring conditions, add 4.13 kg of ortho-sec-octylphenol, and slowly add 0.46 kg of sodium metal. After the reaction is complete, heat up to 90 degrees Celsius and keep warm for half an hour to obtain a solution of ortho-sec-octylphenol sodium. Turn on stirring and heating, raise the temperature to 110 degrees Celsius, slowly add the 3-chloro-n-propionate sodium solution into the ortho-second-octylsodium phenolate solution, cool to room temperature after reacting for 1 hour, add 6 moles per liter of hydrochloric acid 5 1 liter for acidification, after washing 4 times, rotary evaporation to remove solvent, 160 degrees centigrade vacuum distillation, to obtain ortho-secondary octylphe...

Embodiment 2

[0096] 1) Synthetic extractant p-n-nonylphenoxy substituted isopropionic acid

[0097]Take 2.17 kg of 2-chloropropionic acid, add 5 liters of water, slowly add 1.4 kg of potassium carbonate, adjust the pH value to 9, and obtain a 2-chloropropionic acid sodium solution; Next, add 4.47 kg of p-n-nonylphenol, slowly add 2 kg of sodium hydroxide and raise the temperature to 90 degrees Celsius, react for half an hour, heat up to 110 degrees Celsius, slowly add 2-chloropropionate sodium solution to the p-normal In sodium nonylphenolate solution, react for 1 hour and then cool to room temperature, add 5 liters of hydrochloric acid with 6 moles per liter for acidification, wash 4 times with water, remove solvent by rotary evaporation, and distill under reduced pressure at 170 degrees Celsius to obtain para-n-nonyl The phenoxy substituted isopropionic acid product has a yield of 96.3%. After acid-base titration and NMR characterization, the purity of p-n-nonylphenoxy substituted isopro...

Embodiment 3

[0106] 1) Synthetic extractant p-n-nonylphenoxy substituted isopropionic acid

[0107] With embodiment 2.

[0108] 2) Prepare the organic phase: take 460 ml of p-n-nonylphenoxy substituted isopropionic acid obtained in step 1), mix it with 100 ml of tributyl phosphate and 260# solvent kerosene to obtain the organic phase, and extract The agent concentration is 0.80 mol / liter, and the volume ratio of tributyl phosphate is 10%. Add 88 milliliters of concentrated ammonia water to make the degree of saponification of the extractant in the organic phase reach 80%.

[0109] 3) Preparation of yttrium-containing rare earth feed liquid

[0110] With embodiment 2.

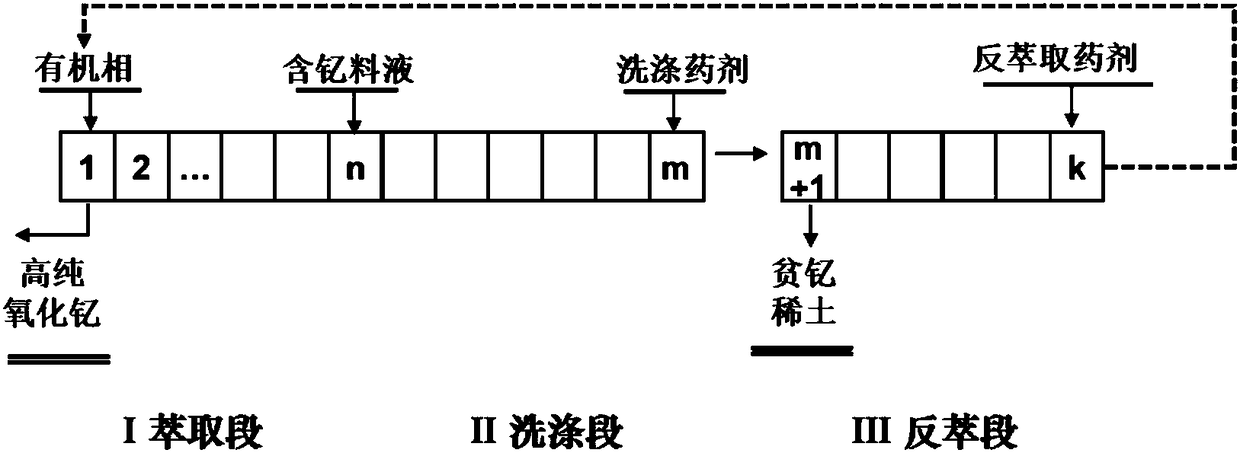

[0111] 4) Extraction and separation: such as figure 1 As shown, the whole extraction process was carried out in a mixed-settler tank, including 20 stages of extraction (n=60), 15 stages of washing (m=30) and 6 stages of back extraction (k=6). The mass flow ratio of the organic phase, the rare earth material liquid conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com