Method for quantitatively analyzing efficiency of metalloporphyrin MOFs materials in separating CO2/CH4

A metalloporphyrin, separation efficiency technology, applied in the direction of adsorption purification/separation, special data processing applications, instruments, etc., can solve the problems of strict operating environment requirements, non-reusable, complicated operation, etc., and achieve the effect of overcoming complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

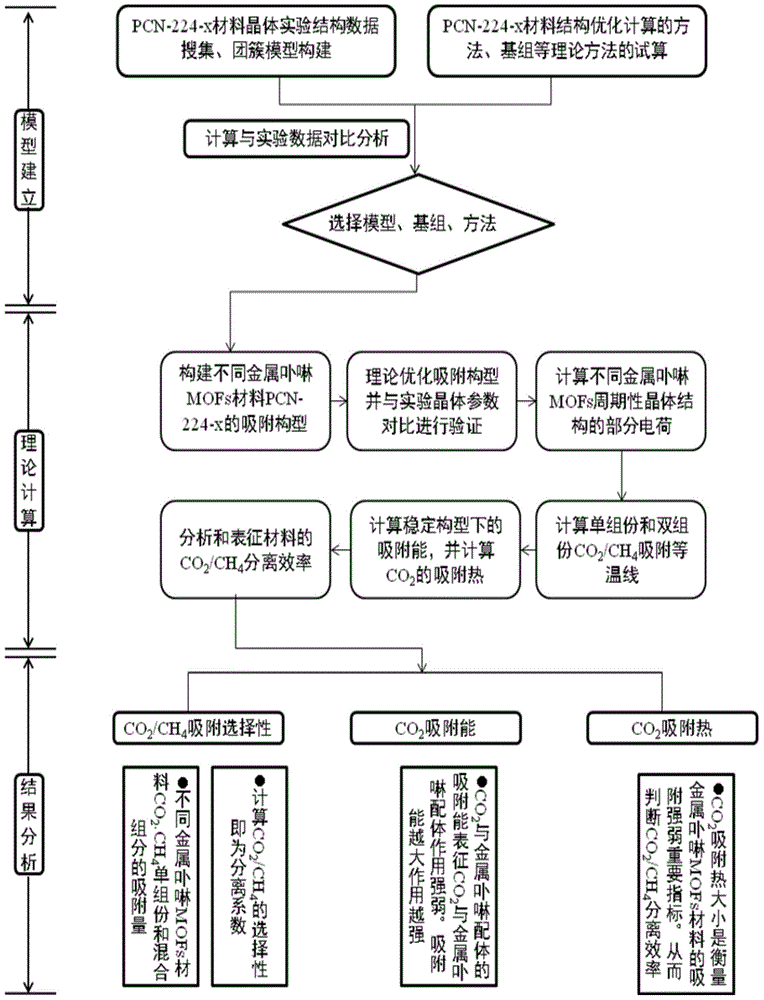

[0028] Example 1 Quantitative analysis of CO in metalloporphyrin MOFs material PCN-224-x (x=Ni, Fe, Co, Mn, Mg, Zr) 2 / CH 4 separation efficiency

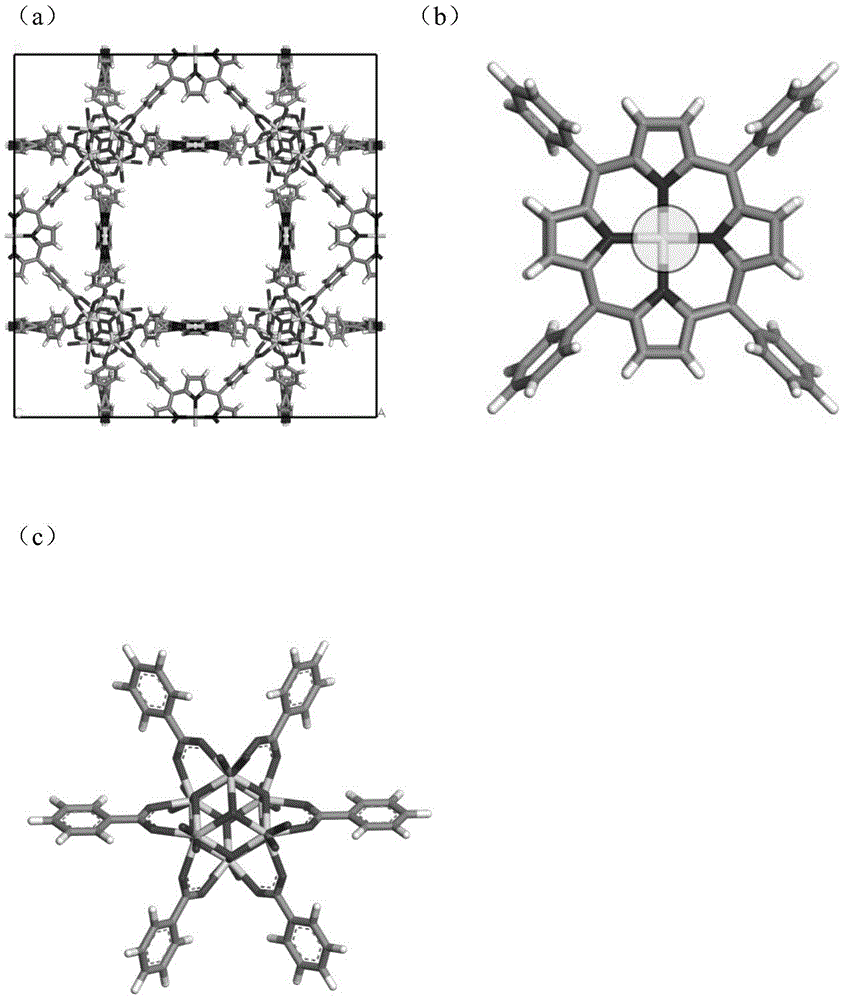

[0029] (1) Construction of PCN-224-x material cluster model

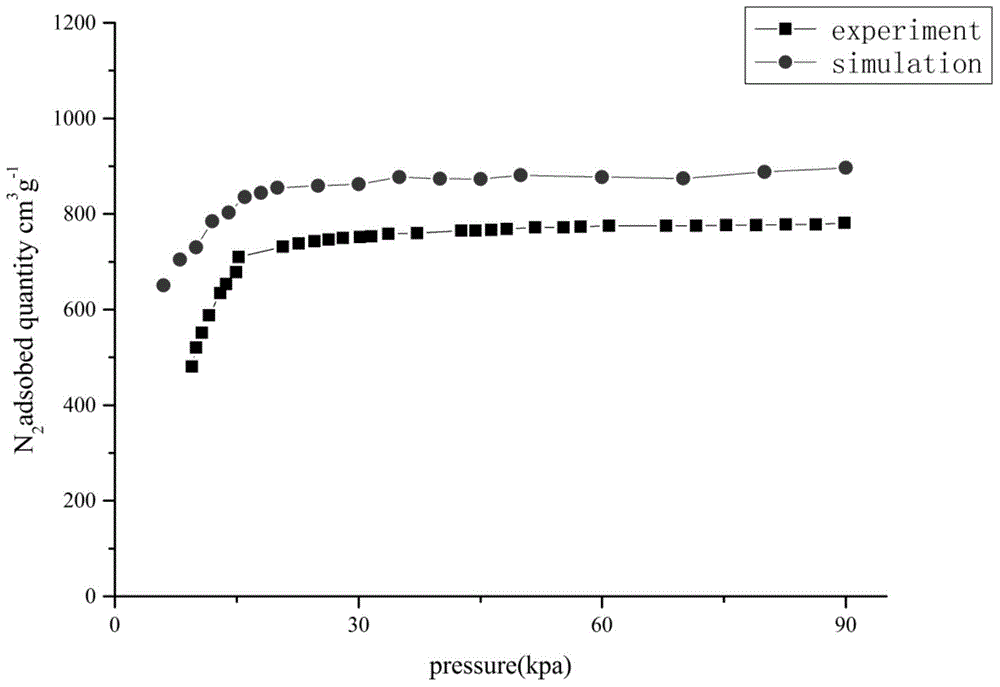

[0030] PCN-224 material is a newly synthesized metalloporphyrin MOFs material, it has Im-3m cubic crystal system space group structure, and its unit cell parameters are by Zr 6 Metal center group and Zr metalloporphyrin ligand self-assembled to form, the pore volume is 1.59cm 3 / g, the aperture size is Its unit cell such as figure 2 Shown in (a), molecular formula is [C 576 h 288 N 48 o 256 Zr 60 ]. Import the PCN-224 experimental crystal data structure into MS5.0 software, and intercept Zr metalloporphyrin ligand and Zr 6 Metal center groups such as figure 2 (b) and figure 2 (c). The Zr metalloporphyrin ligand is saturated with benzene, and the Zr 6 The metal center group is treated with proton saturation.

[0031] To study the effect of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com