Modified rice dialdehyde starch retanning filler for leather and preparation method of filler

A technology of dialdehyde starch and rice starch, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, application, etc. Tannin penetration, unsatisfactory effect and other problems, to achieve the effect of short preparation cycle, simple process operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

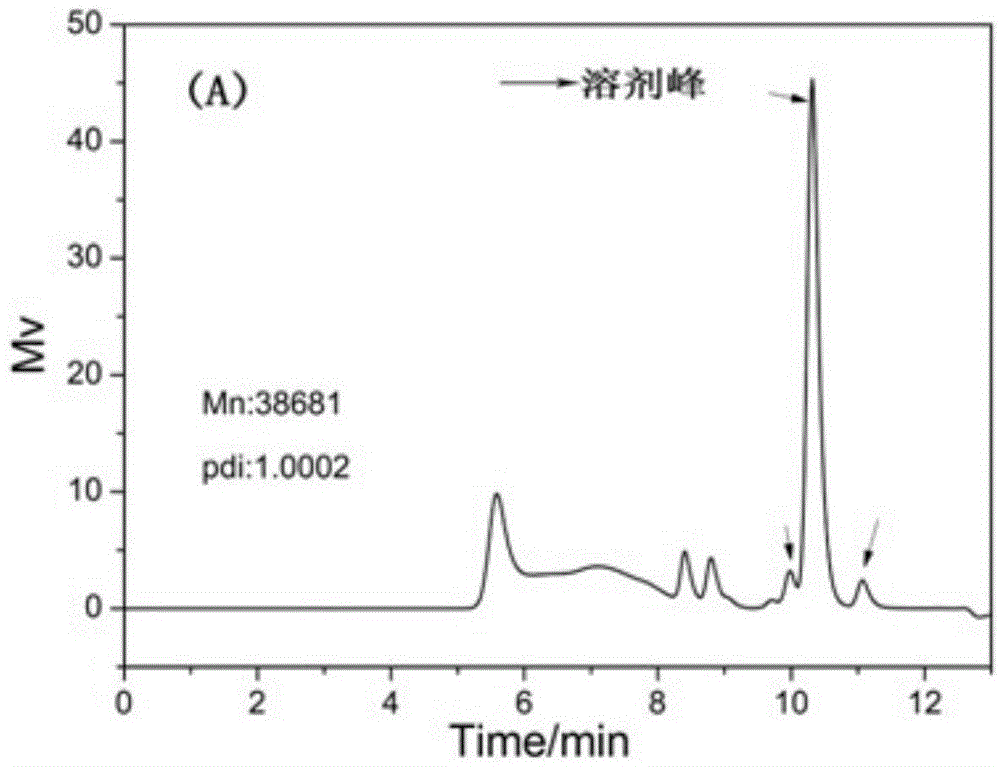

Embodiment 1

[0027] (1) Mix 29.24g of raw rice starch with 500mL of periodic acid solution with a solubility of 0.5mol / L at room temperature, stir for 5 minutes, adjust the pH value to 3.5 with sulfuric acid, react in a constant temperature water bath at 35°C for 4 hours, and discharge the material. Wash with absolute ethanol and water alternately, and dry at 40°C to obtain rice dialdehyde starch;

[0028] (2) Prepare 65wt% sulfuric acid aqueous solution, take 1.68g as degradation agent;

[0029] (3) Mix 20g of the above-prepared rice dialdehyde starch with 60g of water at room temperature to obtain an emulsion; add the degradation agent aqueous solution obtained in (2) dropwise into the emulsion, stir at 40~50°C for 30min, and obtain the rice dialdehyde starch filler premix;

[0030] (4) Transfer the rice dialdehyde starch filler premix obtained in (3) into a 100mL hydrothermal reaction kettle, the reaction temperature is 100°C, and the reaction time is 2 hours. Soda ash with a mass rat...

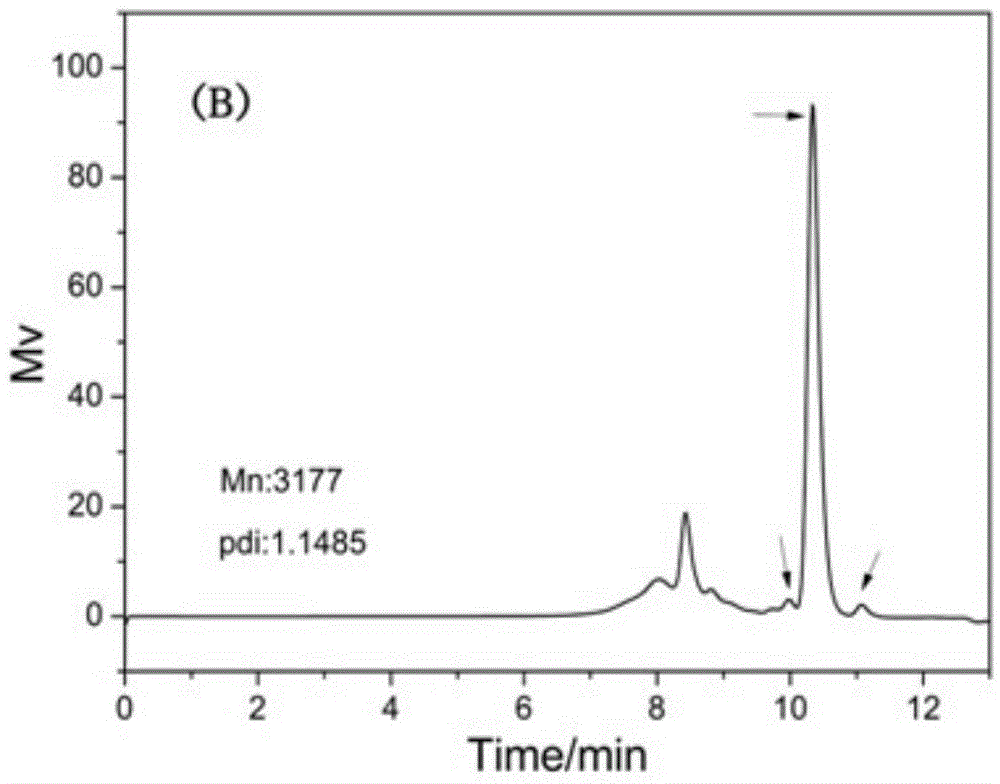

Embodiment 2

[0033] (1) Mix 292.43g of raw rice starch with 500mL of periodic acid solution with a solubility of 0.5mol / L at room temperature, stir for 10min, adjust the pH value to 3.5 with sulfuric acid, react in a constant temperature water bath at 35°C for 4h, and discharge. Wash with absolute ethanol and water alternately, and dry at 40°C to obtain rice dialdehyde starch;

[0034] (2) Prepare 80wt% lactic acid aqueous solution and 65wt% sulfuric acid aqueous solution respectively, take 1.20g lactic acid aqueous solution and 1.0g sulfuric acid aqueous solution as mixed acid degradation agent;

[0035] (3) Mix 20g of the above-prepared rice dialdehyde starch with 60g of water at room temperature to obtain an emulsion; add the degradation agent aqueous solution obtained in (2) dropwise into the emulsion, stir at 40~50°C for 30min, and obtain the rice dialdehyde starch filler premix;

[0036] (4) Transfer the rice dialdehyde starch filler premix obtained in (3) into a 100mL hydrothermal ...

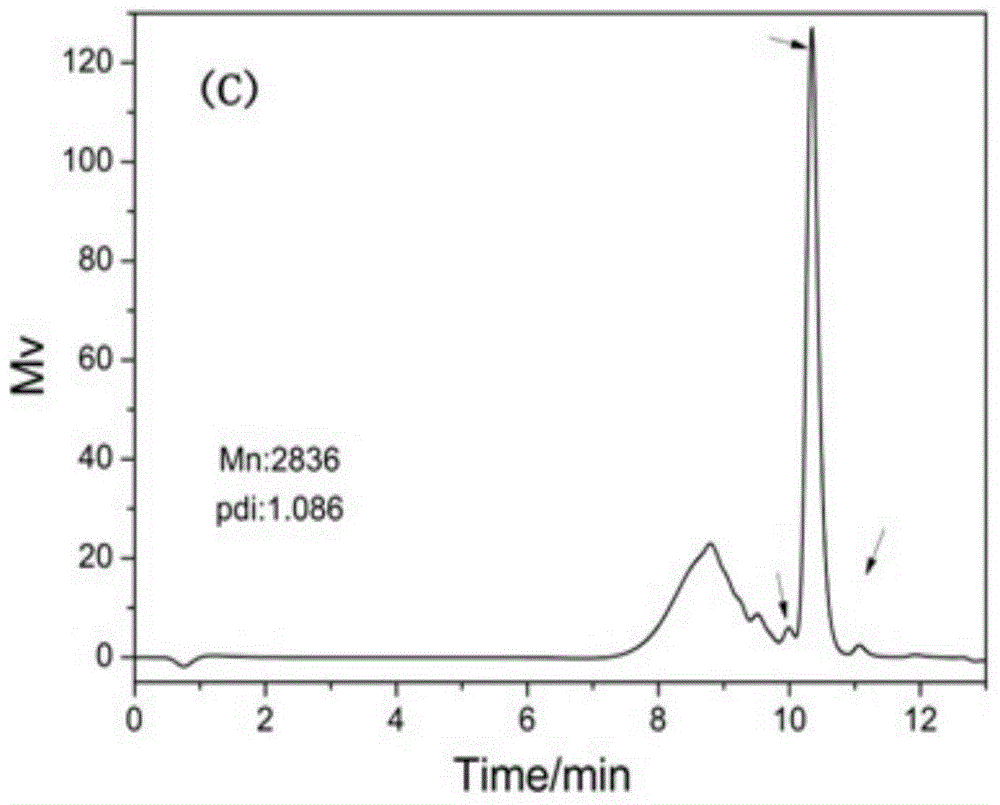

Embodiment 3

[0039] (1) Mix 62.66g of raw rice starch with 500mL of sodium periodate solution with a solubility of 0.5mol / L at room temperature, stir for 5 minutes, adjust the pH value to 3.5 with sulfuric acid, react in a constant temperature water bath at 35°C for 4 hours, and discharge , washed alternately with absolute ethanol and water, and dried at 40°C to obtain rice dialdehyde starch;

[0040](2) Prepare 80wt% lactic acid aqueous solution, take 2.0g as degradation agent;

[0041] (3) Mix 20g of the above-prepared rice dialdehyde starch with 60g of water at room temperature to obtain an emulsion; add the degradation agent aqueous solution obtained in (2) dropwise into the emulsion, stir at 40~50°C for 30min, and obtain the rice dialdehyde starch filler premix;

[0042] (4) Transfer the rice dialdehyde starch filler premix obtained in (3) into a 100mL hydrothermal reaction kettle, the reaction temperature is 100°C, and the reaction time is 2 hours. Soda ash with a mass ratio of 20%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com