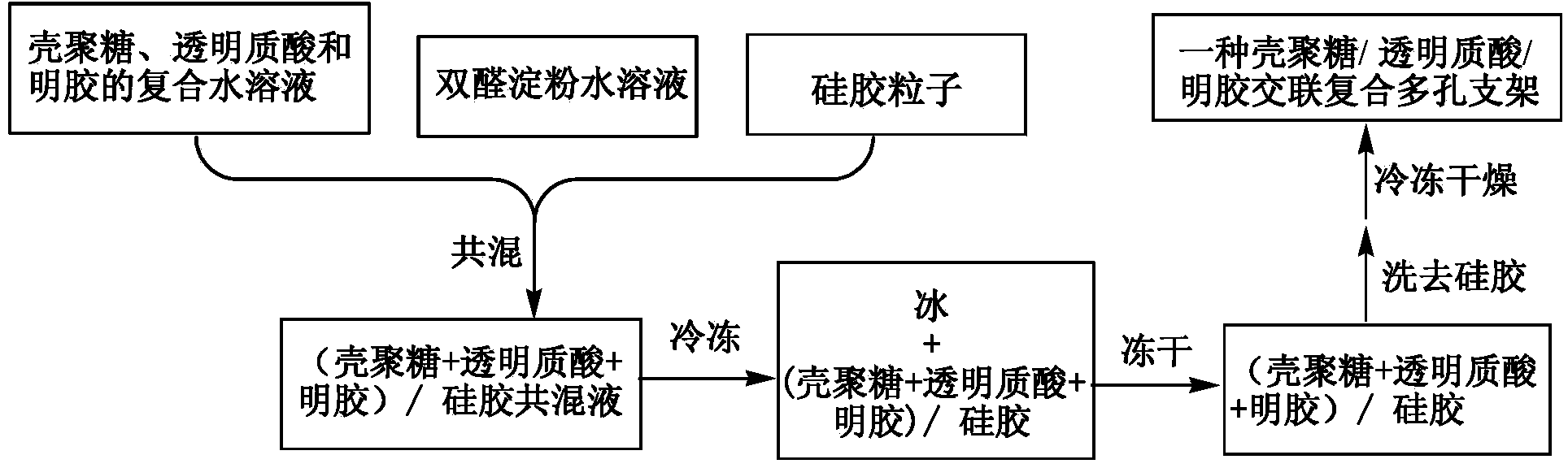

Method for preparing chitosan/hyaluronic acid/gelatin crosslinked composite porous stent

A technology of hyaluronic acid and porous scaffolds, which is applied in medical science, prosthesis, etc., can solve problems such as weak mechanical strength, and achieve the effects of high porosity, simple and convenient process, and large pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare 2% chitosan aqueous solution, 2% hyaluronic acid aqueous solution, 2% gelatin aqueous solution and 2% dialdehyde starch aqueous solution with mass percentage respectively;

[0026] The above-mentioned chitosan aqueous solution, hyaluronic acid aqueous solution and gelatin aqueous solution were blended in a mass ratio of 60:10:30, and then the dialdehyde starch aqueous solution was added. Among them, the total mass of chitosan, hyaluronic acid and gelatin was compared with the dialdehyde The mass ratio of starch is 50:1, after stirring evenly, cross-linking reaction for 12 hours, defoaming, to obtain defoamed chitosan / hyaluronic acid / gelatin cross-linking composite solution;

[0027] Grind silica gel particles, and screen silica gel particles with a particle size of 120-150 mesh with a screen;

[0028] Weigh 5 g of the above-mentioned defoamed chitosan / hyaluronic acid / gelatin cross-linking composite solution, 1 g of the above-mentioned silica gel particles, and the ...

Embodiment 2

[0031] Same as Example 1, but in step (1), the concentrations of the chitosan solution, hyaluronic acid solution, gelatin solution and dialdehyde starch solution are all changed from 2% to 3%, and the others remain unchanged.

Embodiment 3

[0033] Same as Example 1, but in step (1), the concentrations of chitosan solution, hyaluronic acid solution, gelatin solution and dialdehyde starch solution are all changed from 2% to 1%, and the others remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com