Wheat protein/methyl cellulose composite edible film and preparation method thereof

A methylcellulose and protein technology, which is applied in the field of wheat protein/methylcellulose composite edible film and its preparation, can solve the problems of toxicity, unfavorable personal safety, unfavorable film-forming operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take by weighing 15g gluten powder (Shanghai Wangwei Food Co., Ltd. product) and add 285g weight concentration and be 10% ammoniacal liquor, be made into the suspension liquid that protein weight concentration is 5%, standby; Take by weighing 15g methyl cellulose (M450, Sinopharm Chemical Reagent Co., Ltd.) adding 735g weight concentration is 10% ammoniacal liquor, is made into the solution that methyl cellulose weight concentration is 2%, for subsequent use; In deionized water, prepare a solution with a concentration of 1% by weight and set aside.

[0032] Take 20g of gluten suspension and 12.5g of methylcellulose solution and mix them, add 0.42g of glycerin and 1g of dialdehyde starch solution in turn under electromagnetic stirring, stir evenly, pour the solution on a smooth polyester film, and dry it at room temperature for 5 Day, heat treatment at 130°C for 30min after stripping the film.

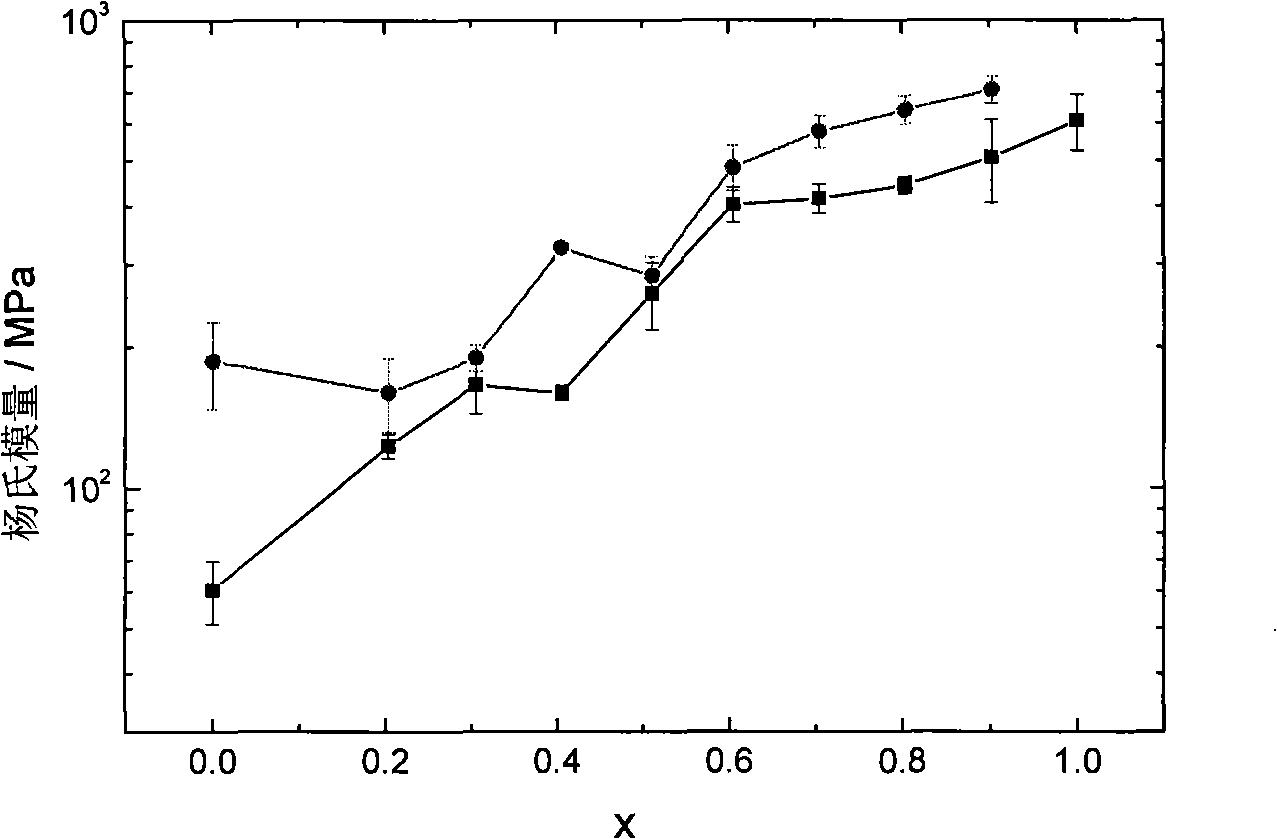

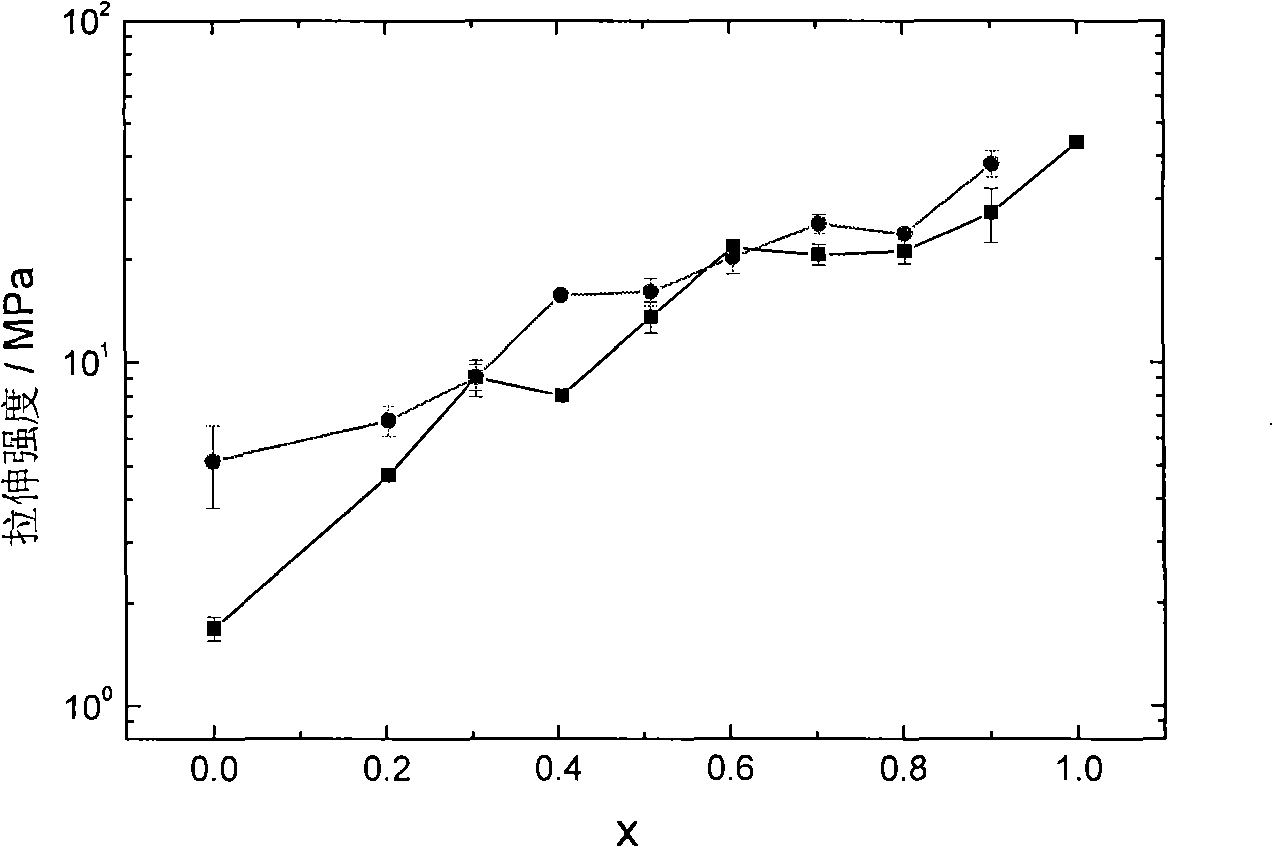

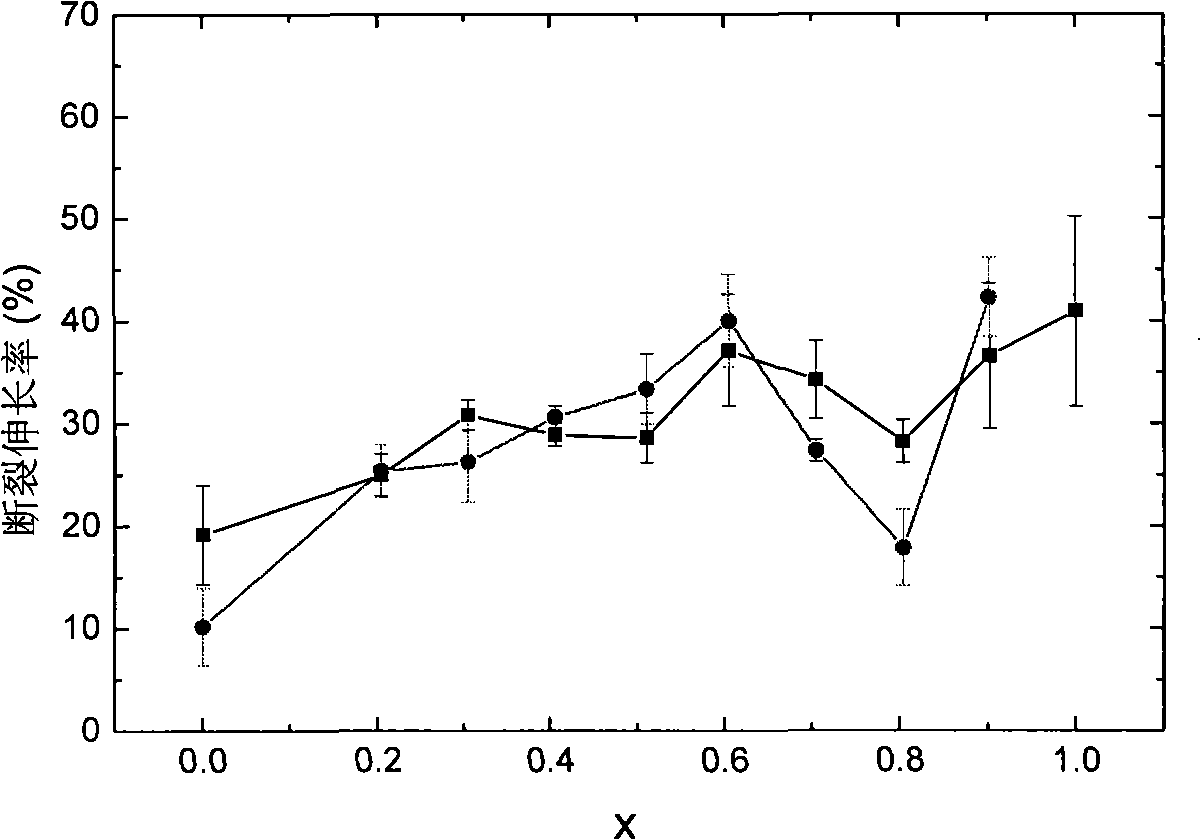

Embodiment 2~8

[0034] The dosage of gluten suspension is 17.5g, 15g, 12.5g, 10g, 7.5g, 5.0g, 2.5g respectively, and the corresponding dosage of methylcellulose solution is 18.75g, 25g, 31.25g, 37.5g, 43.75g, 50g, 56.25g, all the other conditions are with embodiment 1.

Embodiment 9~16

[0036] The film was heat-treated at 100° C. for 10 minutes, and the rest of the conditions were the same as in Examples 1-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com