Nano-crystalline cellulose/gelatin composite aerogel and application thereof

A nanocellulose and composite aerogel technology, applied in aerogel preparation, colloid chemistry, colloid chemistry, etc., can solve the problems of loss of mechanical properties and high degradation rate, and achieve good biocompatibility and degradability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of nanocellulose dispersion by TEMPO-mediated oxidation

[0046] First, 10 g of dry fiber slurry was soaked in 500 mL of deionized water, followed by adding TEMPO (0.16 g) and NaBr (1.6 g) and stirring continuously at room temperature to make it evenly mixed. Then add 120mL NaClO (7.6mmol / L) solution to start the oxidation reaction. During the reaction, the pH value of the entire reaction system was maintained between 10-10.5 until the pH value no longer decreased, and 50 mL of ethanol was added to terminate the reaction. Soak the reacted slurry in 0.1mol / L HCl for acidification and washing. Then the washed slurry was quantified to 1%, the pH value of the quantified solution was adjusted to 10 again, and finally ultrasonic treatment was performed for 20 minutes under ultrasonic waves to obtain a uniform and transparent nanocellulose dispersion.

[0047] 2. Preparation of nanocellulose / gelatin composite airgel, the steps are as follows:

[0048] 1) The ...

Embodiment 2

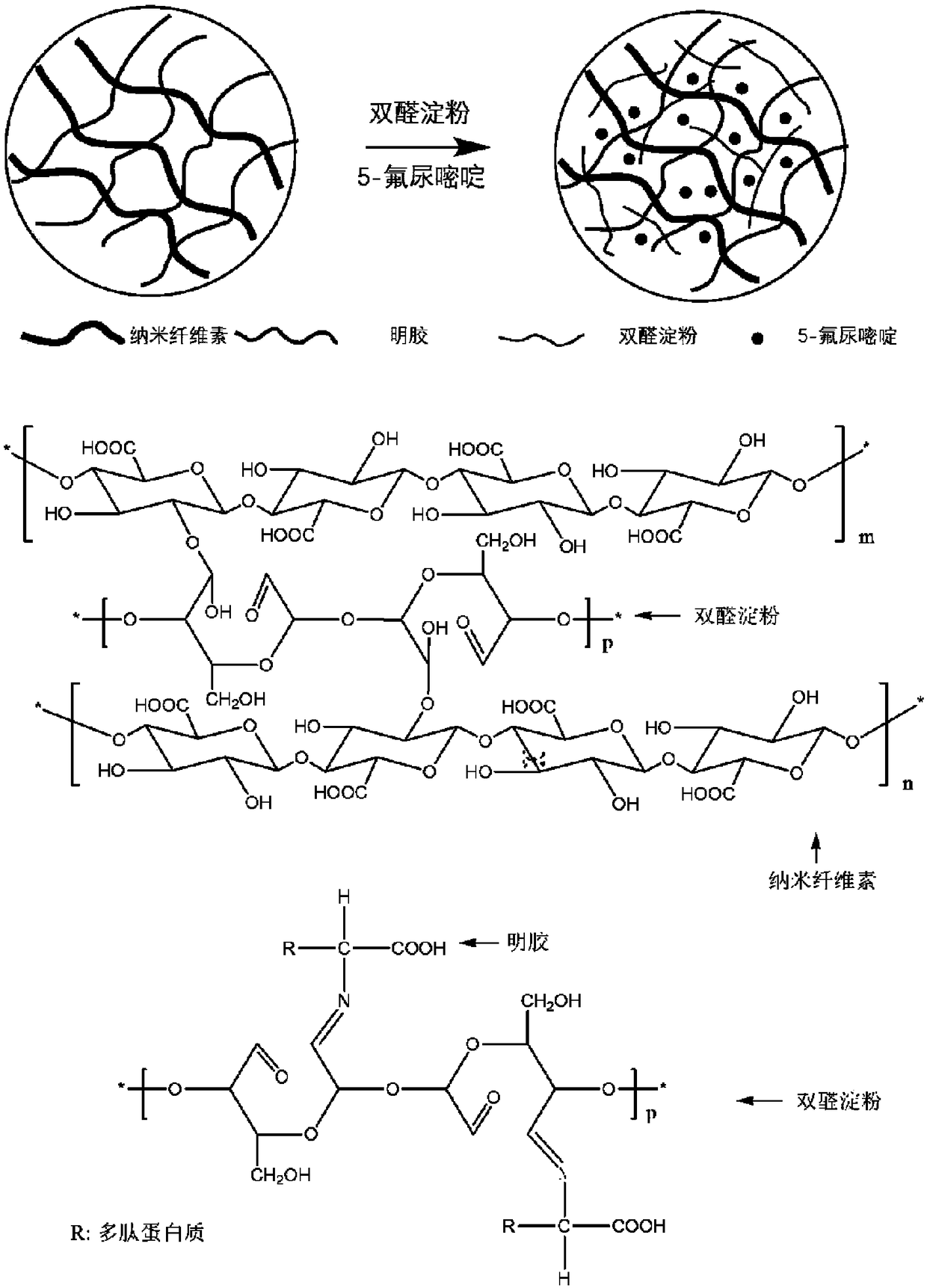

[0072] Example 2 Preparation of nanocellulose / gelatin composite airgel loaded with 5-fluorouracil

[0073] A cylindrical HDPE cup (diameter 40 mm, height 50 mm) was used as a mold for preparing the composite airgel. The nanocellulose and gelatin solution were blended at a mass ratio of 3:7, and stirred rapidly with a magnetic stirrer at 60 °C for 2 h to disperse evenly. Add 2.5wt% (relative to the total mass of airgel) of 5-fluorouracil, and then add 10wt% gelatinized dialdehyde starch (relative to the total mass of nanocellulose and gelatin) to the homogeneously mixed nanocellulose and gelatin The mixed solution was reacted at 90°C for 4 h to obtain a uniform and transparent solution. The cross-linked sample solution was pre-cooled at 4°C for 12 hours to form a hydrogel, then quickly frozen with liquid nitrogen, and freeze-dried in a freeze dryer at -91°C for 3 days. Finally, the obtained airgel was cured in an oven at 110° C. for 2 hours to obtain a nanocellulose / gelatin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com