Biodegradable heat shrinking film

A heat-shrinkable film and biodegradable technology, applied in the field of heat-shrinkable film, can solve the problem of difficult biodegradation of heat-shrinkable film, and achieve the effect of good physical properties and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

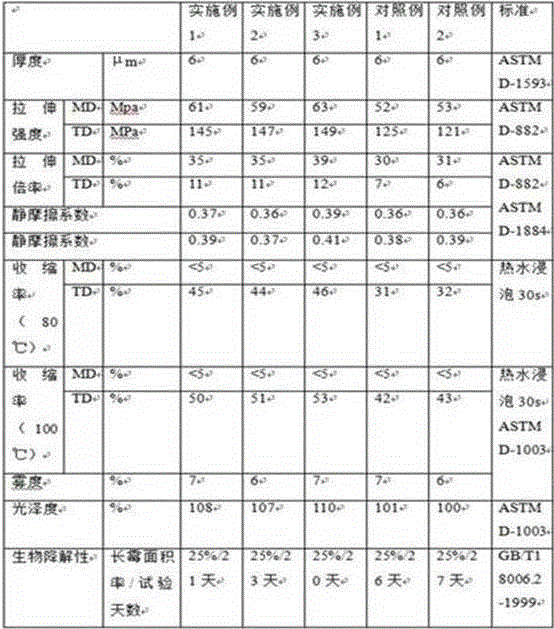

Examples

Embodiment 1

[0034] A biodegradable heat-shrinkable film, which is prepared through the following steps:

[0035] In the first step, by weight, 10 parts of dialdehyde starch, 4 parts of polyvinyl alcohol, 3 parts of chitosan and 1 part of sodium carboxymethyl cellulose are added to the reactor, and after reacting under sealed conditions, the improved Reactive dialdehyde starch, reaction time 40min, reaction temperature 80°C;

[0036] In the second step, using a stirring mixer, 150 parts of polylactic acid with a weight average molecular weight of 3 to 300,000, 15 parts of high density polyethylene with a weight average molecular weight of 4 to 500,000, and a weight average molecular weight of 6,000 to 100,000 15 parts of polybutylene adipate, 10 parts of modified dialdehyde starch, 5 parts of polypropylene glycol with a molecular weight of 1000-2000, 1 part of plasticizer ethylene glycol, 1 part of crosslinking agent acetaldehyde, compatibilizer Agent ethylene acrylic acid copolymer 1 par...

Embodiment 2

[0039] A biodegradable heat-shrinkable film, which is prepared through the following steps:

[0040] In the first step, by weight, 20 parts of dialdehyde starch, 7 parts of polyvinyl alcohol, 5 parts of chitosan and 3 parts of sodium carboxymethyl cellulose are added to the reactor, and after reacting under sealed conditions, the improved Reactive dialdehyde starch, reaction time 60min, reaction temperature 90°C;

[0041] In the second step, using a stirring mixer, 200 parts of polylactic acid with a weight average molecular weight of 3 to 300,000, 25 parts of high density polyethylene with a weight average molecular weight of 4 to 500,000, and a weight average molecular weight of 6,000 to 100,000 25 parts of polybutylene adipate, 30 parts of modified dialdehyde starch, 15 parts of polypropylene glycol with a molecular weight of 1000-2000, 4 parts of plasticizer ethylene glycol, 4 parts of crosslinking agent acetaldehyde, compatibilizer Agent ethylene acrylic acid copolymer 4 p...

Embodiment 3

[0044] A biodegradable heat-shrinkable film, which is prepared through the following steps:

[0045] In the first step, by weight, 15 parts of dialdehyde starch, 5 parts of polyvinyl alcohol, 4 parts of chitosan and 2 parts of sodium carboxymethyl cellulose are added to the reactor, and after reacting under sealed conditions, the improved Reactive dialdehyde starch, reaction time 50min, reaction temperature 85°C;

[0046] In the second step, using a stirring mixer, 170 parts by weight of polylactic acid with a weight average molecular weight of 3 to 300,000, 20 parts of high density polyethylene with a weight average molecular weight of 4 to 500,000, and 6,000 to 100,000 weight average molecular weight 20 parts of polybutylene adipate, 20 parts of modified dialdehyde starch, 10 parts of polypropylene glycol with a molecular weight of 1000-2000, 2 parts of plasticizer ethylene glycol, 2 parts of crosslinking agent acetaldehyde, compatibilizer 2 parts of ethylene acrylic acid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com