Guanidine salt grafted starch multifunctional papermaking additive and preparation method thereof

A technology of grafting starch and papermaking auxiliaries, applied in the direction of adding paper and reinforcing agents, etc., can solve problems such as harm to health, bacterial growth, and inability to impart antibacterial properties to paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

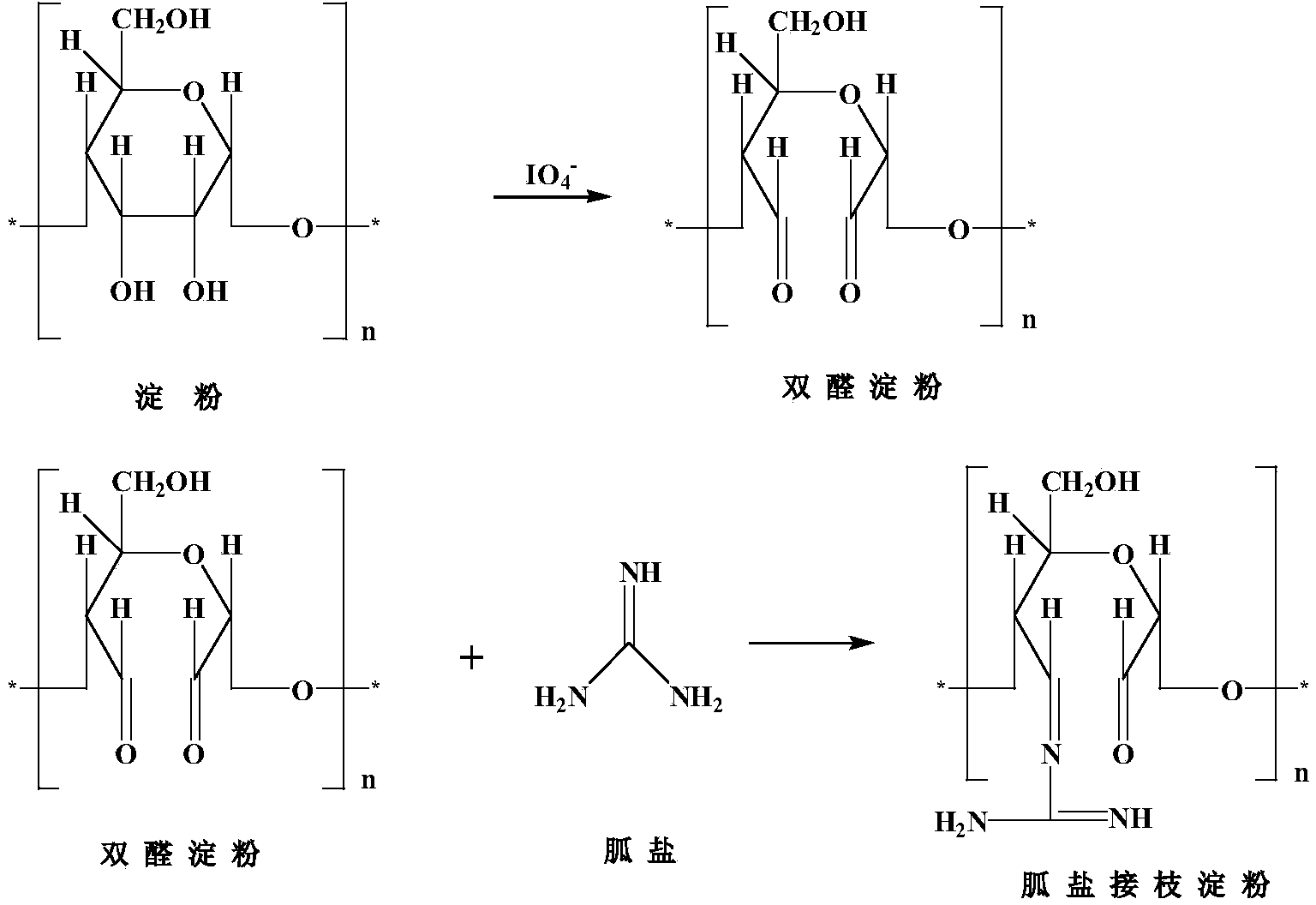

[0019] (1) Starch is added to 1 mol / L sodium periodate solution, heated and reacted at 30°C for 4 hours, the product is filtered, washed and dried to obtain dialdehyde starch; the mole of sodium periodate and starch The ratio is 1:1.

[0020] (2) Disperse the dialdehyde starch obtained in step (1) in distilled water, add guanidine hydrochloride and react at 30°C for 2 hours, filter, wash and dry the product to obtain guanidine salt grafted starch; the guanidine salt and bis The molar ratio of aldehyde starch is 1:1.

Embodiment 2

[0022] (1) Starch is added to 1.5 mol / L sodium periodate solution, heated and reacted at 40°C for 4h, the product is filtered, washed and dried to obtain dialdehyde starch; the mole of sodium periodate and starch The ratio is 1:1.2.

[0023] (2) Disperse the dialdehyde starch obtained in step (1) in distilled water, add guanidine hydrochloride and react at 50°C for 2 hours, filter, wash and dry the product to obtain guanidine salt grafted starch; the guanidine salt and bis The molar ratio of aldehyde starch is 1:5.

Embodiment 3

[0025] (1) Starch is added to 2 mol / L sodium periodate solution, heated and reacted at 50°C for 4 hours, and the product is filtered, washed and dried to obtain dialdehyde starch; the mole of sodium periodate and starch The ratio is 1:1.5.

[0026] (2) Disperse the dialdehyde starch obtained in step (1) in distilled water, add metformin hydrochloride (this proves that "metformin hydrochloride" can also be used in the present invention) and react at 60°C for 2 hours, filter, wash and dry the product to obtain Guanidine salt grafted starch; the molar ratio of the guanidine salt to dialdehyde starch is 1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com