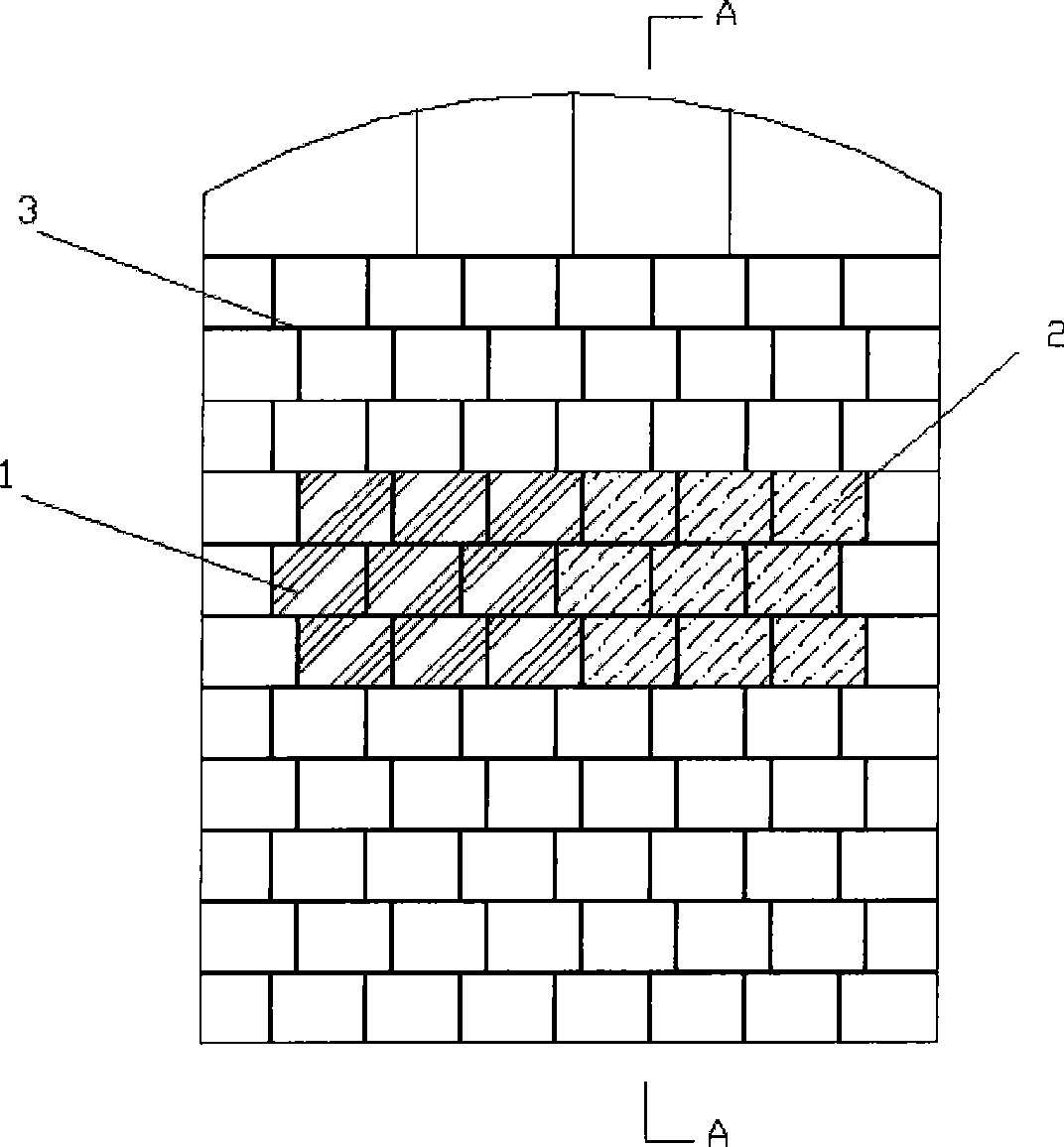

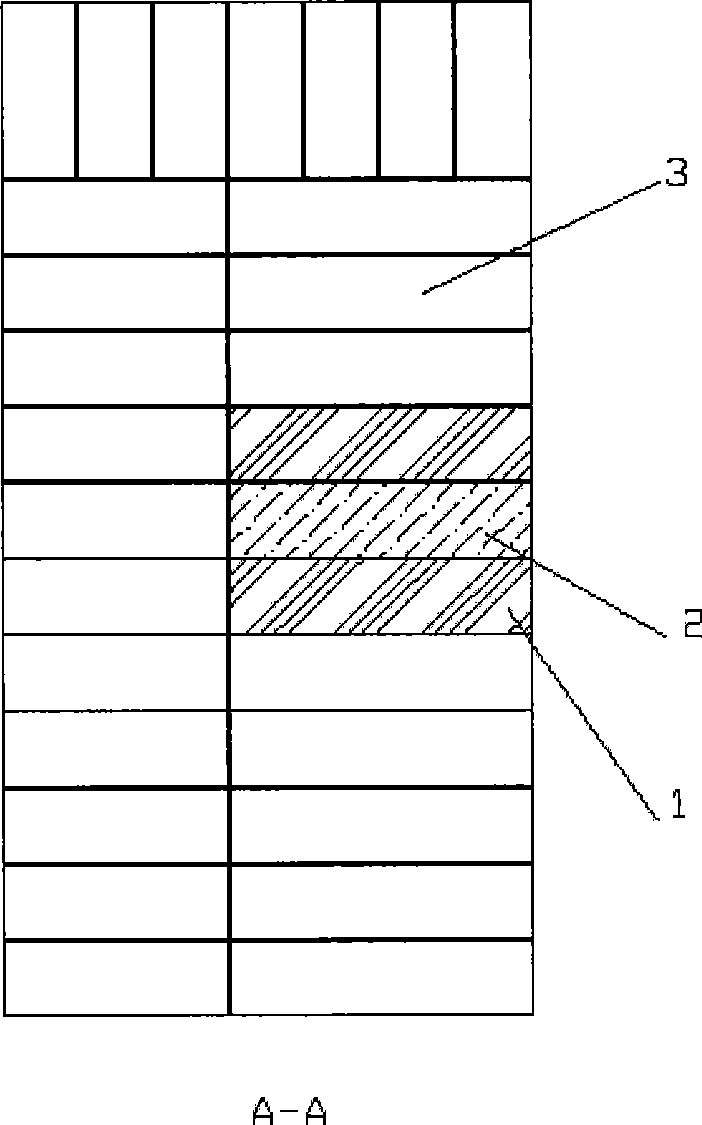

Abrasion resistant steel fiber reinforcement pouring precast block for coke dry quenching oven

A fiber-reinforced, dry-quenched coke oven technology, applied in the field of wear-resistant reinforced pouring prefabricated blocks, can solve the problems of frequent pouring and fast wear rate in the cooling section, reduce downtime for maintenance, improve burst resistance, and reduce maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As we all know, cement as a cementitious material is the main reason for the strength of low-cement castables. The addition amount is less than 4%, the strength is too low, and the wear resistance is not good; the addition amount is higher than 10%, the CaO brought into the cement is too much, and it is easy to form more low-melting feldspar (2CaO·Al2O3· SiO2, MP1590°C), melonite (CaO·Al2O3·2SiO2, MP1550°C). Therefore the cement content of the present invention is 4-10%.

[0023] When there is a water reducer, silica fume, α-Al 2 o 3 The presence of such ultrafine powder can make the castable have high fluidity under low moisture, which has a great influence on the strength and wear resistance of the castable. Silica fume, α-Al 2 o 3 If the addition amount is lower than 3%, the wear resistance is not good; if it is higher than 10%, there is no practical significance for improving the fluidity and strength of the castable. Therefore, silica fume, α-Al of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com