Parallel flow tubes used for heat exchanger and manufacturing method thereof

A technology of parallel flow tubes and heat exchangers, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve problems such as poor welding, cracking of internal ribs, low blasting pressure, etc., and achieve good corrosion resistance, The effect of ensuring surface quality and inner quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

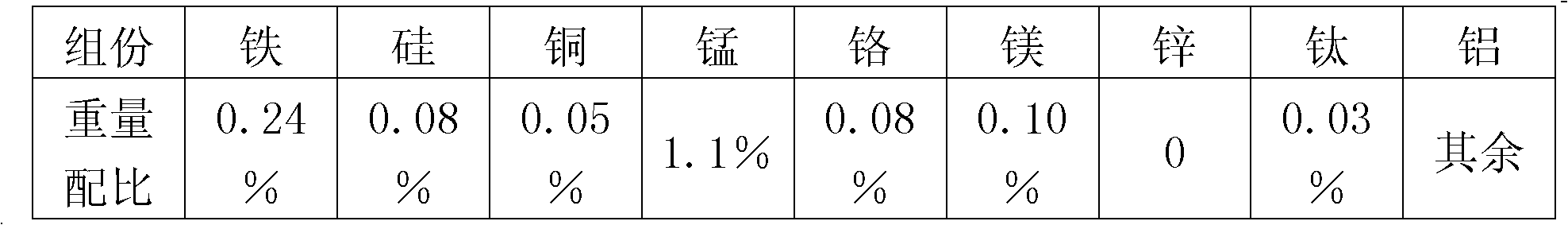

[0021] The chemical composition ratio of the material is:

[0022]

[0023] The method of making parallel flow tubes for heat exchangers is:

[0024] 1) Put the raw materials prepared according to the above weight ratio into the smelting furnace, and adopt the continuous casting and rolling method to produce a tightly wound round aluminum rod coil with a diameter of Φ9.5mm or Φ12.5mm;

[0025] 2) In order to reduce the strength of the round aluminum rod, meet the requirements of continuous extrusion, improve the thermoplasticity of the material, and make the alloy structure and composition more uniform. Put the round aluminum rod coil in the annealing furnace for homogeneous annealing. The annealing temperature is 520 ° C. The round aluminum rod is kept at temperature for 3 hours, then taken out, and cooled to room temperature;

[0026] 3) Straighten the round aluminum rod through the straightening device;

[0027] 4) In order to remove the oil stains, oxide scales and va...

Embodiment 2

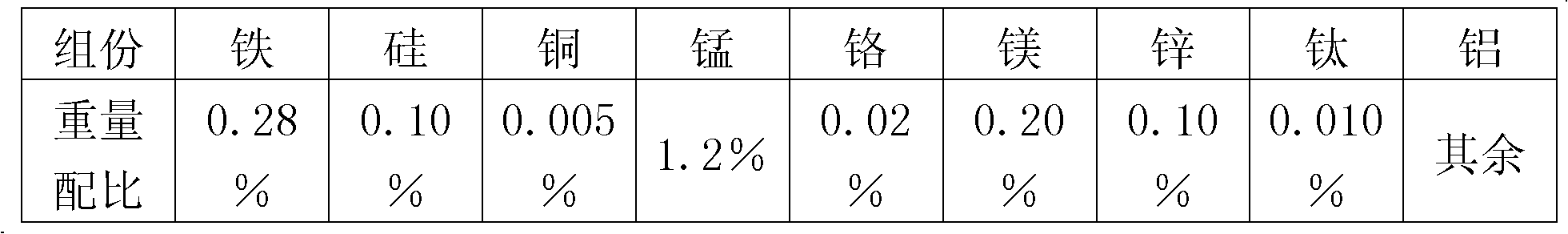

[0032] The chemical composition ratio of the material is:

[0033]

[0034] The method of making parallel flow tubes for heat exchangers is:

[0035] 1) Put the raw materials prepared according to the above weight ratio into the smelting furnace, and adopt the continuous casting and rolling method to produce a tightly wound round aluminum rod coil with a diameter of Φ9.5mm or Φ12.5mm;

[0036] 2) In order to reduce the strength of the round aluminum rod, meet the requirements of continuous extrusion, improve the thermoplasticity of the material, and make the alloy structure and composition more uniform. Put the round aluminum rod coil in the annealing furnace for homogenization annealing, the annealing temperature is 490°C, take out the round aluminum rod after reaching the temperature for 6 hours, and cool to room temperature;

[0037] 3) Straighten the round aluminum rod through the straightening device;

[0038] 4) In order to remove the oil stains, oxide scales and va...

Embodiment 3

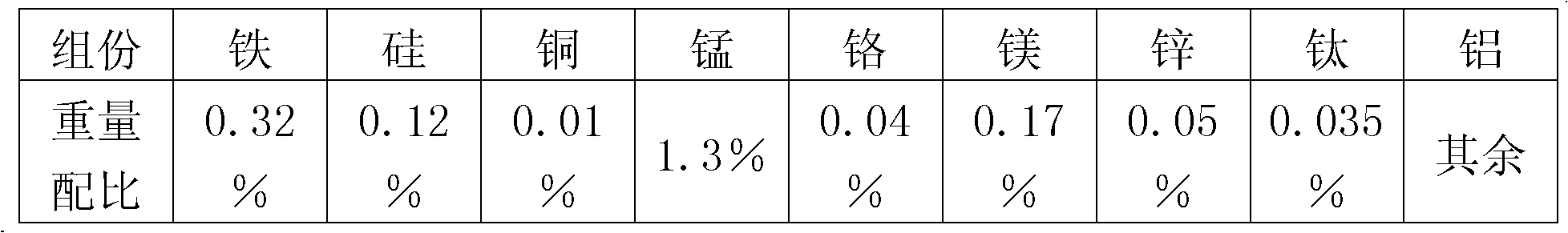

[0043] The chemical composition ratio of the material is:

[0044]

[0045] The method of making parallel flow tubes for heat exchangers is:

[0046] 1) Put the raw materials prepared according to the above weight ratio into the smelting furnace, and adopt the continuous casting and rolling method to produce a tightly wound round aluminum rod coil with a diameter of Φ9.5mm or Φ12.5mm;

[0047] 2) In order to reduce the strength of the round aluminum rod, meet the requirements of continuous extrusion, improve the thermoplasticity of the material, and make the alloy structure and composition more uniform. Put the round aluminum rod coil in the annealing furnace for homogeneous annealing. The annealing temperature is 480 ° C. The round aluminum rod is kept at temperature for 7 hours, then taken out, and cooled to room temperature;

[0048] 3) Straighten the round aluminum rod through the straightening device;

[0049]4) In order to remove the oil stains, oxide scales and var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com