Point source type spaced grouting damage reducing method by roof caving crack expansion filling and directional drilling

A technology of directional drilling and grouting, which is applied in the fields of backfill, earth-moving drilling, safety devices, etc., can solve the problems of unsuitable large-scale promotion and implementation of coal mining enterprises, affecting the production layout of efficient coal mining, and reducing the service life of mines, etc. Achieve the effect of reducing coal transportation efficiency, controlling uneven settlement of overlying rock, and reducing aggregate transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

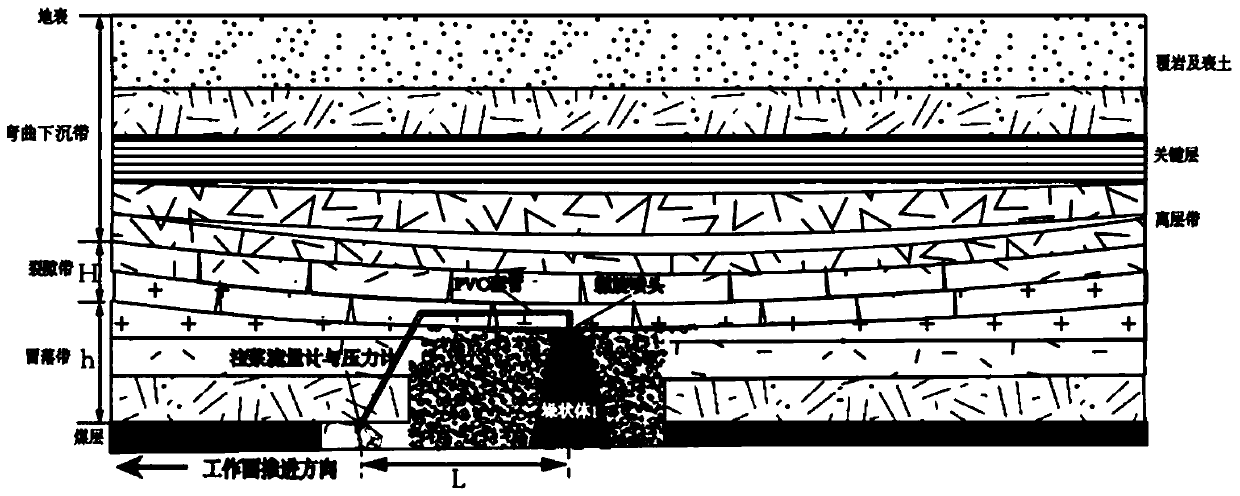

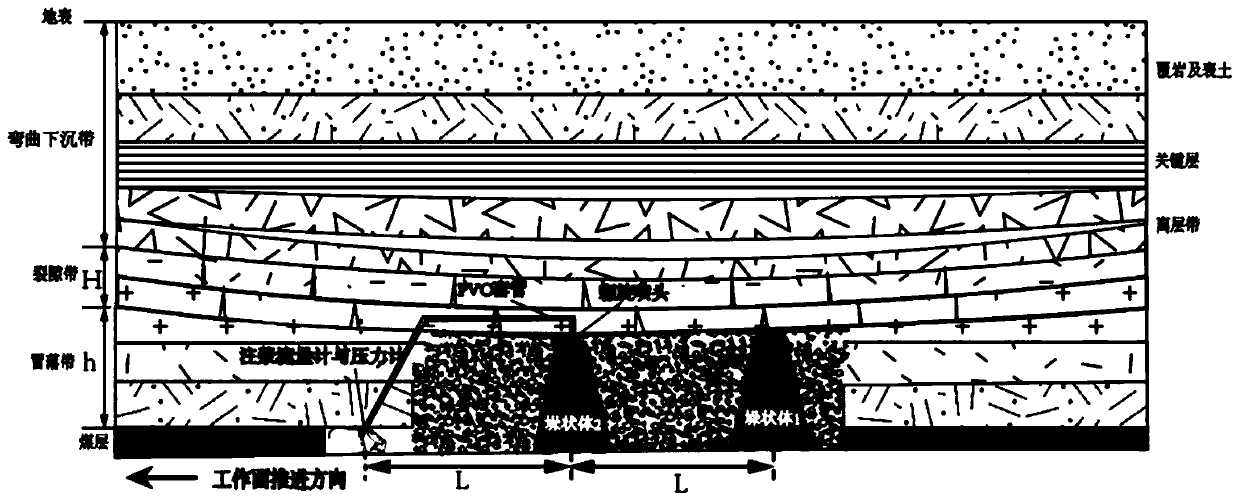

[0034] refer to Figure 1~4 , aiming at the situation that the broken body completely fills (including nearly completely filled) the goaf after the natural collapse of the roof, a method of using the roof collapse to fill and directional drilling point source interval grouting to reduce damage, specifically includes the following steps:

[0035] The first step, due to the complexity of on-site coal mine geological mining, it is necessary to determine the overall height of the caving zone through the empirical relationship between the mining height and the caving zone and the mining geological data of the actual coal mine, and determine the stacking height through the limit caving step of the roof. Pile spacing L, while taking into account a certain safety reserve factor (it is recommended to refer to the relevant specification to take a value of 1.25); the stacking pile spacing L is the calculated value after multiplying the limit span by the safety factor.

[0036] The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com