Construction method of steel latticework column tower crane foundation for underground garage without reserving construction joints

A technology of steel lattice columns and underground garages, which is applied in basic structure engineering, construction, etc., to achieve the effects of saving materials, less earthwork excavation, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

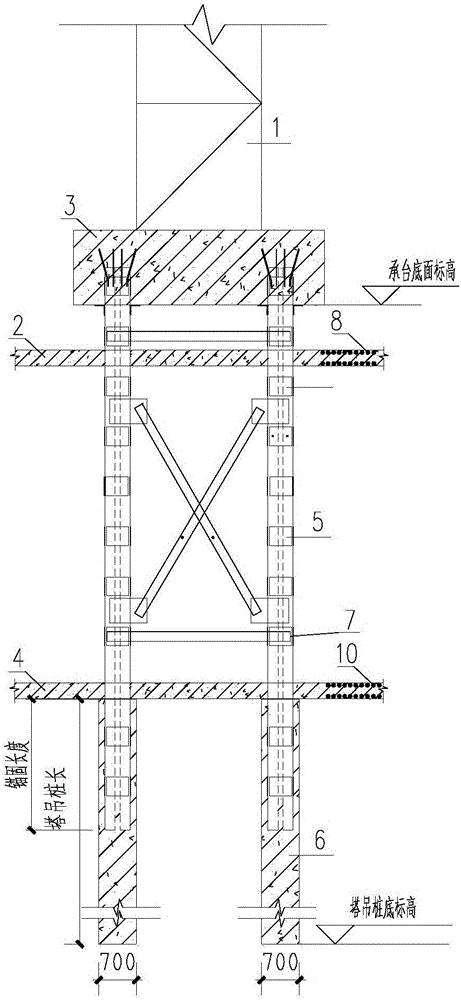

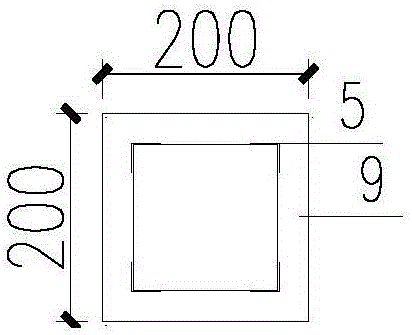

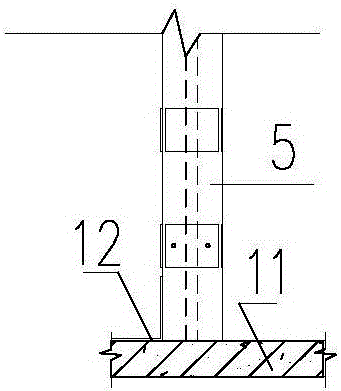

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] refer to Figure 1~Figure 3 As shown, the underground garage of the present invention does not reserve construction joints for the construction method of the steel lattice column tower crane foundation. Excavation → Concrete cleaning on the top of the steel lattice column, welding and anchoring steel bars → Tower crane foundation construction → Tower crane installation → Underground garage floor construction → Underground garage roof construction → Tower crane foundation removal.

[0032] Step S1, determination of the tower crane construction plan: including determination of the position of the tower crane foundation 3 and the determination of the length L of the steel lattice column 5, wherein the position of the tower crane foundation 3 avoids the location of the underground garage foundation, the post-casting belt, and the position of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com