Assembly type concrete stairwell external wall structure and construction method thereof

A stairwell and concrete technology, applied in the direction of building structure, walls, building components, etc., can solve the problems of large torsion effect, difficult construction, poor stability of wall limbs, etc., and achieve the effect of low cost, convenient construction and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

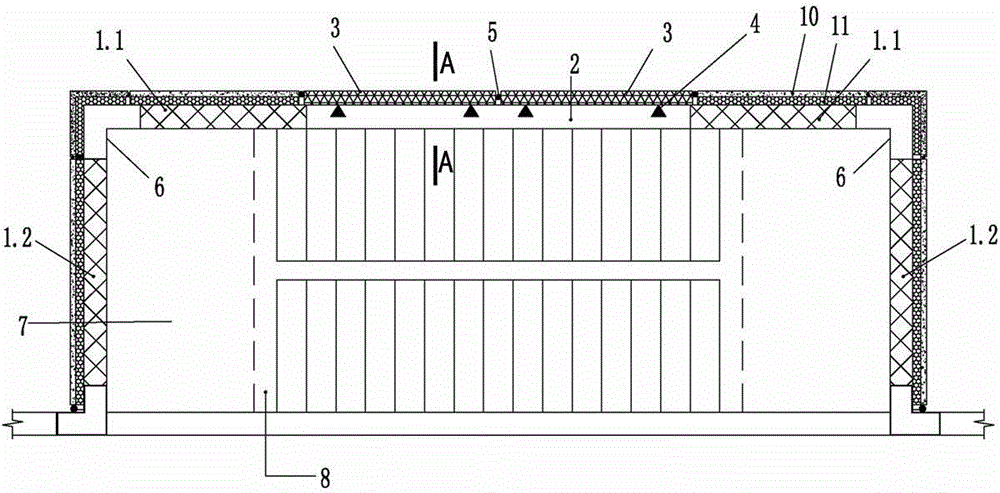

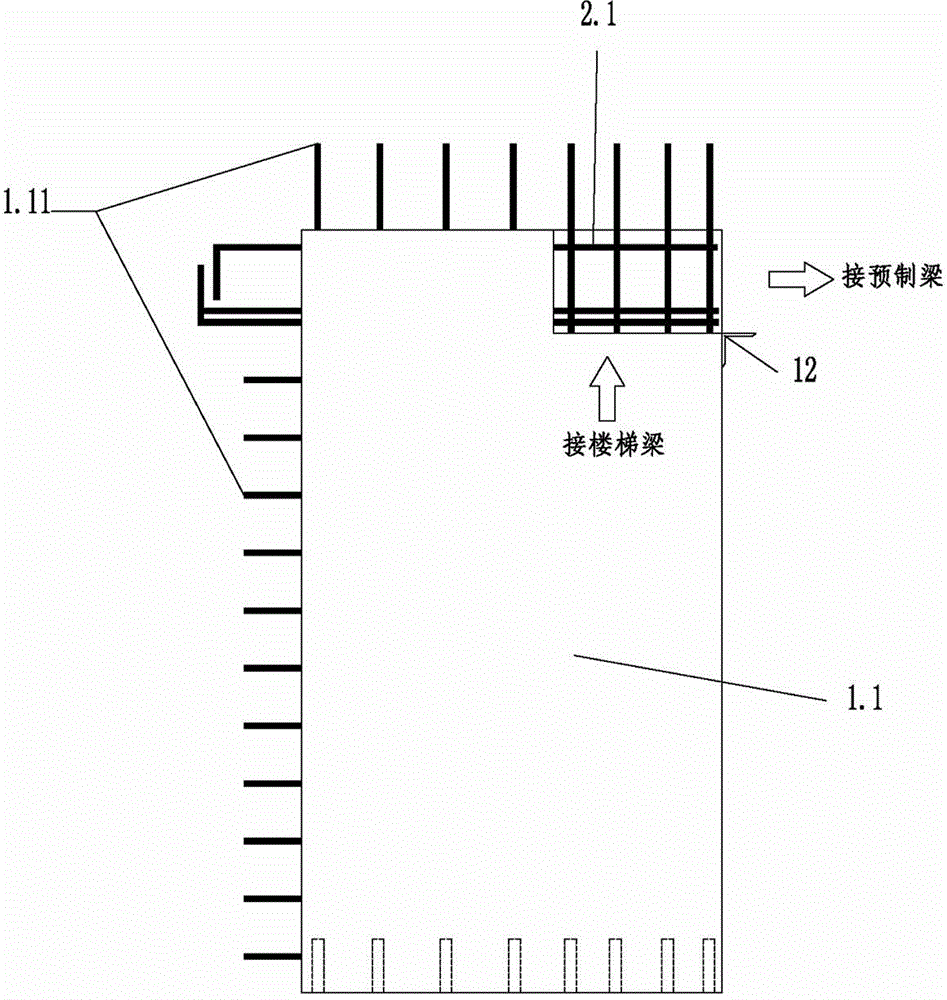

[0032] A prefabricated assembled concrete stairwell exterior wall assembly structure designed by the present invention, its schematic diagram is as follows figure 1 , image 3 , Figure 4 and Figure 5 shown. Including prefabricated load-bearing longitudinal shear wall panels 1.1, prefabricated load-bearing transverse shear wall panels 1.2, prefabricated beams 2, non-load-bearing external wall panels 3 and hanging panel connectors 4, the prefabricated load-bearing longitudinal shear force Wall panels 1.1 and prefabricated load-bearing transverse shear wall panels 1.2, the prefabricated beam 2 and non-load-bearing external wall panels 3 are used on the outer part of the tread plate 8 (the horizontal joints of the upper and lower non-load-bearing external wall panels 3 are located at the prefabricated beam 2 The upper edge of the upper edge of the left and right non-load-bearing external wall panels is located in the middle of the prefabricated beam 2); the prefabricated load...

Embodiment 2

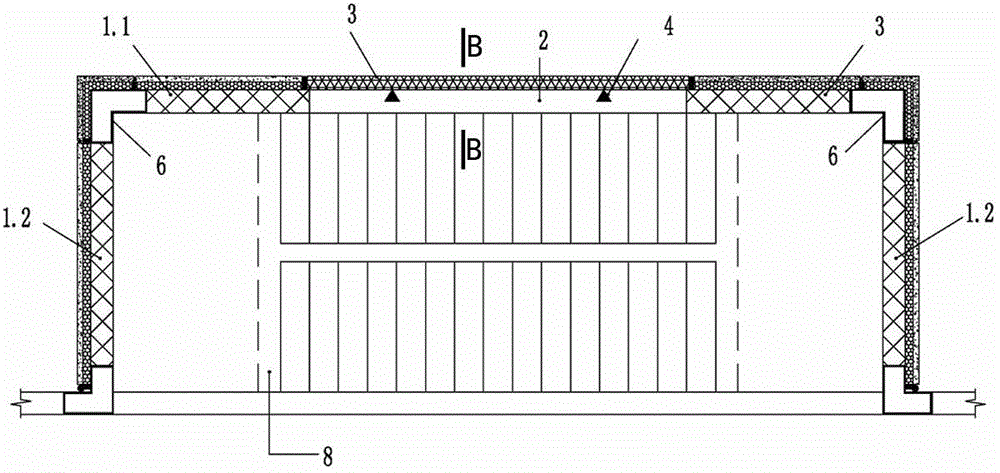

[0038] like figure 2 , Image 6 As shown, the structure and construction method of the prefabricated concrete stairwell exterior wall assembly structure are similar to those of Embodiment 1, the main difference is: the prefabricated beam 2 and the non-load-bearing external wall panel 3 on the outer part of the tread plate 8, and the upper and lower two non- The horizontal seam of the load-bearing external wall panel 3 is located in the middle of the beam body of the prefabricated beam 2 . So no more details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com