Hollow pipe member for in-situ deposited steel bar reinforced concrete combined structure

A combined structure and hollow tube technology, applied in building components, building structures, floor slabs, etc., can solve problems such as poor shear and torsion resistance, large deflection and deformation, and inability to form well-shaped rib two-way slabs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

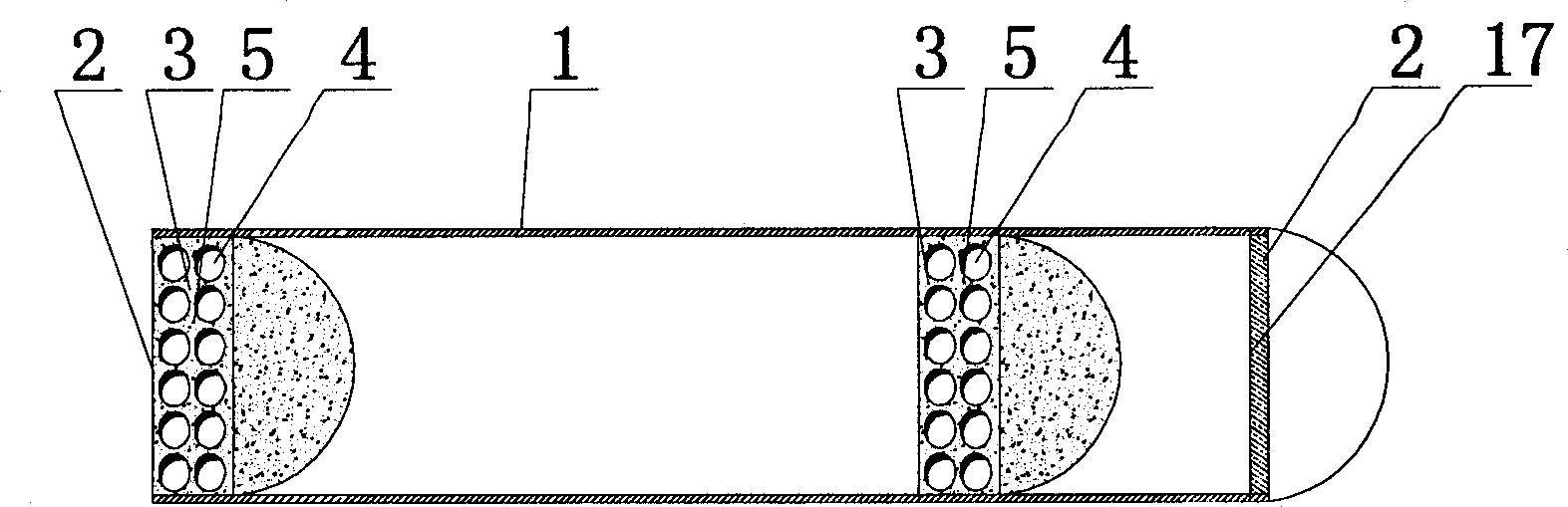

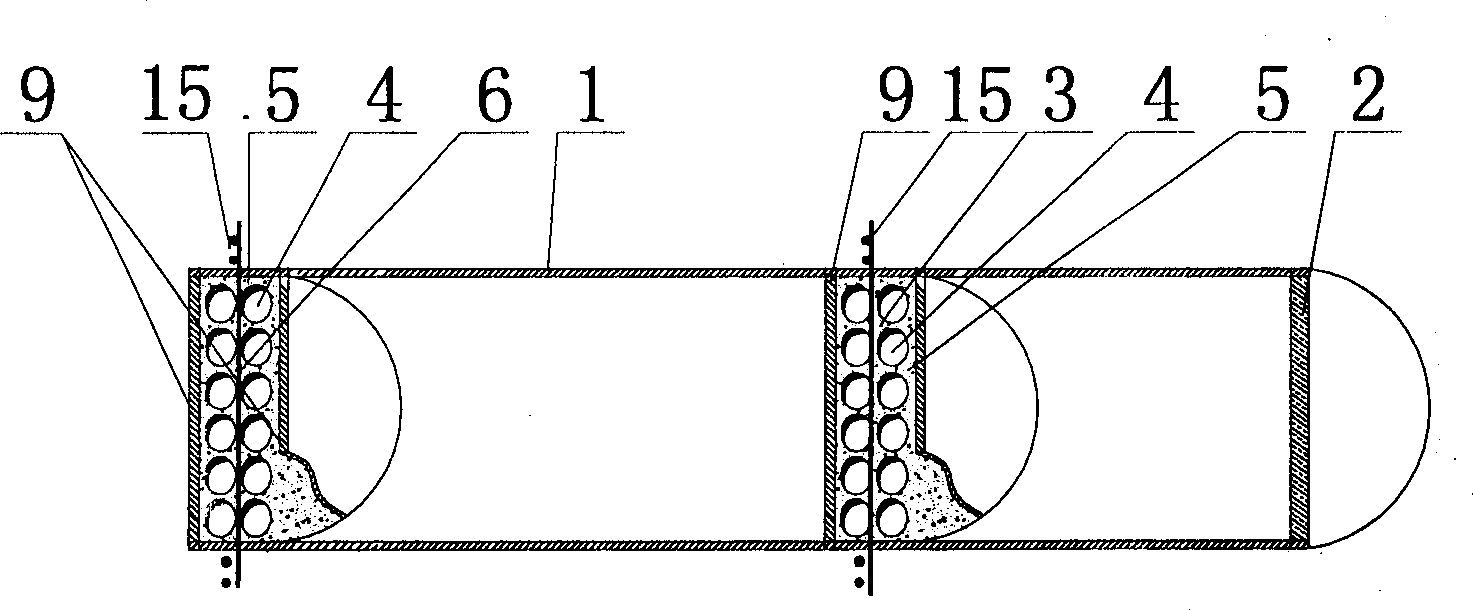

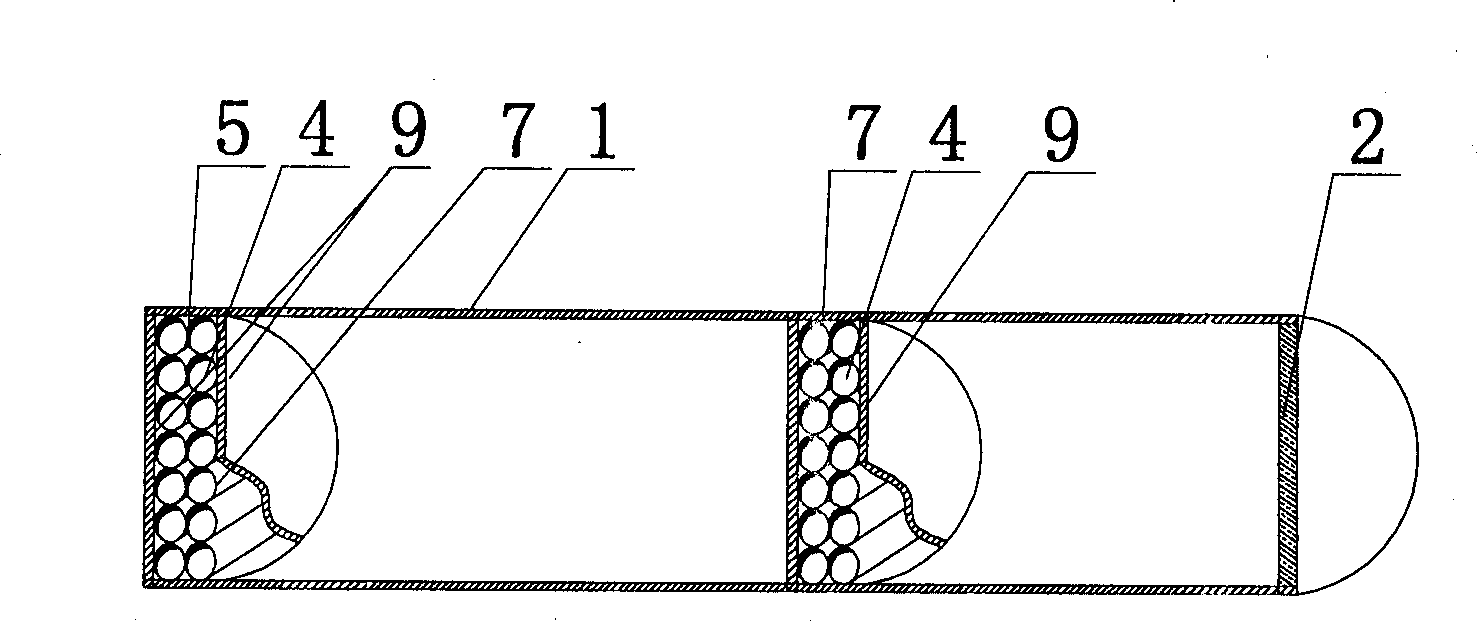

[0034] The invention is attached figure 1 As shown, it is composed of a hollow tube (1), a head (2) at both ends of the hollow tube (1), and a transverse stiffener (3) arranged in the hollow tube (1). The hollow tube (1), the head (2) ), the cross-sectional shape of the transverse stiffener (3) is circular, square, trapezoidal or other shapes, and it is characterized in that the transverse stiffener (3) is a hollow transverse stiffener (3), which consists of a hollow hole (4) It is composed of a hole wall member (5) forming a hollow hole (4), and the hollow hole (4) is located in the hole wall member (5). Since the transverse stiffener (3) in the hollow tube (1) is a hollow transverse stiffener (3), this component has the characteristics of light weight and low cost. The defects of components and crack-resistant structure also have the characteristics of high strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com