External prestressing corrugated steel web T-shaped beam and construction method

A corrugated steel web and external prestressing technology, which is applied to bridges, bridge parts, bridge materials, etc., to achieve good economic performance, reduced consumption, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

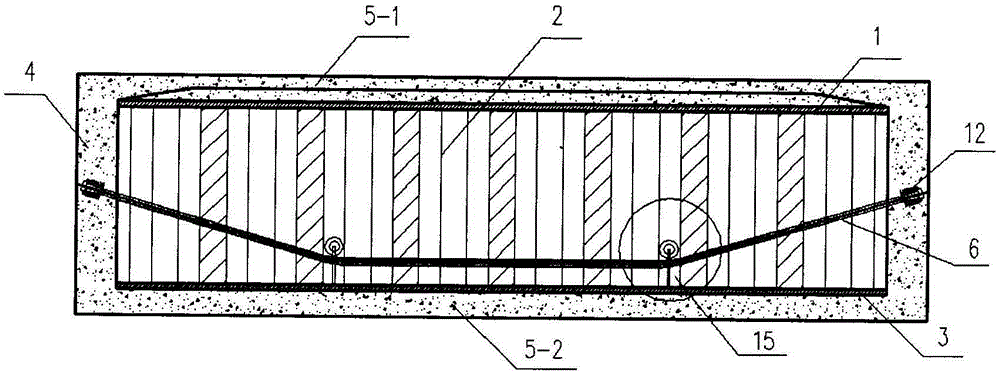

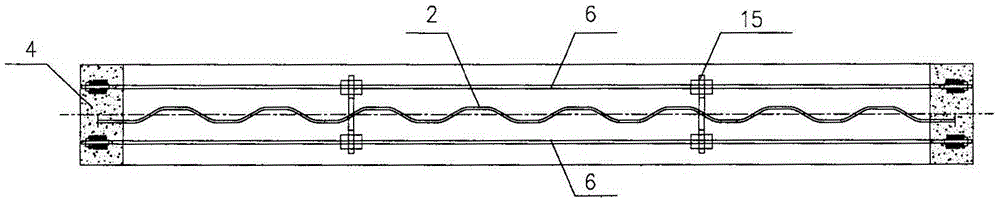

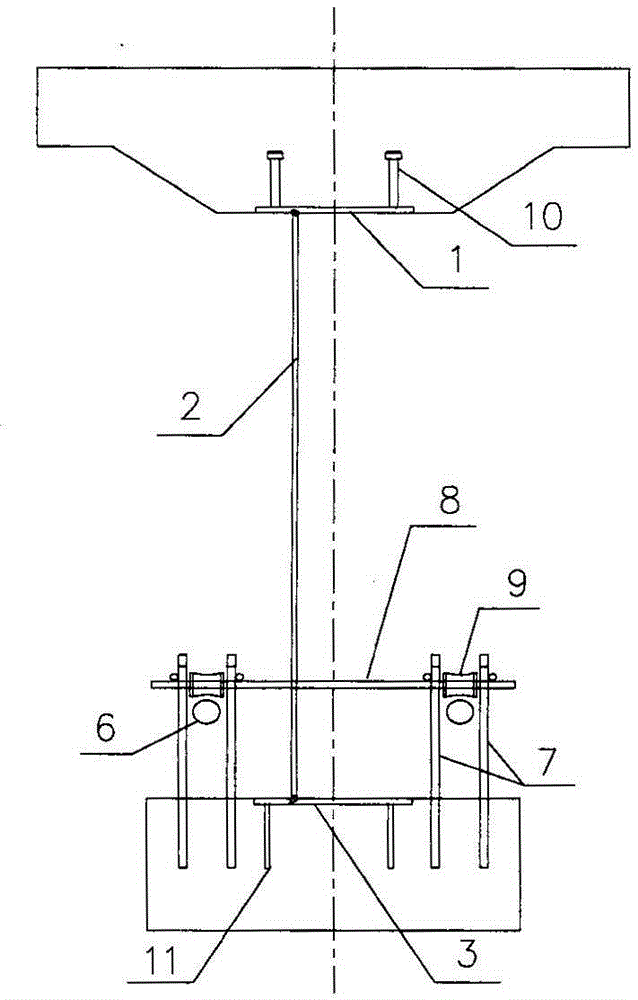

[0034] Such as Figure 1-3 As shown, the externally prestressed corrugated steel web composite T beam described in this embodiment, the T beam is a prefabricated T-shaped section beam, including a concrete top plate 5-1, a concrete bottom plate 5-2, an end beam 4, a corrugated Steel web 2, external prestressed cable 6 and steering device 15. The concrete top slab 5-1 and the concrete bottom slab 5-2 are respectively connected to both ends of the corrugated steel web 2 through shear connectors to form a T-shaped cross-section beam. Among them: the shear connectors provided on the lower edge of the concrete roof 5-1 to resist horizontal shear force include upper flange steel plates 1 and studs 10; the shear connectors provided on the upper edge of the concrete bottom plate 5-2 include lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com