Manufacturing method for regular hexagonal honeycomb latticed steel hollow floor frame box type structure

A technology of regular hexagonal and hollow floors, which can be applied to building structures, floor slabs, building components, etc., and can solve the problems that the unit occupies too large an area and cannot be loaded and transported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

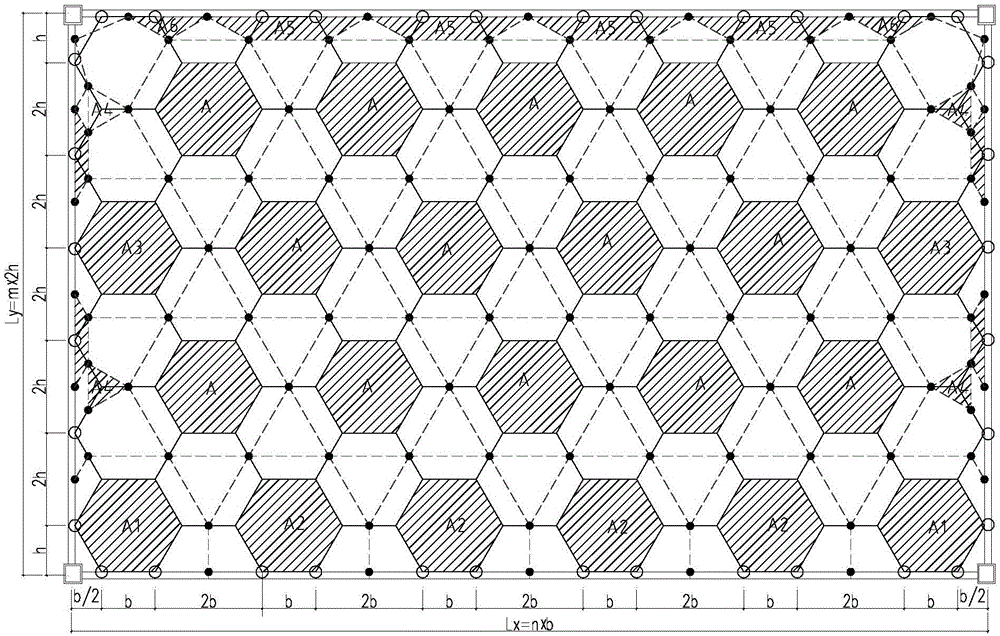

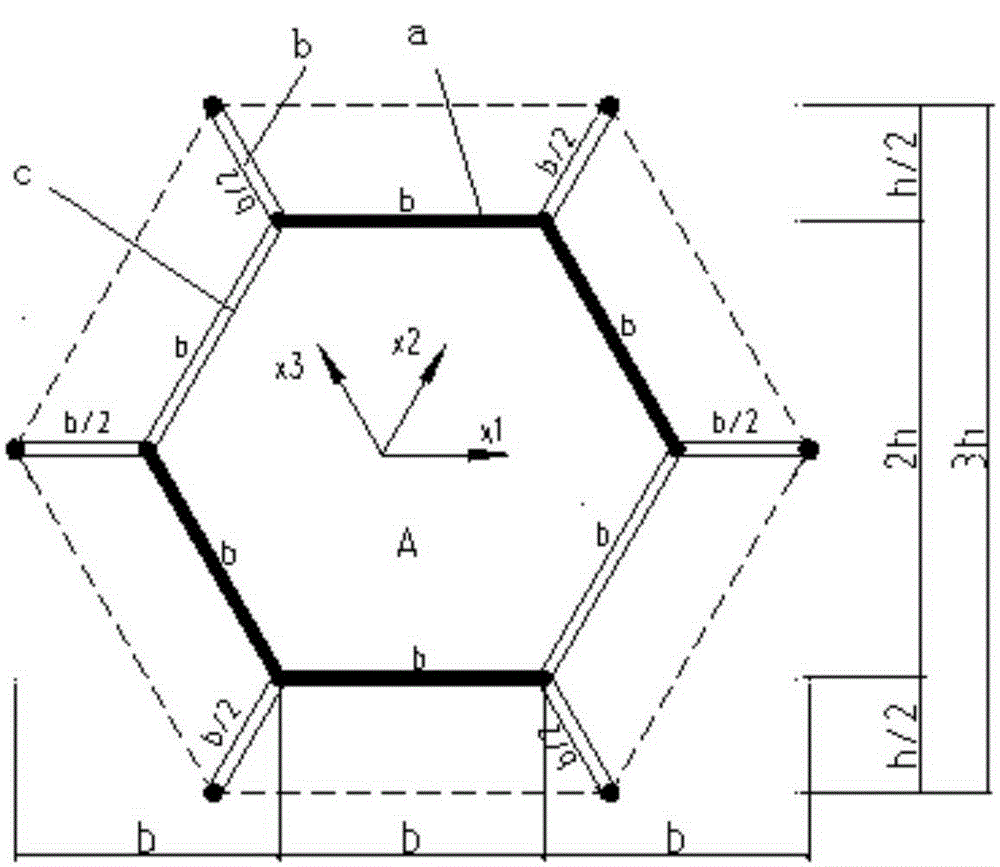

[0015] figure 1 It is the plan view of the floor structure of a multi-storey public building. When the height of the regular hexagon is 2h=2×2m=4m, its span L y =6×2h=24m, the column network on the long side is arranged alternately with b and 2b, L x =17b=17×2m / sin60°=17×2.31m=39.27m, the floor area of each floor is 943m 2 , the total area of the four-story hall is 3770m 2 (Stairs, elevators, and fire protection area are not included in the lobby), and the structure of the entire lobby building is "multi-layer (4 floors) large-span (L=24m) assembled integral space steel grid box structure".

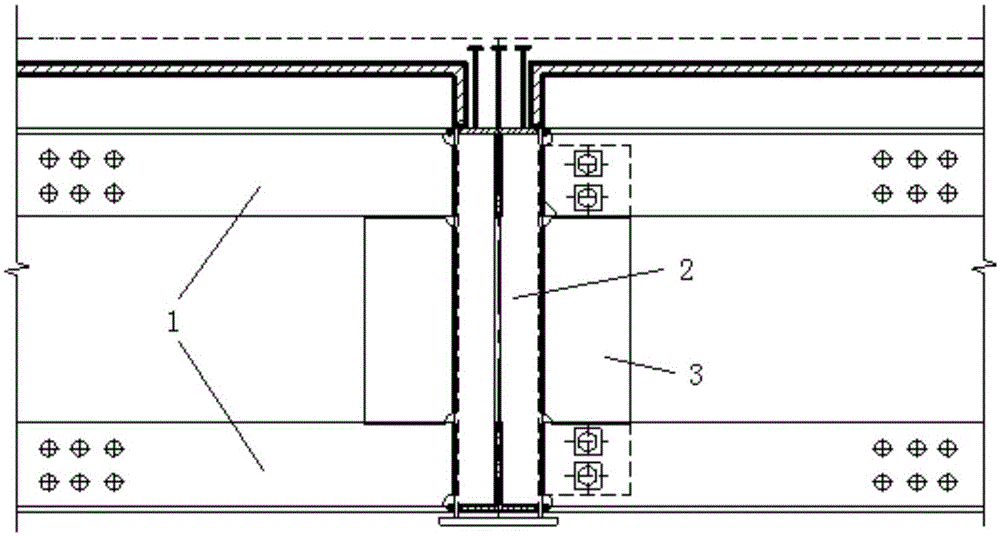

[0016] The specific construction and installation method is carried out as follows:

[0017] Step 1: Press figure 1 Plane and level the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com