Closed-loop type mine-used lifesaving cabin body

A rescue cabin, closed-loop technology, applied in the field of mine rescue cabin structure, can solve problems such as poor anti-knock ability, inconvenient underground transportation, and affecting installation accuracy, so as to avoid stress concentration, facilitate construction and transportation, and improve explosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

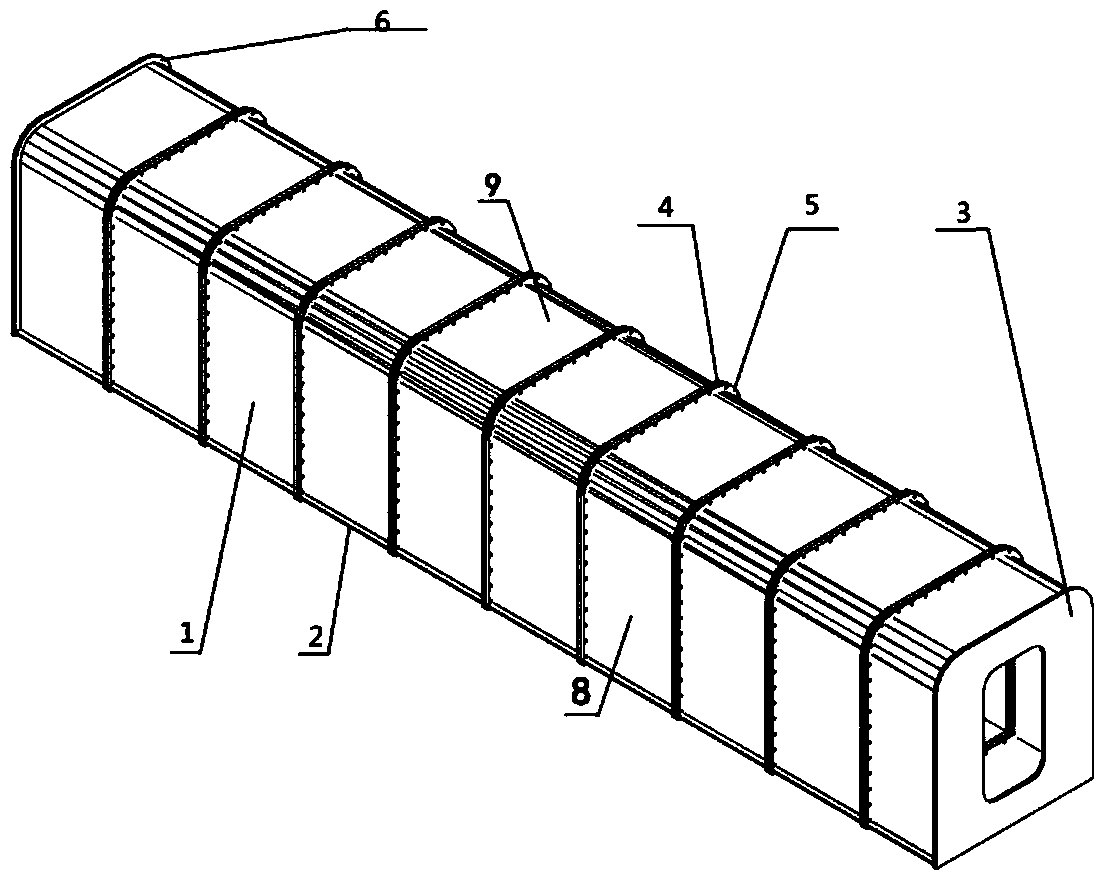

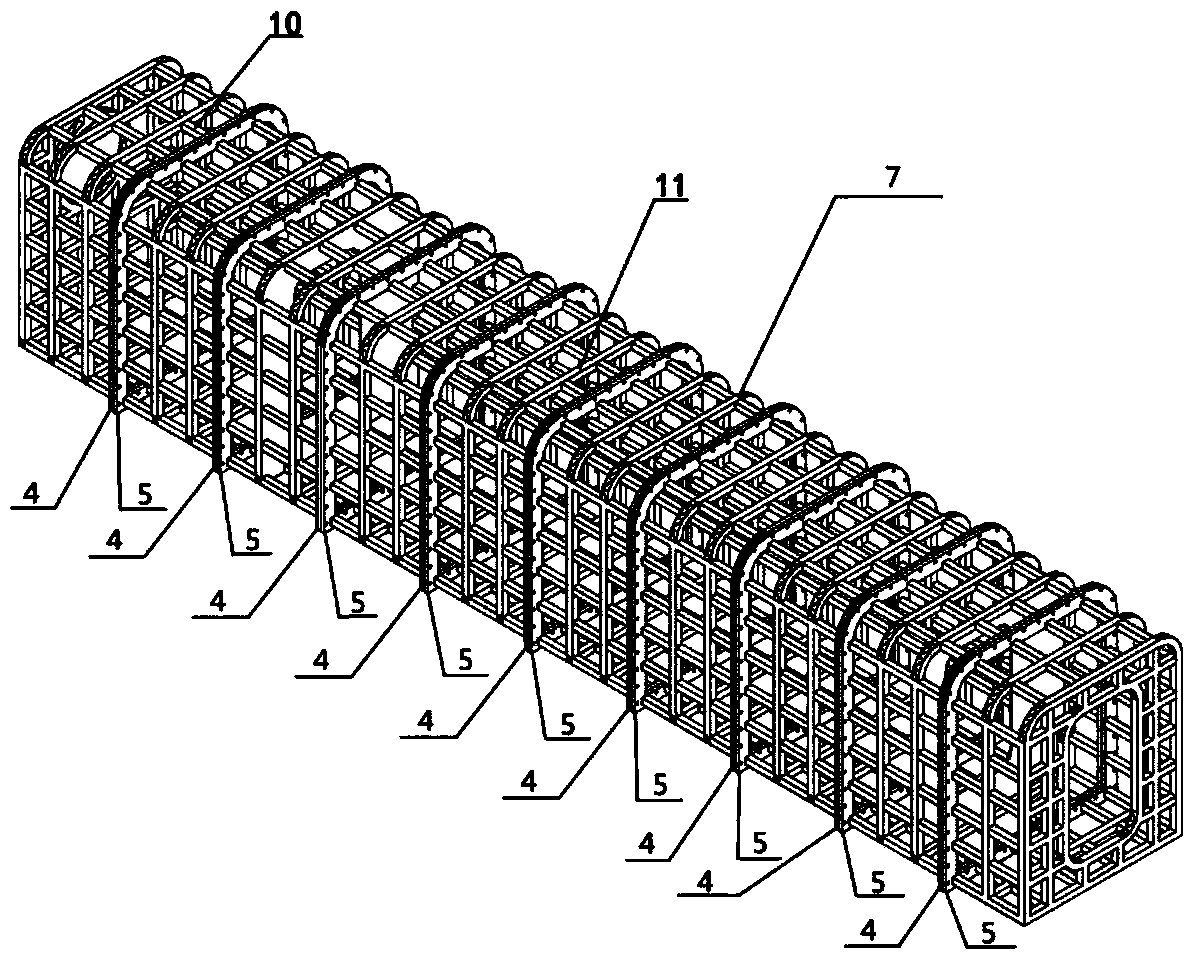

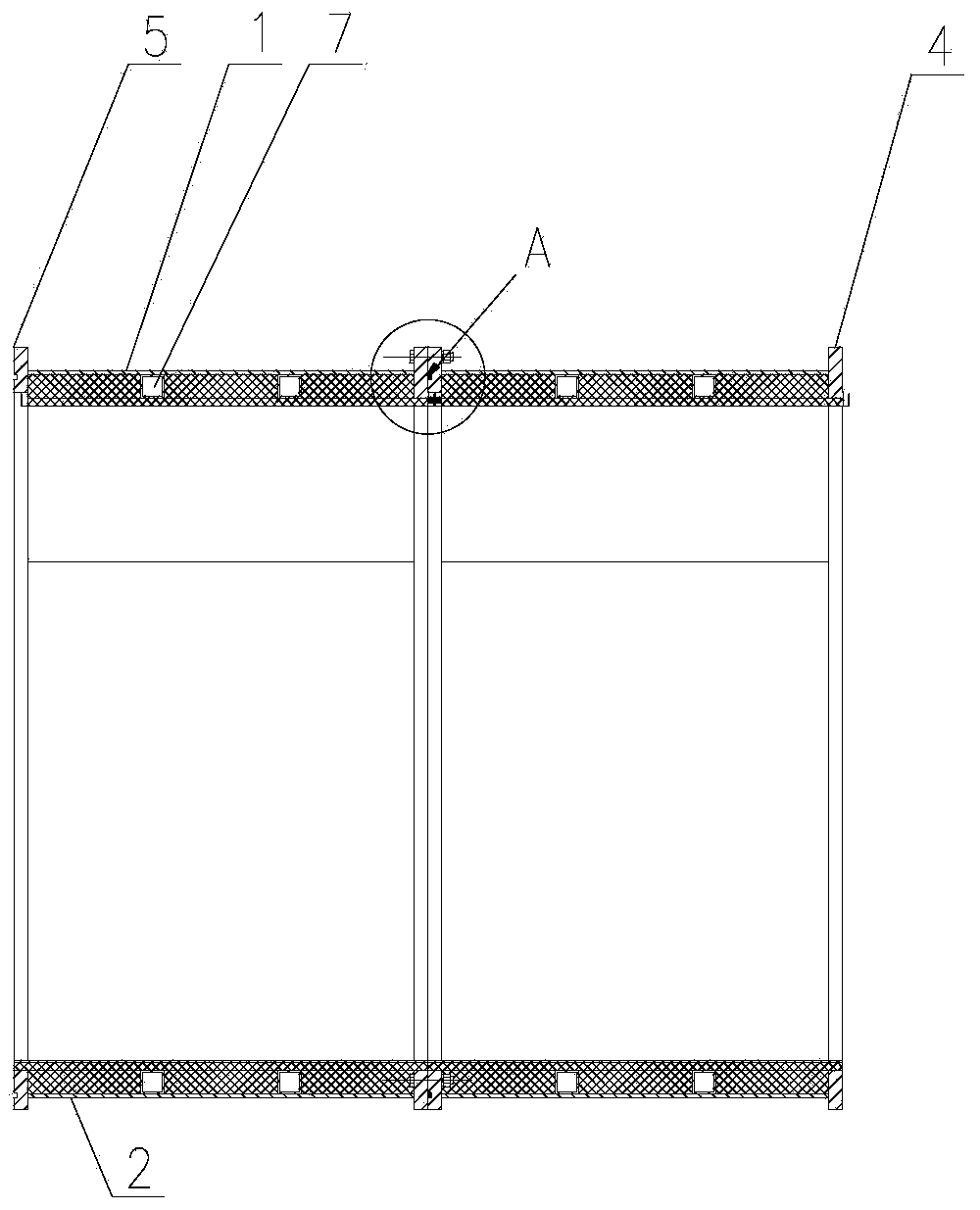

[0015] As shown in the figure: the closed-loop mining rescue cabin cabin body 9 is composed of a plurality of cabin body units 8 connected end to end, and each cabin body unit includes an inverted U-shaped cabin body shell 1 and a cabin body that cooperates with the cabin body shell 1 The bottom shell 2 is provided with an isolation bulkhead 3 and an escape bulkhead 6 at the two ends of the rescue cabin body 9, and the two ends of the cabin unit 8 are respectively provided with a cabin connecting flange I4 and a cabin connecting flange II5. The cabin body unit 8 is fixedly connected by the cooperation of the cabin body connection flange I4 and the cabin body connection flange II5; the inside of the rescue cabin cabin body 9 is provided with a transverse reinforcing rib 10 parallel to the cabin shell shell 1 and connected with the cabin body. Lan I4 is parallel to the annular ribs 11, and the transverse ribs 10 and the annular ribs 11 are staggered to form a closed-loop rib grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com