Truss sheet unit of steel truss girder, steel truss girder structure and mounting method thereof

An installation method and technology of steel truss girders, which are applied to bridges, truss bridges, bridge materials, etc., can solve problems such as the influence of bridge alignment and internal force distribution, the large number of high-strength bolt connections, and the difficulty in controlling the quality of welds, etc., to achieve reduction Splicing work, improving the quality of ex-factory products, and reducing the number of splicing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further described below in conjunction with the accompanying drawings.

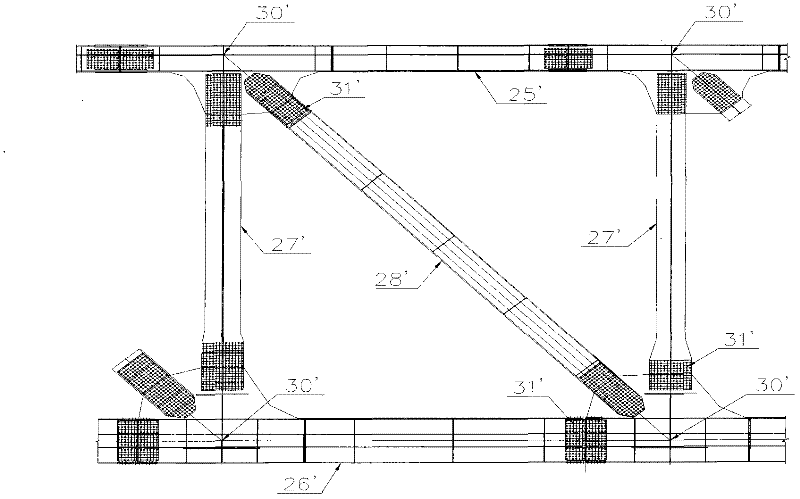

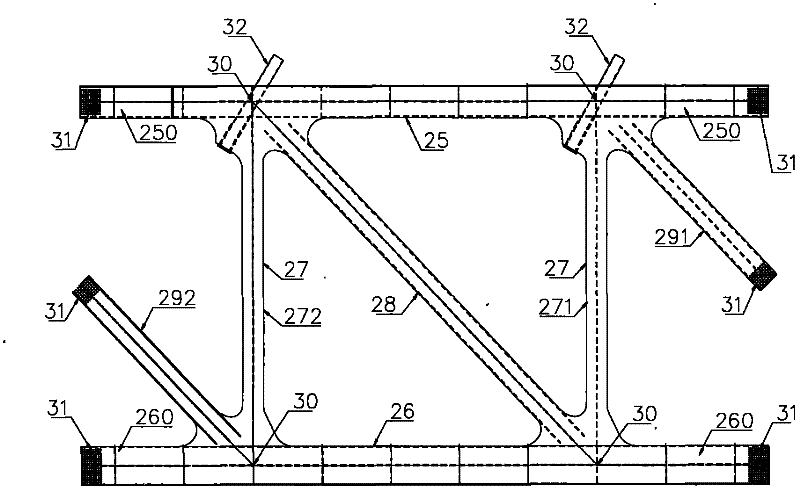

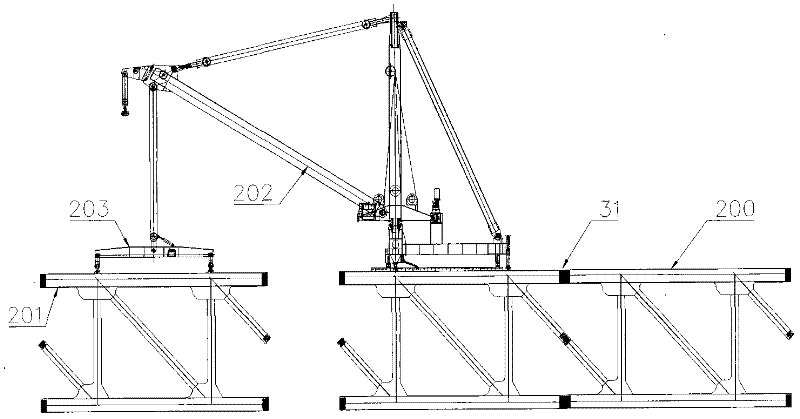

[0036] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a steel truss girder unit of a steel truss structure in the present invention, and the steel truss girder unit includes an upper chord 25 and a lower chord 26 . The upper chord 25 and the lower chord 26 have the same length, and the upper chord 25 and the lower chord 26 are arranged horizontally and parallel to each other. Two vertically arranged webs 27, the two ends of the two webs 27 are welded to the upper chord 25 and the lower chord 26 to form a rectangular frame, the two ends of the upper chord 25 and the lower chord 26 are further extended to form the upper connecting rod 250 and the lower chord. connecting rod 260 . The steel truss girder truss unit is also provided with a diagonal rod 28, which connects two opposite corners of the above-mentioned rectangular frame body. The two w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com