Light type adjusting machine

A technology for adjusting the machine and light sensing probe, applied in the direction of testing optical performance, etc., can solve the problems of meeting the requirements, unable to guarantee the light type of the lampshade, low detection efficiency, etc., to achieve the effect of low cost, improved product quality, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

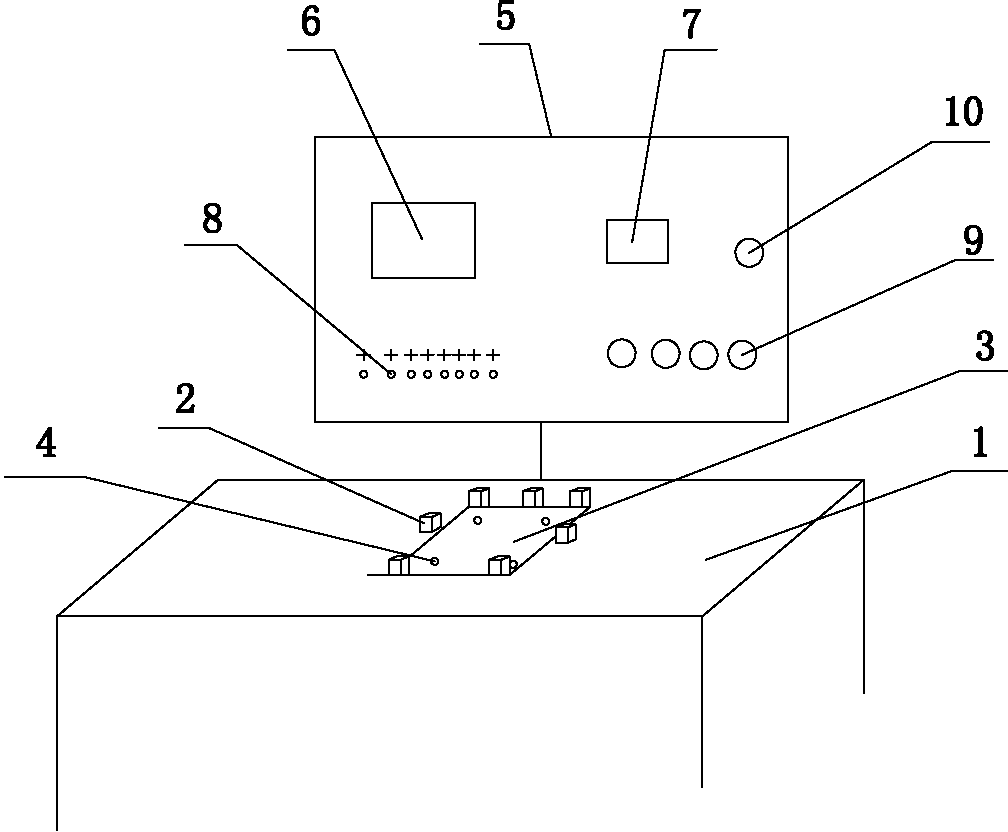

[0012] Such as figure 1 As shown, the present invention includes workbench 1, and lampshade clamp 2 is installed on workbench 1, is used for fixing automobile lampshade, and different lampshades of automobiles can select different lampshade fixtures for use. A glass cover 3 is arranged below the lampshade fixture 2 , and the lampshade fixture 2 is located around the glass cover 3 . A photosensitive probe 4 is arranged under the glass cover 3 , and the photosensitive probe 4 is connected to the instrument display device 5 on the side of the workbench 1 . The meter display device 5 is provided with a display screen 6 , a touch operation screen 7 , multiple sets of electrodes 8 and voltage adjustment buttons 9 for adjusting the voltage of the multiple sets of electrodes 8 . The photosensitive probe 4 feeds back to the display screen 6 after measuring the data. The instrumen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com