[0003] The track slab laid on the roadbed has been subjected to the pressure from the two steel rails for a long time, and the track slab is often cracked or broken due to external force deformation, thus causing unnecessary losses. At the same time, it is very difficult to maintain. Convenience; for this reason, in the manufacturing process of track slabs, steel bars or steel strands or steel rods or steel wires are often set in the track slabs and prestressed to reduce the deformation of the track slabs caused by external forces; The prestressing method of the track slab can be applied by the pre-tensioning method and the post-tensioning method. In practical applications, most of the existing track slabs are prestressed and post-tensioned concrete track slabs. The manufacturing process of prestressed and post-tensioned concrete track slabs is very complicated. The efficiency is low, and a large number of anchors are required to anchor the prestressed tendons, and the existing track slabs usually have steel cages to enhance the strength of the track slab, which greatly increases the cost of the track slab

[0004] In addition, the

track circuit used in the

railway signal system uses the rail as the

transmission medium to transmit information about the idleness or occupancy of the section, as well as various information to control the operation of the

train; the

transmission performance of the

track circuit is affected by

line resistance,

inductance, and the type of

ballast bed. Influenced by many factors such as cleanliness and cleanliness, the limit length of the

track circuit varies greatly under different line conditions; the slab track test section of the Qinshen Passenger

Dedicated Line mainly draws on Japan’s experience and adopts two-way post-tensioned prestressed track slabs. Due to the post-tensioning process, in addition to the prestressed steel strands in the track slab, it is also necessary to configure ordinary steel cages to meet the strength of the track slab itself; the common steel cages for common post-tensioned prestressed track slabs , and the lower two

layers of steel mesh. Each layer of steel mesh is composed of 20 F10 steel bars in the longitudinal direction and 30 F10 steel bars in the horizontal direction. The total

mass of ordinary steel bars is 291kg. , forming many closed figures in geometric shape; when the track circuit is working, the alternating

signal in the

audio frequency range is transmitted in the rail, and when the current in the rail changes, an alternating

magnetic field is generated around the rail, which is passed through

electromagnetic induction in the rear A number of alternating induced currents are generated in the steel mesh in the tensioned track slab, and the alternating

magnetic field generated by these induced currents will in turn prevent the change of the current in the rail; due to the generation of the induced current, the

electric power transmitted by the track circuit is affected. The loss is caused, which leads to the shortening of the limit length of the track circuit; when the

steel bar in the track slab is closer to the rail, the induced current formed in the steel mesh of the track slab is stronger, and the

energy loss transmitted by the track circuit is more serious, and the limit length of the track circuit On the contrary, when the steel mesh in the track slab is farther away from the rail, the induced current formed in the steel mesh of the track slab is weaker, the

energy loss of the track circuit transmission is less, and the limit length of the track circuit is longer; French experts require that steel bars can only be buried in the area below 40cm below the rail surface, in order to reduce the induced current generated in the track slab steel mesh to a

small range, so that the electrical

transmission function of the track circuit will not be affected too much, but There is no quantitative analysis of the data of 40cm; it is very difficult to realize that the track plate is more than 40cm away from the track surface, and the entire track structure will be completely changed

[0005] Based on the above reasons, researchers have been making unremitting efforts to study and constantly looking for new and practical methods to solve the problems of complex manufacturing process, high cost and unsatisfactory track circuit of concrete track slabs.

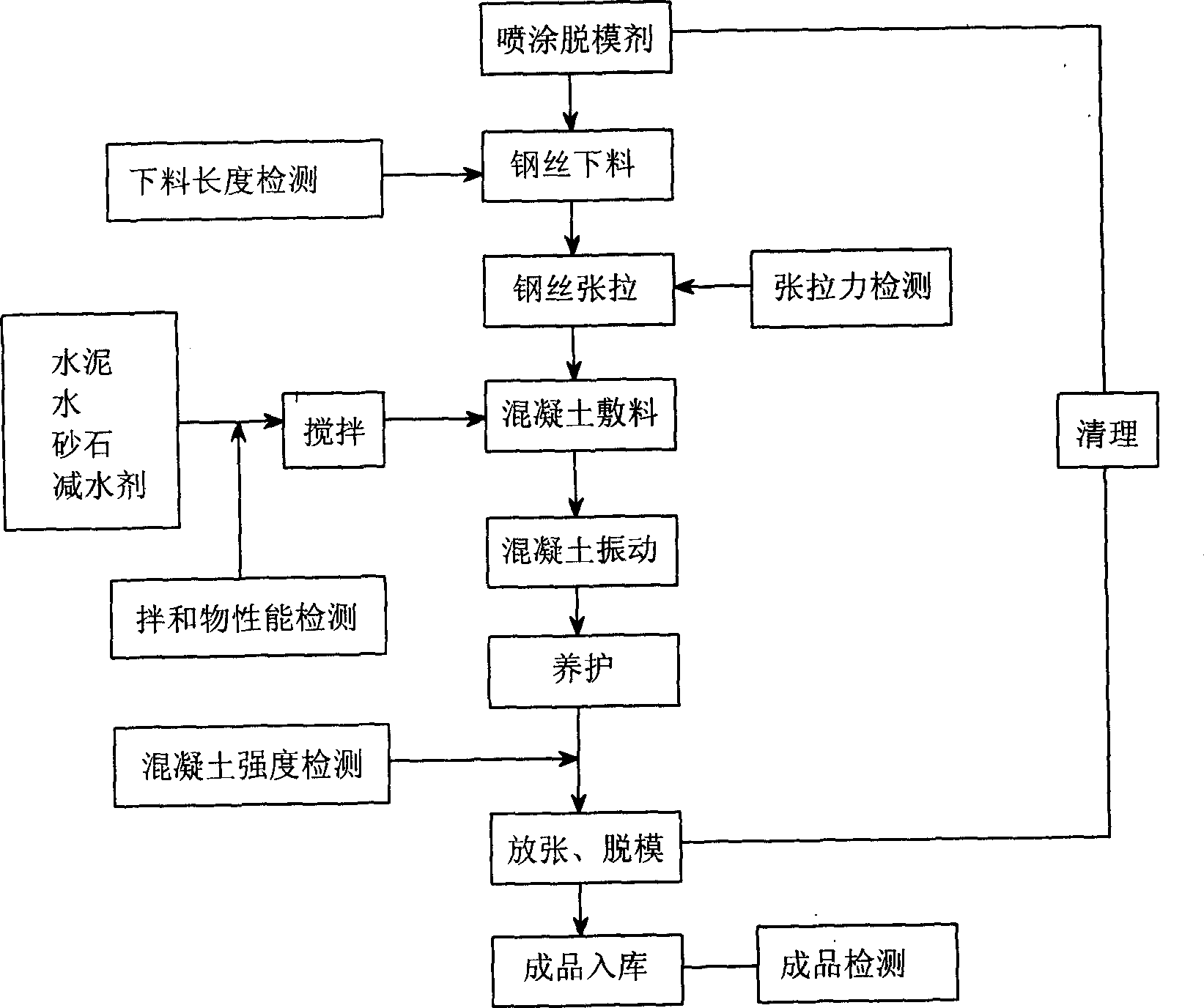

[0006] In order to solve the problem of the production process of concrete track slabs, on the basis of in-depth research and absorption, the researchers found that the post-tensioning method has many production processes, low production efficiency, and consumes a large amount of anchors, high cost and low product quality. It is not easy to guarantee and is not suitable for large-scale application; compared with the post-tensioning method, the production process of the pre-tensioning method is simple and the mechanical properties of the components are excellent, especially the cost of the components is greatly reduced; therefore, the production of prestressed two-way pre-tensioned concrete track slabs saves cost, simplify the process, and the mechanical properties of the components are excellent, and the loss of the track circuit is small. Because of this, in order to solve the problem of

mass production of two-way pretensioned concrete track slabs, researchers continue to improve the existing production process, and actively test, gradually Enabling the production of two-way pretensioned concrete track slabs

[0007] At present, the process suitable for the

mass production of track slabs is mainly the long-line pedestal production process, but it is not difficult to find in practice that the long-line pedestal production process cannot perform two-way

discharge Zhang) can only produce prestressed post-tensioned concrete track slabs or prestressed unidirectional pre-tensioned concrete track slabs, but cannot produce prestressed two-way pre-tensioned concrete track slabs; as far as the developed countries of high-speed railways in the world are concerned, Japan The track slabs in China use two-way unbonded post-tensioned concrete track slabs. The Italian track slabs use longitudinal pre-tensioned and transverse post-tensioned concrete track slabs. my country’s Qinshen Passenger

Dedicated Line uses two-way post-tensioned concrete track slabs based on Japan’s experience. Concrete track slabs by tensioning fixed pedestal method, so far, there is no precedent for mass production of two-way pre-tensioned concrete track slabs in developed countries of high-speed railways, and there is no

record in relevant literature.

Login to View More

Login to View More  Login to View More

Login to View More