Curable composition

A composition and curing technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy surface injury, low hardness, appearance damage, etc., and achieve excellent flexibility and curl resistance, high hardness, and easy handling. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

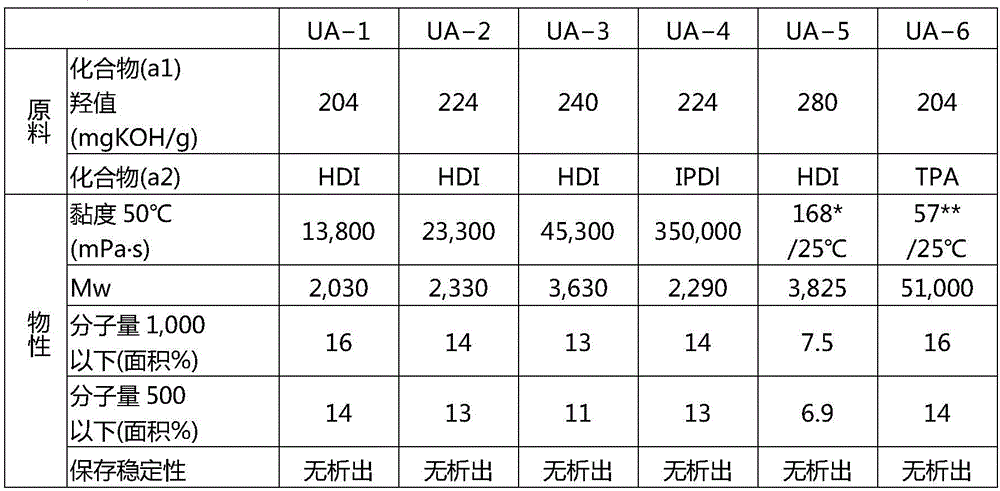

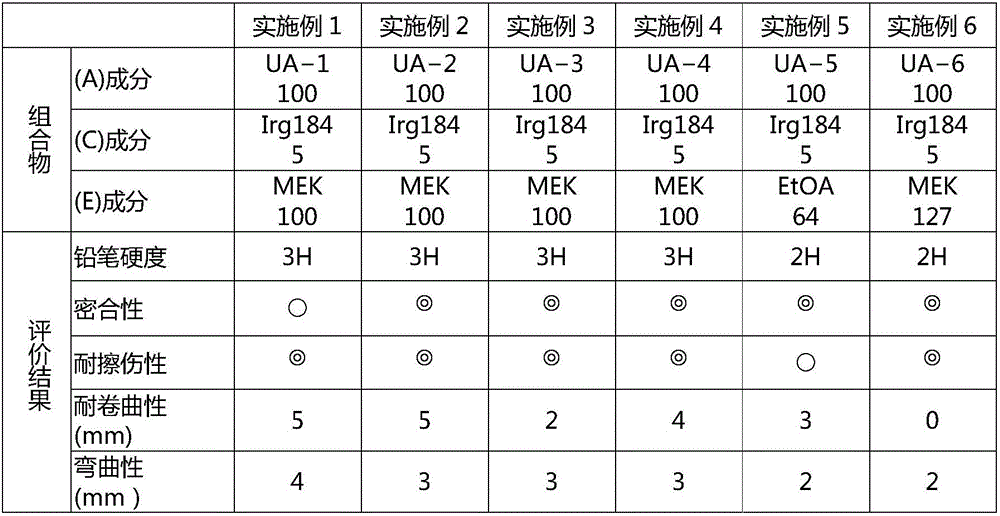

[0230] Examples and comparative examples are shown below, and the present invention will be described more specifically. Furthermore, the present invention is not limited to these examples.

[0231] In addition, in the following, unless otherwise specified, "parts" means parts by weight, and "%" means % by weight.

manufacture example 1

[0233] 1) Raw material production example 1 [production of compound (a1)]

[0234] 301 parts (4.18 moles) of acrylic acid and pentaerythritol [manufactured by Guangei Chemical Co., Ltd.] were mixed in a 4-necked flask equipped with a thermometer, a stirrer, a water-cooled condenser, and a blowing port while blowing nitrogen gas containing 5% by volume of oxygen. Hereinafter referred to as "PE"] 167 parts (1.23 moles), sulfuric acid 7 parts, hydroquinone monomethyl ether (hereinafter referred to as "MEHQ") 0.14 parts and toluene 224 parts, at a reaction temperature of about 80°C and 370 Torr (absolute pressure) While removing condensation water, it was allowed to react until 45 mol% of all hydroxyl groups in PE were esterified.

[0235] The generated condensation water was 28 parts, and 42 parts of unreacted PE were recovered. 870 parts of toluene were added after completion|finish of reaction.

[0236] Under stirring, a 20% aqueous sodium hydroxide solution was added in an a...

manufacture example 2

[0238] 2) Raw material production example 2 [production of compound (a1)]

[0239] Except for using 301 parts of acrylic acid (4.18 mol), 167 parts of PE (1.23 mol), 7 parts of sulfuric acid, 0.14 parts of MEHQ, and 224 parts of toluene, it was reacted while removing condensation water under the same conditions as in Raw Material Production Example 1. Up to 30% of all hydroxyl groups in PET are esterified.

[0240] 18 parts of condensation water were produced, and 83.5 parts of unreacted PE were recovered. 870 parts of toluene were added after completion|finish of reaction.

[0241] By the same operation as in raw material production example 1, using the same amount of sodium hydroxide aqueous solution and water, neutralization treatment and water washing treatment were performed, and then toluene was distilled off.

[0242] The obtained acrylate was 120 parts, and the hydroxyl value was 224 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com