Non-woven fabric laminate and method for production thereof

A non-woven fabric layer and non-woven fabric technology, applied in the field of non-woven fabric laminates and their manufacturing, can solve the problems of insufficient stretchability, softness, and processability, and achieve less sticking and excellent curl resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

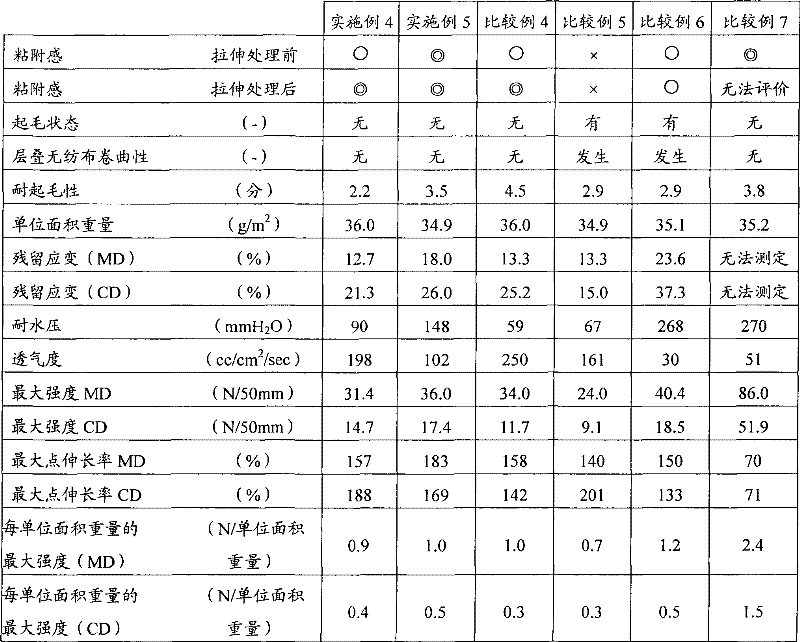

[0120] Hereinafter, the present invention will be described more specifically in conjunction with examples, but the present invention is not limited to these examples.

[0121] The physical property values and the like in Examples and Comparative Examples were measured by the following methods.

[0122] (1) Weight per unit area [g / m 2 ]

[0123] Take 6 test pieces of 200 mm (MD) x 50 mm (CD) from the nonwoven fabric and / or the nonwoven fabric laminate. Among them, the positions for taking the test piece are MD and CD at any 3 positions (a total of 6 positions). Next, the mass (g) of each obtained test piece was measured using the upper-pan electronic balance (manufactured by Kenseiko Kogyo Co., Ltd.). Calculate the mass average value of each test piece. Converted from the obtained average value to the equivalent of 1m 2 The mass (g) of each non-woven fabric sample is rounded off to the second place after the decimal point, and it is used as the weight per unit area of ...

manufacture example 1

[0178] In a nitrogen atmosphere, diphenylmethane diisocyanate (hereinafter referred to as MDI) was put into tank A, and the temperature was adjusted to 45° C. while stirring without mixing air bubbles.

[0179] In a nitrogen atmosphere, 628.6 parts by weight of polyester polyol with a number average molecular weight of 2000 (manufactured by Mitsui Takeda Chemical Co., Ltd., trade name: Takeraku U2024), 2.21 parts by weight of IRGANOX 1010 and 77.5 parts by weight of 1,4-butanediol were packed. Put it into tank B and adjust to 95°C while stirring. This mixture is referred to as polyol solution 1.

[0180] The hard segment amount calculated from these reaction raw materials was 37.1% by weight.

[0181] Then, through the infusion pipeline provided with a gear pump and a flow meter in the middle, the MDI is quantitatively delivered to a high-speed mixer (SM40) adjusted to 120° C. ), after stirring and mixing at 2000rpm for 2 minutes, it was delivered to a static mixer. The sta...

Embodiment 1

[0185]

[0186] The MFR of 96 parts by weight (according to ASTM D1238, measured at a temperature of 230°C and a load of 2.16 kg) is 60 g / 10 minutes, and the density is 0.91 g / cm 3 , a propylene homopolymer with a melting point of 160°C (hereinafter referred to as "PP-1") and 4 parts by weight of MFR (according to ASTM D1238, measured at a temperature of 190°C and a load of 2.16kg) is 5g / 10min, and the density is 0.97g / cm 3 and high-density polyethylene (hereinafter referred to as "HDPE") having a melting point of 134° C. were mixed to prepare a thermoplastic resin composition (B-1).

[0187]

[0188] The TPU-1 prepared in the above-mentioned Production Example 1 and the above-mentioned B-1 were independently melted with an extruder (ф30 mm), and then a spunbonded non-woven fabric forming machine with a spinning nozzle (with The length of the direction perpendicular to the direction of travel of the machine is 100mm), the temperature of the resin and the die are both 220...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com