Processing technology of curl-resistance PE cast film

A processing technology and casting film technology, which is applied in the processing technology field of anti-curling PE casting film, can solve the problems of poor flatness and poor curl resistance, and achieve fast production speed, good curl resistance and excellent balance performance in all directions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

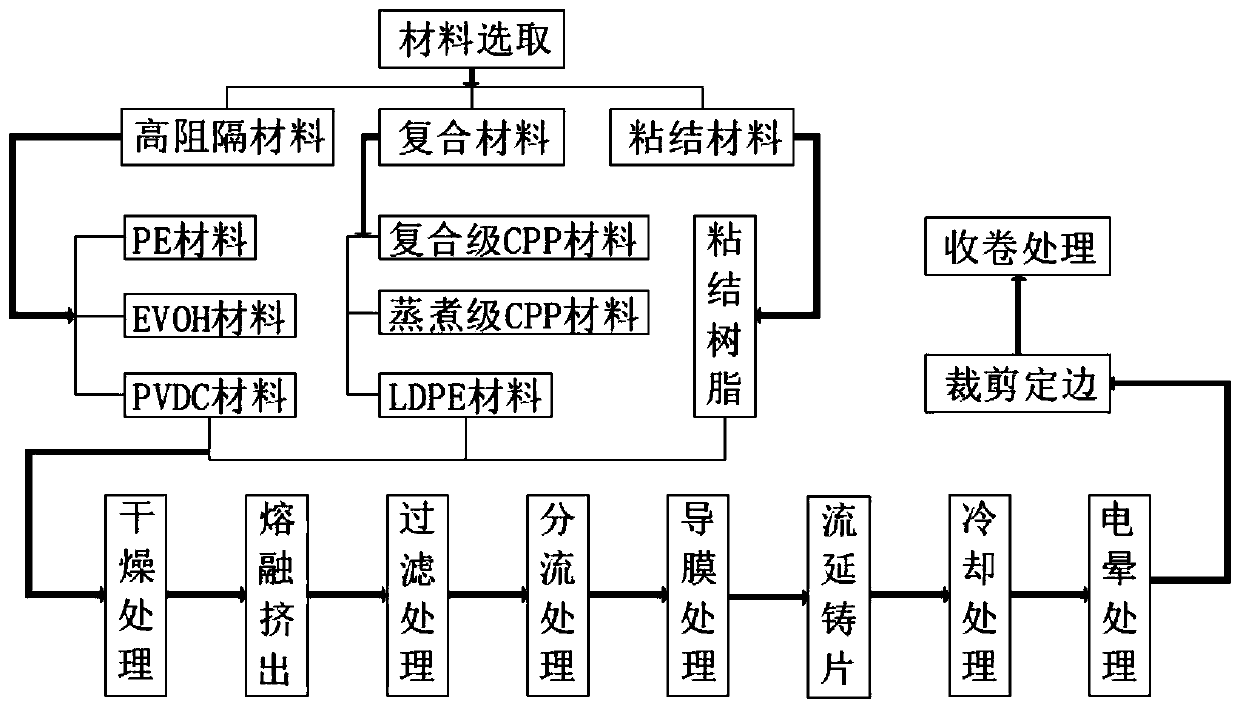

[0026] see figure 1 , a processing technology of anti-curling PE cast film, raw materials include high barrier material, composite material and bonding material, wherein the content of high barrier material is 60%, the content of composite material is 80%, the content of bonding material is 50%, and Dry and melt the selected materials. The high barrier material is PE material, and the composite material is composite grade CPP pellets, and its MI value is between 8. Firstly, the raw materials are selected, and the bonding material is bonding resin. When the value is 8, the bonding material is made of bonding resin, and its MI value is between 6. After the selection is completed, use a dryer to dry it, and then use a multi-component metering, weighing and feeding device to inject the raw materials into the extrusion In the machine, the high-barrier material, composite material and adhesive material are melted and extruded separately, and then the melt is filtered and layered and...

Embodiment 2

[0039] see figure 1, a processing technology of anti-curling PE cast film, raw materials include high barrier material, composite material and bonding material, wherein the content of high barrier material is 40%, the content of composite material is 60%, the content of bonding material is 30%, and The selected material is subjected to dry melting treatment, the high barrier material is PVDC material, the composite material is LDPE material, and its MI value is 4, and the bonding material is selected from bonding resin, and its MI value is between 2 After the selection is completed, dry it with a dryer, then use a multi-component metering and weighing feeding device to inject the raw materials into the extruder, and melt and extrude the high barrier material, composite material and bonding material respectively , and then filter the melt, and perform layered splitting treatment on it. Co-extrusion distributors, single-channel and multi-channel dies can be used to achieve split...

Embodiment 3

[0052] see figure 1 , a processing technology of anti-curling PE cast film, raw materials include high barrier material, composite material and bonding material, wherein the content of high barrier material is 50%, the content of composite material is 70%, the content of bonding material is 40%, and The selected material is subjected to dry melting treatment, the high barrier material is at least one of PE material, EVOH material and PVDC material, and the composite material is at least one of composite grade CPP pellets, cooking grade CPP material and LDPE material One, and its MI value is 6, and the bonding material is selected from bonding resin, and its MI value is 4.

[0053] A processing technology of anti-curling PE casting film, comprising the following steps:

[0054] (1), firstly select the raw material, after the selection is completed, dry it with a dryer, the drying temperature is 85°C, and the drying time is 25min;

[0055] (2), then use multi-component meterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com