Release film

A technology for release film and film, applied in the field of polystyrene release film, to achieve the effects of excellent curl resistance, sufficient curl resistance, and excellent heat-resistant dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

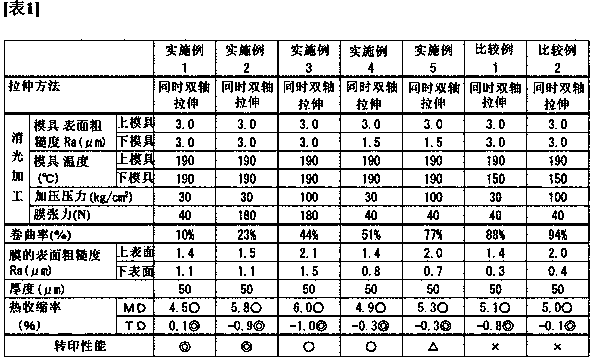

[0092] Examples 1-5 / Comparative Examples 1-2

[0093] A mixture of the following components was melted and extruded through a T-die at a resin temperature of 280° C. using an extruder, and then cooled to obtain an unstretched film (precursor film). The unstretched film is subjected to the stretching step under the conditions described below. The stretching process includes a stretching treatment and a heat setting treatment, and the heat setting treatment performs a relaxation heat setting treatment at a predetermined temperature and a relaxation magnification. It should be noted that the stretching treatment is simultaneous biaxial stretching.

[0094] As mixture components, both Examples and Comparative Examples used a syndiotactic polystyrene resin, an antioxidant, and a lubricant.

[0095] As the syndiotactic polystyrene resin, "Zareck 142ZE" (manufactured by Idemitsu Kosan Co., Ltd., glass transition temperature 95° C., melting point 247° C.) was used.

[0096] As the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com