High temperature resistant release paper and preparation method thereof

A technology of high temperature resistant and release paper, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of high cost and immature production technology, and achieve the effect of low cost and good temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

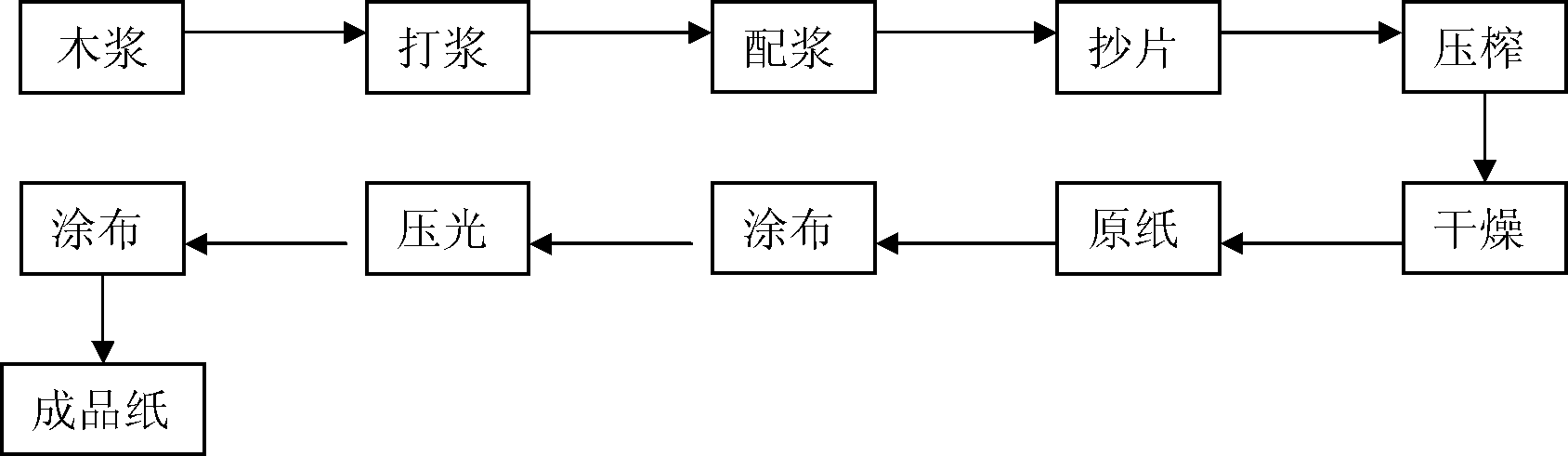

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of preparation method of high temperature resistant type release paper, the steps are as follows in parts by weight:

[0030] (1) Slurry preparation: Soak kraft bleached softwood pulp boards in water for 4 hours, concentrate the concentration of the slurry to a water weight content of 10%, and refine in a PFI refiner for 5 minutes. Keep the beating degree of the pulp at 30-35°SR; concentrate the ground pulp again, disperse the pulp into a sealed bag, and balance the moisture at room temperature for 24 hours, measure the dry fiber content of the pulp for future use .

[0031] (2) Preparation of dry paper sheets: Weigh the slurry according to the required area of the product, weigh 0.5 parts of the humidifying enhancer and 10 parts of the inorganic high temperature resistant auxiliary agent for every 100 parts of the slurry; and inorganic high-temperature-resistant additives are fully separated in the fiber separator, the rotating speed is 2800~3000...

Embodiment 2

[0035] Embodiment 2 A kind of preparation method of high temperature resistant release paper, the steps are as follows in parts by weight:

[0036] (1) Slurry preparation: Soak kraft bleached softwood pulp boards in water for 3 hours, concentrate the concentration of the pulp to about 5%, and refine in a PFI refiner for 3 minutes to make the pulp The degree of beating is 30-35°SR; concentrate the ground slurry, disperse the slurry into a sealed bag, and balance the water at room temperature for 24 hours, and measure the dry fiber content of the slurry for later use.

[0037](2) Tablet copying: Weigh the slurry according to the required area of the product, weigh 0.25 parts of the humidifying strength agent and 2 parts of the inorganic high temperature resistance additive for every 100 parts of the slurry; The high-temperature additives are fully separated in the fiber separator, the speed is 2800~3000r / min, and the separation time is 8min; the dispersed pulp is sheeted in th...

Embodiment 3

[0041] Embodiment 3 A kind of preparation method of high temperature resistant type release paper, the steps are as follows in parts by weight:

[0042] (1) Slurry preparation: Soak kraft bleached softwood pulp boards in water for 5 hours, concentrate the concentration of the pulp to about 15%, and refine in a PFI refiner for 5 minutes to make the pulp The degree of beating is 30-35°SR; concentrate the ground slurry, disperse the slurry into a sealed bag, and balance the water at room temperature for 24 hours, and measure the dry fiber content of the slurry for later use.

[0043] (2) Tablet copying: Weigh the slurry according to the required area of the product, weigh 0.75 parts of the humidifying enhancer and 12 parts of the inorganic high temperature resistant auxiliary agent for every 100 parts of the slurry; The high-temperature additives are fully separated in the fiber separator, the speed is 2800~3000r / min, and the separation time is 12min; the dispersed pulp is shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com