High-lustre mirror transferring coated paper as well as production technology and production equipment thereof

A production process, coated paper technology, applied in the field of paper processing, can solve the problems of only 20-60 m/min, expensive processing equipment, low surface smoothness, etc., to achieve good printing effect, high smoothness, high whiteness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

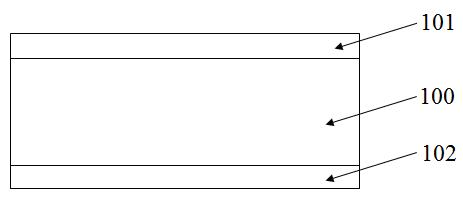

[0028] Such as figure 1 As shown, a high-gloss specular transfer coated paper, glossy gloss ≥ 90 (75 degrees), including a paper layer 100, a paper glossy coating 101 and a paper back coating 102, the thickness of the paper layer 100 is 80- 350um, the paper smooth coating 101 is a styrene-acrylic resin coating layer with a thickness of 0.5-2um, and the paper back coating 102 is a styrene-acrylic resin coating layer with a thickness of 0.5-2um.

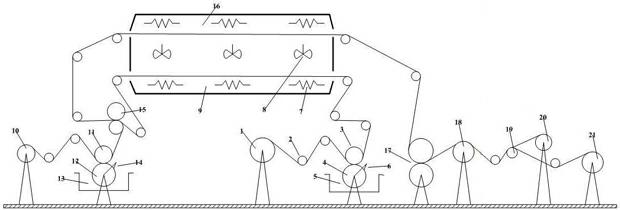

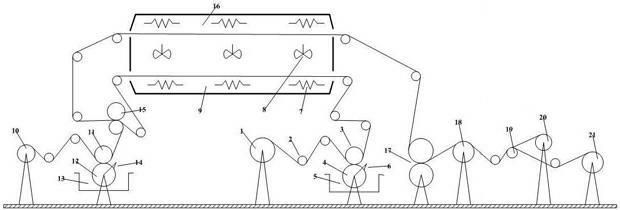

[0029] A production equipment and production process of high-gloss mirror transfer coated paper, such as figure 2 As shown, it includes paper unwinding equipment, composite equipment, coating and drying equipment, cooling equipment, peeling equipment, and winding equipment arranged in sequence along the paper travel route, and film unwinding equipment and composite equipment arranged in sequence along the film travel route ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com