Opening intensive type printed circuit board covering film

A printed circuit board, opening-intensive technology, applied in the direction of printed circuit parts, synthetic resin layered products, layered products, etc., can solve the problems of low hygroscopicity, low basis weight, etc., achieve low hygroscopicity and reduce the environment Pollution, excellent curl resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

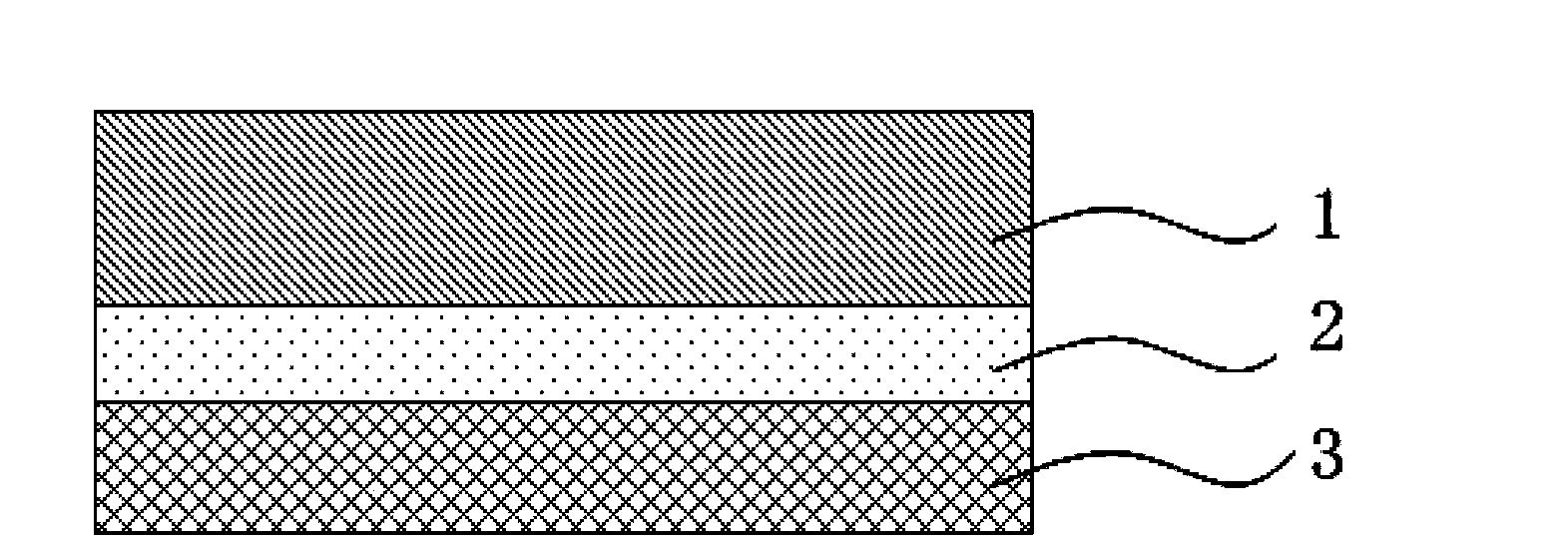

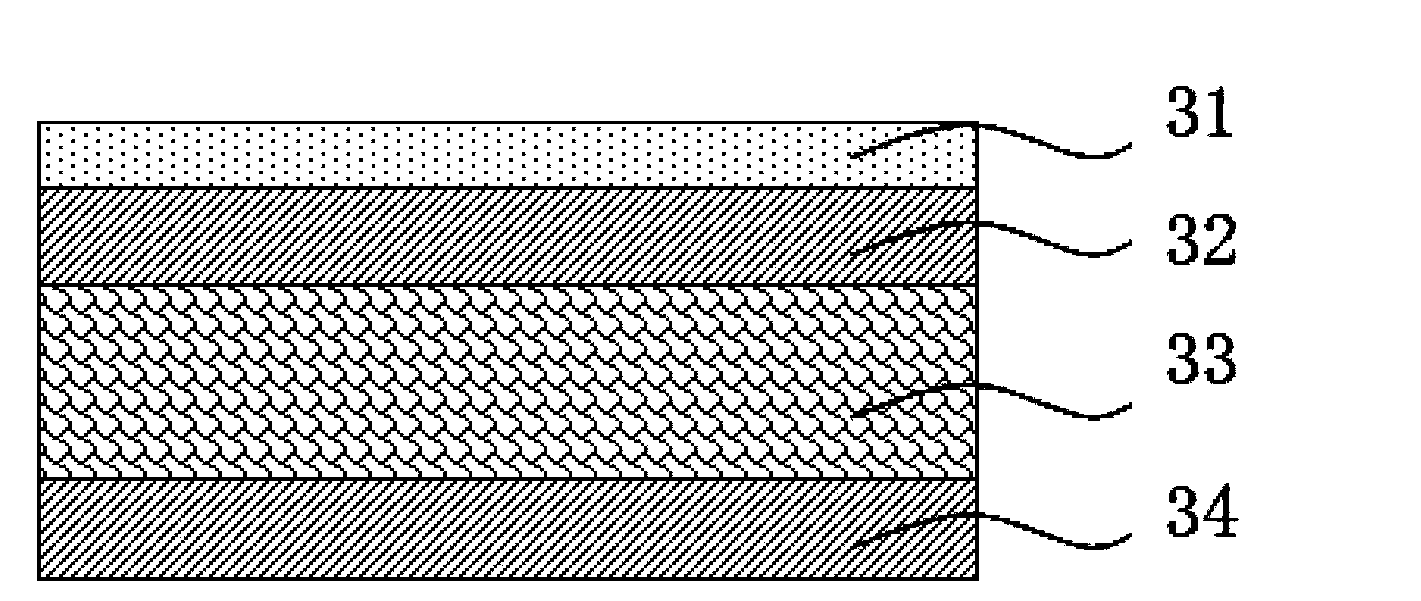

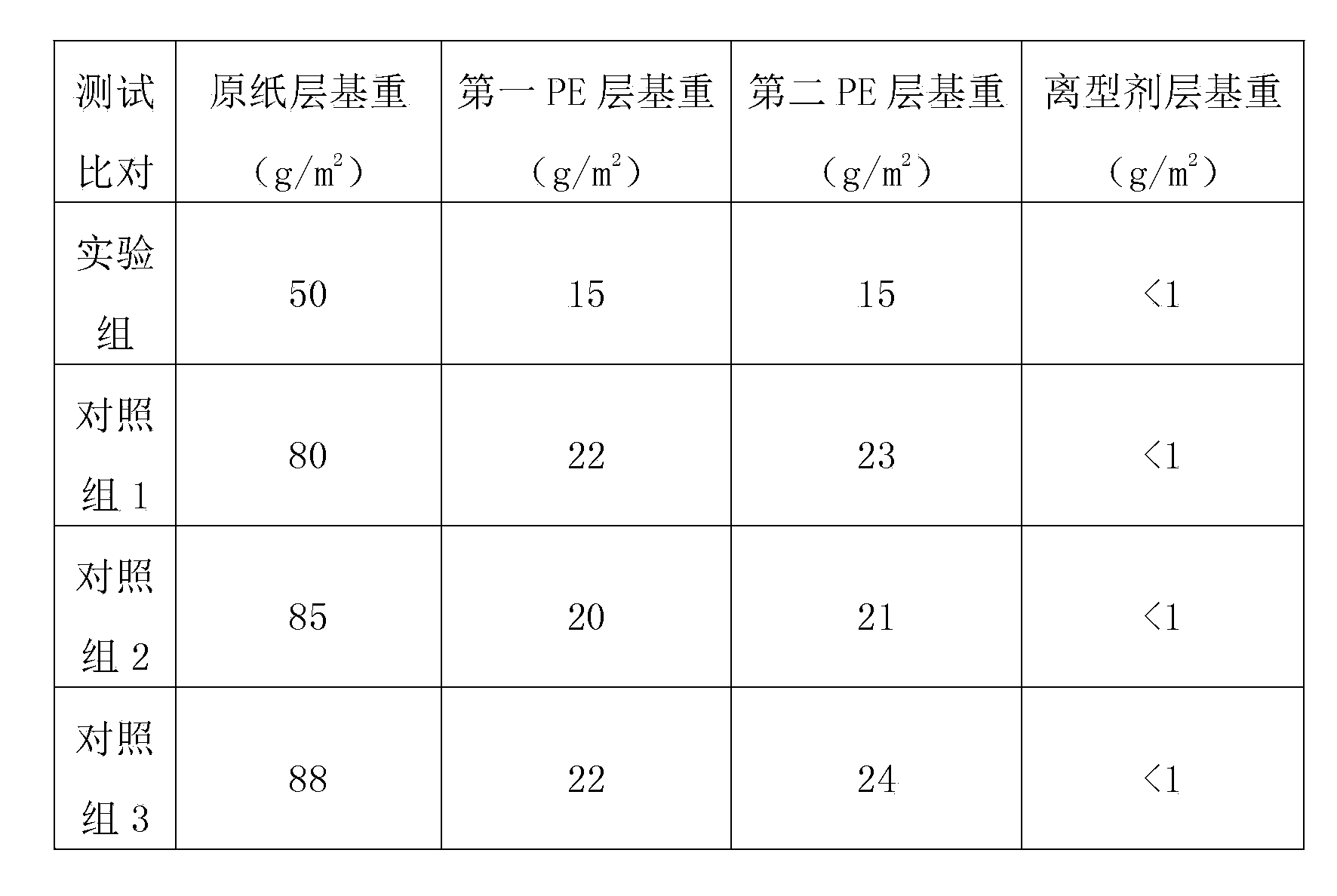

[0020] Embodiment: A cover film for an opening-intensive printed circuit board, which is composed of a polyimide film 1, an adhesive layer 2 and a release paper 3, and the release paper is successively composed of a release agent layer 31, a first PE layer 32. Base paper layer 33 and second PE layer 34, the thickness of the release agent layer 31 is less than 1 micron, the thickness of the first PE layer 32 is 10-20 microns, and the thickness of the base paper layer 33 is 40 ~60 microns, the thickness of the second PE layer 34 is 10~30 microns, the thickness of the release paper 3 is 90~100 microns, and the basis weight of the release paper 3 is 40~60g / m 2 , the release force of the release paper 3 is 2-8g / 5cm.

[0021] The thickness of the cover film of the present invention can meet the following conditions: the thickness of the adhesive layer and the polyimide film is the same or the sum of the thicknesses of the two is equal to 12 microns, so that the cover film of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com