Bag for automatic cheese canning

An automatic tank and cheese technology, applied in the field of packaging bags, can solve the problems that ordinary materials cannot meet the requirements of cheese and cheese packaging, and does not consider the sealing form of packaging bags, etc., achieving high strength, no local stress concentration, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

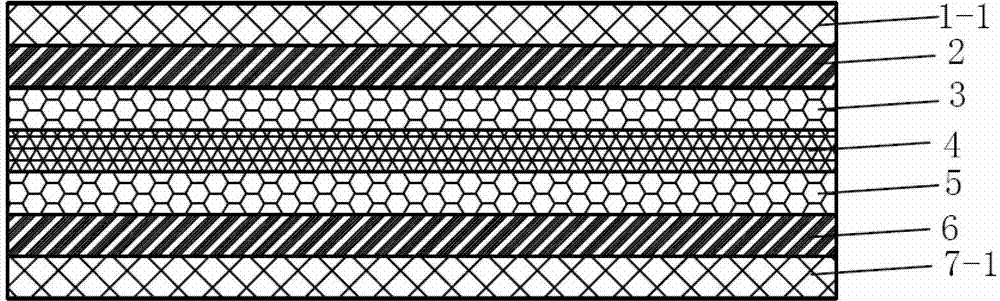

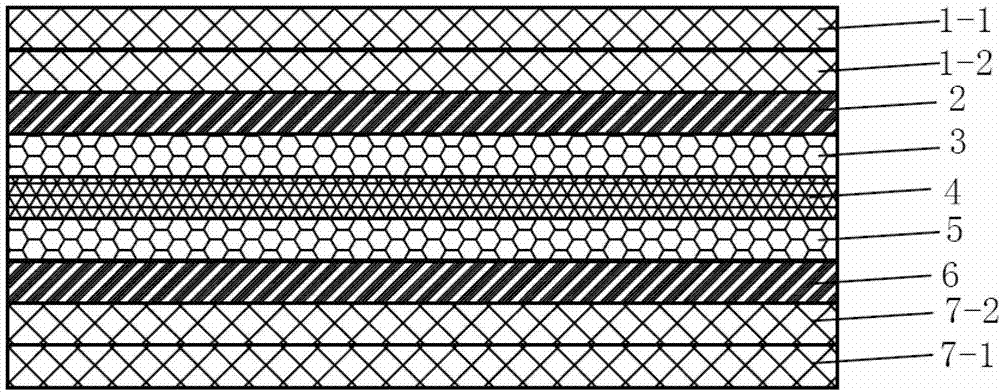

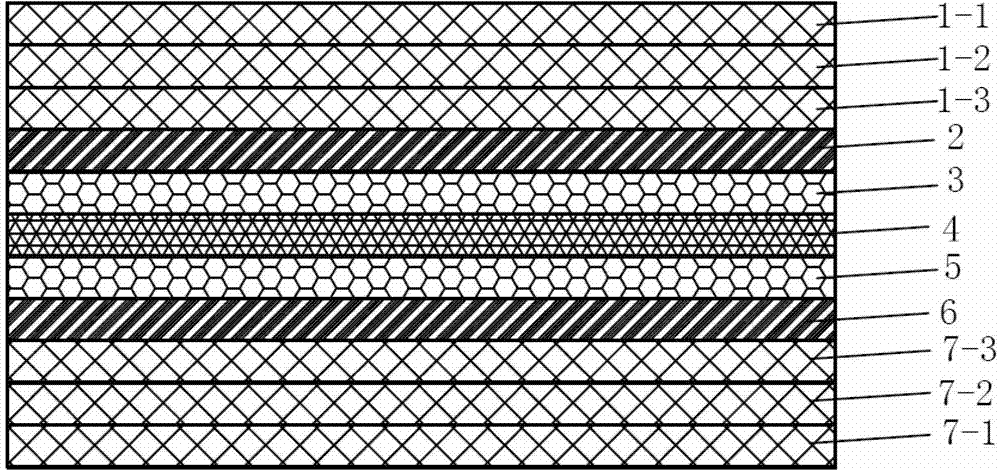

[0033] The present invention is a bag for automatic canning of cheese, which includes a bag body 10 with an inserting structure, the bag body 10 is composed of a layered co-extruded blown film with a symmetrical structure and the number of layers is seven to eleven layers. Each layer of the blown co-extruded film is laid symmetrically with respect to the fragrance-preserving core layer 4, and its structure is as follows: Figures 1 to 3 shown. The symmetrical laying here means that the two layers in the symmetrical position use the same resin material and have the same thickness. Symmetrical laying can make the bag body 10 have high anti-curling performance, so the film will not curl when heat sealing or even subsequent cheese canning, and the three-dimensional structure of the bag body 10 can be more stable.

[0034] like figure 1 As shown, the layered blown co-extruded film can be provided with an inner heat-sealed moisture barrier layer 1-1, an inner adhesive layer 2, an ...

Embodiment 2

[0044] On the basis of Embodiment 1, the preferred embodiment of the present invention is: the inserting edge 13-1, 13-2 of the bag body 10 is sandwiched between the oblique sealing line 15 and the bottom sealing line 14 and the area between the front side 11 and the bottom sealing line 14 respectively. The back side 12 is heat-sealed together to form four mutually independent oblique sealing areas 16, such as Figure 9 and Figure 10 shown. The setting of the inclined sealing area 16 can improve the stability of the three-dimensional structure of the bag body 10 and the strength of the bottom of the bag body 10 .

[0045] In addition, a carrying hole 17 is provided on the top of the bag body 10 to facilitate the handling of the bag body 10 after the cheese cans are filled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com