Preparation method of water-based leather release paper

A release paper and leather technology, applied in special paper, paper, papermaking and other directions, can solve the problems of insufficient pattern haze, unguaranteed quality stability of synthetic leather, poor anti-curling effect of release paper, etc. Guaranteed quality stability, avoiding curling, good anti-curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

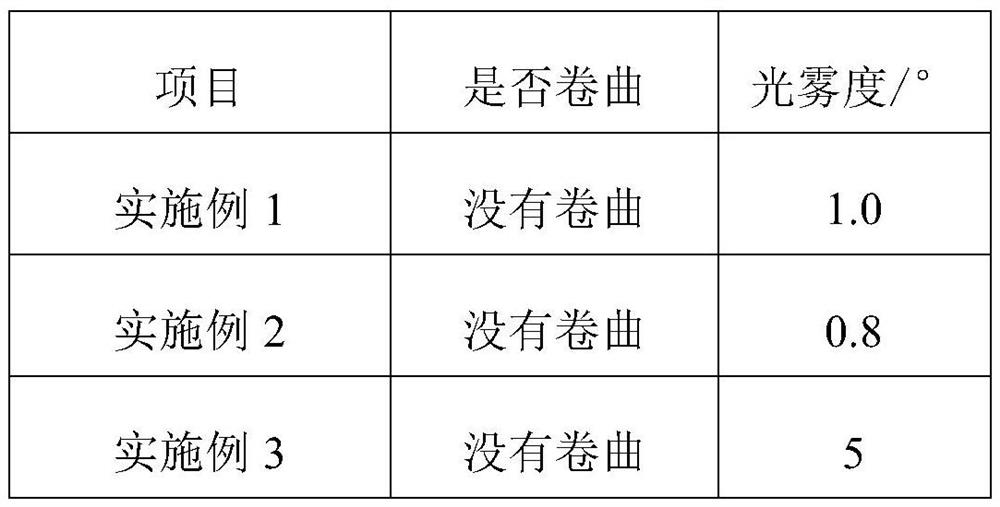

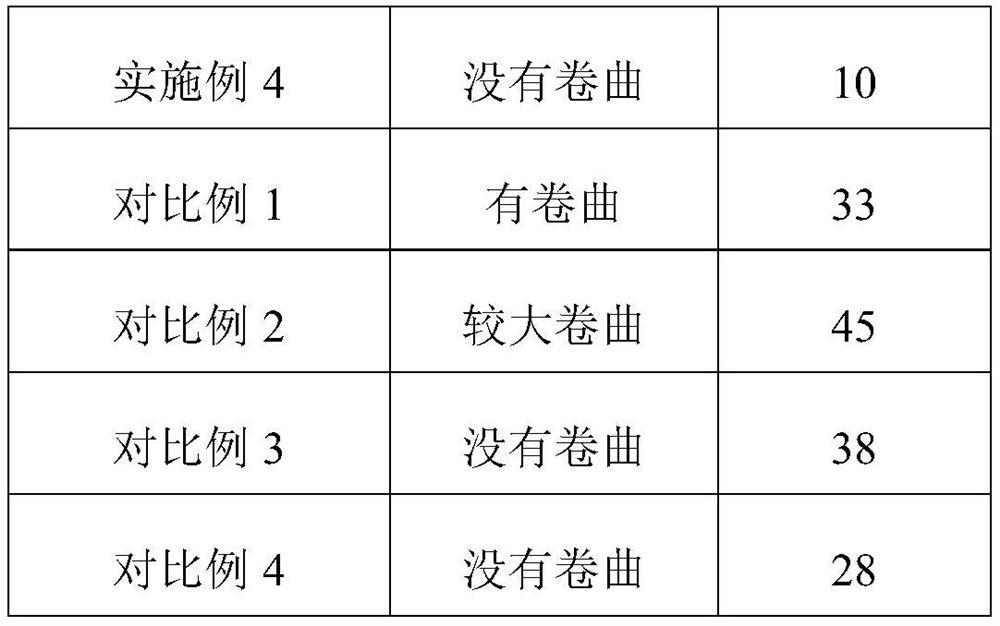

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of water-based leather release paper, comprises the steps:

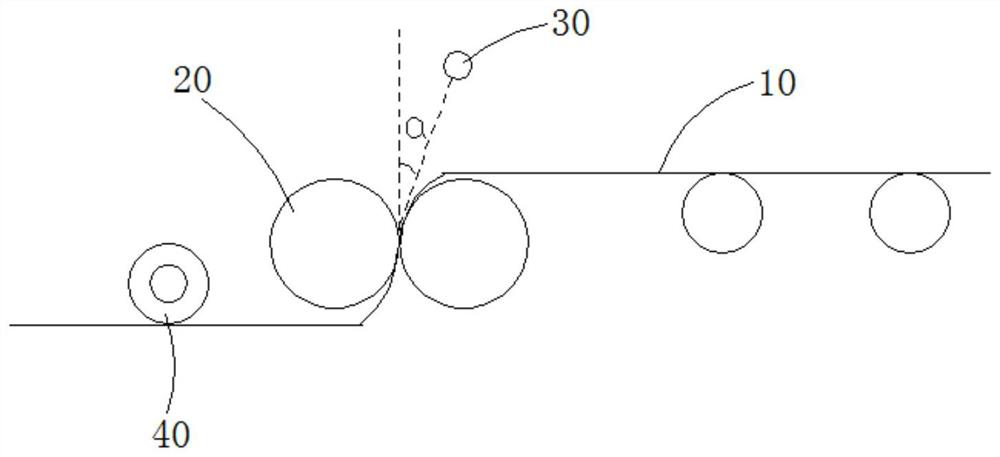

[0027] S1: provide base paper 10, coating materials and a coating machine, the coating machine includes a patterned roller 20, an auxiliary roller in contact with the surface of the patterned roller 20, a coating head 30 located at the upper end of the patterned roller 20, and A cooling roll 40 positioned at the rear end of the patterned roll 20;

[0028] S2: Put the base paper 10 between the pattern roller 20 and the auxiliary roller, pour the coating material through the coating head 30 to the middle of the pattern roller 20 and the base paper 10, and apply the coating material to the base paper 10 through the pattern roller 20 Pressure, so that the surface of base paper 10 forms a layer of coating material with a pattern structure to obtain a semi-cured release paper, wherein the coating direction of the coating head 30 is tangential to the contact point o...

Embodiment 1

[0037] A preparation method of water-based leather release paper, comprising the steps of:

[0038] S1: provide base paper 10, coating materials and a coating machine, the coating machine includes a patterned roller 20, an auxiliary roller in contact with the surface of the patterned roller 20, a coating head 30 located at the upper end of the patterned roller 20, and A cooling roll 40 positioned at the rear end of the patterned roll 20;

[0039]S2: Put the base paper 10 between the pattern roller 20 and the auxiliary roller, pour the coating material through the coating head 30 to the middle of the pattern roller 20 and the base paper 10, and apply the coating material to the base paper 10 through the pattern roller 20 pressure, so that the surface of the base paper 10 forms a coating material layer with a textured structure, the temperature of the patterned roller 20 is 10°C-15°C, the pressing speed is 10r / min-15r / min, and the pressing force is 1N-3N, Obtain semi-cured rele...

Embodiment 2

[0042] A preparation method of water-based leather release paper, comprising the steps of:

[0043] S1: provide base paper 10, coating materials and a coating machine, the coating machine includes a patterned roller 20, an auxiliary roller in contact with the surface of the patterned roller 20, a coating head 30 located at the upper end of the patterned roller 20, and A cooling roll 40 positioned at the rear end of the patterned roll 20;

[0044] S2: Put the base paper 10 between the pattern roller 20 and the auxiliary roller, pour the coating material through the coating head 30 to the middle of the pattern roller 20 and the base paper 10, and apply the coating material to the base paper 10 through the pattern roller 20 pressure, so that the surface of the base paper 10 forms a coating material layer with a textured structure, the temperature of the patterned roller 20 is 10°C-15°C, the pressing speed is 10r / min-15r / min, and the pressing force is 1N-3N, Obtain semi-cured rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com