High-chromium nickel-based superalloy, diesel engine gas valve and diesel engine gas valve manufacturing process

A high-chromium nickel-based, manufacturing process technology, applied in the direction of manufacturing tools, metal processing equipment, valve devices, etc., can solve the problem of improving the performance of Ni80A nickel-based superalloy gas valves, narrow range of electric upsetting process parameters, and prone to dynamic hardening and cracks and other problems, to achieve the effect of improving high temperature creep resistance, improving hot processing performance, and small stress change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The high-chromium nickel-based superalloy in this embodiment contains the following essential elements in terms of mass percentage: 35% Cr, 1.0% Al, 0.2% Fe, 0.1% Co; the balance is Ni and impurities.

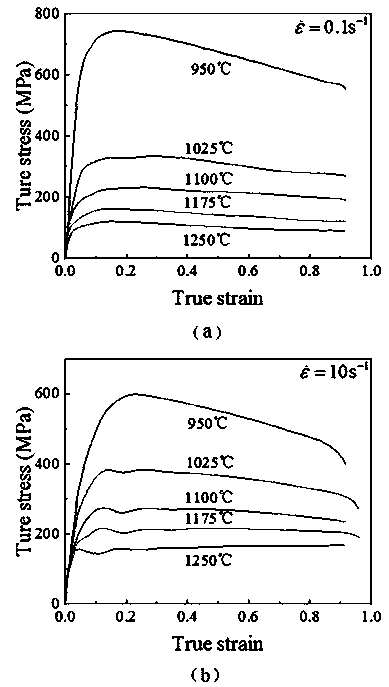

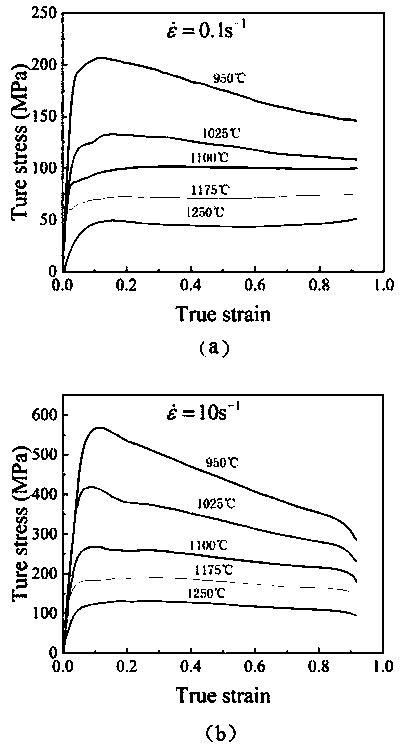

[0037] The high-chromium nickel-based superalloy in this embodiment is subjected to stress-strain tests at different temperatures and strain rates, and the test results are as follows image 3 shown. The stress-strain test result of the Ni80A nickel-based superalloy material in the prior art is as follows figure 2 shown.

[0038] Compared figure 2 and image 3 It can be seen that the high-chromium-nickel-based superalloy in this example is at two identical strain rates ( and ) and five same temperatures (950°C, 1020°C, 1100°C, 1175°C and 1250°C), the stresses are all less than the stress values of Ni80A; in the process of electric upsetting, the deformation resistance is small, the deformation is more uniform, and plastic forming better.

[0039] At the same...

Embodiment 2

[0068] The difference between this embodiment and embodiment 1 lies in the composition of the high-chromium nickel-based superalloy and the number of segments in the high-order segmented dynamic loading mode. The composition of the high-chromium nickel-based superalloy in this embodiment is 45% Cr, 5% Al, 15% Fe, 10% Co; the balance is Ni and impurities. The number of segments in the high-order segment dynamic loading mode is 40 segments.

[0069] The high-chromium nickel-based superalloy in this embodiment is subjected to stress-strain tests at different temperatures and strain rates, and the test results are as follows Figure 7 shown. The stress-strain test result of the Ni80A nickel-based superalloy material in the prior art is as follows figure 2 shown.

[0070] Compared figure 2 and Figure 7 It can be seen that the high-chromium-nickel-based superalloy in this example is at two identical strain rates ( and ) and four same temperatures (950°C, 1100°C, 1150°C a...

Embodiment 3-5

[0082] Table 6 Comparison of formulations of high-chromium nickel-based superalloys

[0083]

[0084] Combination 1: C: 0.08%; Si: 0.33%; B: 0.01%; Cu: 0.36%; Ti: 0.08%; Nb: 0.06%; 0.2%;

[0085] Combination 2: C: 0.08%; Si: 0.42%; B: 0.01%; Cu: 0.34%; Ti: 0.1%; Nb: 0.1%; Ta: 0.04%; V: 0.07%; 0.4%;

[0086] Combination 3: C: 0.1%; Si: 0.36%; B: 0.01%; Cu: 0.33%; Ti: 0.08%; Nb: 0.06%; 0.35%;

[0087] Among them, the addition of optional elements can further improve the properties of the alloy: Ti and Nb elements can form a γ’ precipitation strengthening phase with Ni, and better high-temperature strength can be obtained. At the same time, Nb also has good strong thermal properties. C element is an indispensable element in steel and also a high-strength carbide-forming element. Usually, C in heat-resistant steel precipitates in the form of carbide during aging, which can improve the mechanical properties. Si is a beneficial element for high temperature corrosion resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com