Self-cleaning pipeline

A self-cleaning, pipeline technology, applied in the field of pipelines, can solve the problems of blockage and easy accumulation of dirt on the inner wall of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

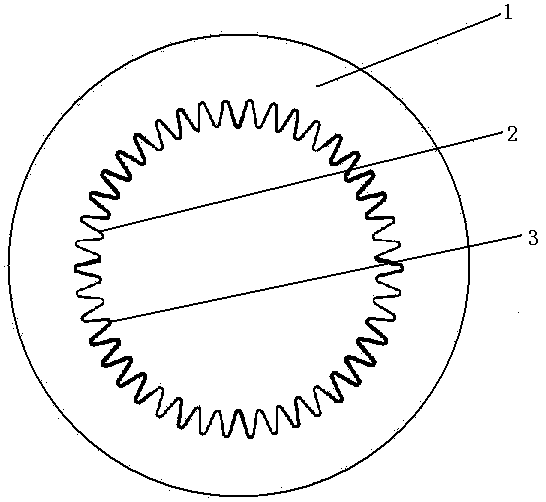

Embodiment 1

[0026] Such as figure 1 As shown, a self-cleaning pipe is made, including the pipe body, which is made of homopolypropylene (PP-H) by injection molding, and of course it can also be made of other materials. In this embodiment, the inner wall surface of the pipe body is made into a wrinkled shape, specifically, the inner wall surface of the pipe body is made into an arc-turned folded shape from the longitudinal direction.

[0027] After the inner surface of the pipe is designed to be wrinkled, the extrusion on the inner surface becomes uneven due to thermal expansion and contraction, so that the convex part of the uneven wrinkled inner surface will be more convex, and because the pipe body has Due to the thickness, the change range of the concave part will be relatively small, so because the change range of different positions on the inner surface of the inner wall is not synchronized, the dirt attached to the inner surface will be dislocated and gradually detached, so that the...

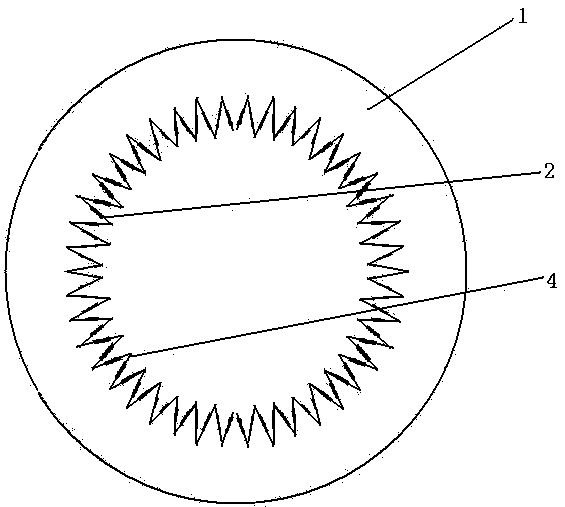

Embodiment 2

[0029] Such as figure 2 As shown, a self-cleaning pipe is produced, including a pipe body, which is injection-molded from random copolymerized polypropylene (PP-R). In this embodiment, the inner wall surface of the pipe body is made into a wrinkled shape, specifically The inner wall surface of the pipe body is made into a straight-folded shape from the longitudinal direction.

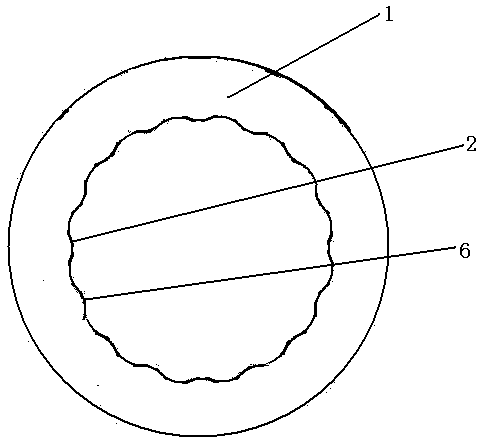

Embodiment 3

[0031] Such as image 3 As shown, a self-cleaning pipe is produced, including a pipe body, which is made of block copolymer polypropylene (PP-B) by injection molding. In this embodiment, the inner wall surface of the pipe body is made into a wrinkled shape, specifically The inner wall surface of the pipe body is made into an arc folded shape from the longitudinal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com