Preparation process of freezing-resistant crystal balls

A preparation process and technology of crystal balls are applied in the field of preparation technology of freeze-resistant crystal balls, which can solve the problems such as easy damage of ice crystal gel structure, and achieve the effects of good effect, reducing moisture and enhancing freezing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

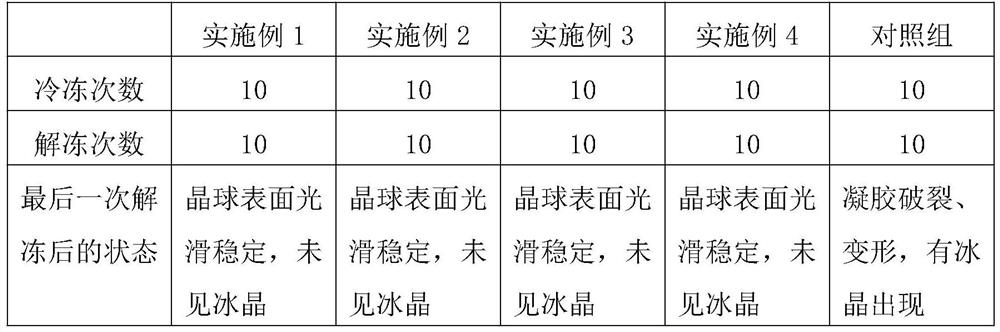

Examples

Embodiment 1

[0028] Preparation of cryospheres

[0029] Weigh 10g of sodium alginate, 8g of agar, 10g of carrageenan, 8g of konjac gum, and 10g of locust bean gum powder, and mix evenly to obtain a mixed powder. Mix the mixed powder, sugar, and water in a weight percentage ratio of 1:5:30 to fully Dissolve, add 2g of water-soluble emulsifier polysorbate 80 and stir evenly, add coconut oil with a weight percentage of 10%, to obtain a mixed colloid; heat the mixed colloid to 88°C; in the heat preservation state, pump the heated mixed colloid to the molding machine, and then drop it into calcium water above 60°C at a rate of 20 pcs / min, the high-temperature sodium alginate will form instantly, and other colloids will remain in the colloidal form, then drain the gel particles, put them in ice water, Slowly lower the granules to 20°C; take out the gel granules, add white sugar, the weight ratio of the gel granules and white sugar is 7:3, stir well to make the sugar fully melt; adjust the acidit...

Embodiment 2

[0031] Weigh 20g of sodium alginate, 15g of agar, 15g of carrageenan, 12g of konjac gum, and 15g of locust bean gum powder, mix them evenly to obtain a mixed powder, and fully mix the mixed powder, sugar, and water according to the weight percentage of 2:15:45. Dissolve, add 2g of water-soluble emulsifier sodium stearate and stir evenly, add coconut oil with a weight percentage of 12%, to obtain mixed colloid; heat the mixed colloid to 92°C; in the heat preservation state, pump the heated mixed colloid to the molding machine, and then drop it into calcium water above 60°C at a speed of 30 pcs / min, the high-temperature sodium alginate is formed instantly, and other colloids remain in the colloidal form, then the gel particles are drained out, put into ice water, and the gel Slowly lower the granules to 20°C; take out the gel granules, add white granulated sugar, the weight ratio of the gel granules and white granulated sugar is 9:1, stir evenly to fully melt the sugar; adjust th...

Embodiment 3

[0033] Weigh 20g of sodium alginate, 15g of agar, 15g of carrageenan, 12g of konjac gum, and 15g of locust bean gum powder, mix them evenly to obtain a mixed powder, and fully mix the mixed powder, sugar, and water according to the weight percentage of 2:15:45. Dissolve, add 2g of water-soluble emulsifier sodium stearate and stir evenly, add coconut oil with a weight percentage of 12%, to obtain the mixed colloid; heat the mixed colloid to 90°C; in the heat preservation state, pump the heated mixed colloid to the molding machine, and then drop it into calcium water above 60°C at a speed of 30 pcs / min, the high-temperature sodium alginate is formed instantly, and other colloids remain in the colloidal form, then the gel particles are drained out, put into ice water, and the gel Slowly lower the granules to 20°C; take out the gel granules, add white sugar, the weight ratio of the gel granules and white sugar is 8:2, stir well to make the sugar fully melt; adjust the acidity, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com