Method for preparing ordered mesoporous carbon

A mesoporous carbon and pre-carbonization technology, which is applied in the field of preparation of ordered mesoporous carbon materials, can solve the problems of low carbon yield and inability to obtain ordered mesoporous carbon materials, and achieve high carbon formation rate, low price, Effect of improving carbon yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 4g of P123 (analytical grade, Aldrich) and 1g of sucrose in 160ml of hydrochloric acid solution with a molar concentration of 2M, stir well at 35°C, and after it dissolves, add 9.2ml of tetraethyl orthosilicate (with sucrose) dropwise The dosage ratio is 9.2ml / g), after continuing to stir for 24 hours, put it in an oven at 100°C for 24 hours to stand for crystallization, then filter, wash and dry at room temperature to obtain the sucrose / P123 / silicon ternary complex. Mix 1g of the ternary compound with 10ml of water and 1ml of sulfuric acid with a concentration of 98% and mix and stir for 12 hours. After filtering, put the resulting precipitate in an oven at 160°C for 6 hours for pre-carbonization; the ternary compound after pre-carbonization Under the protection of nitrogen, the temperature was raised to 800°C at a heating rate of 1°C / min for carbonization, and after 2 hours of heat preservation, it was naturally cooled to room temperature to obtain a carbon / si...

Embodiment 2

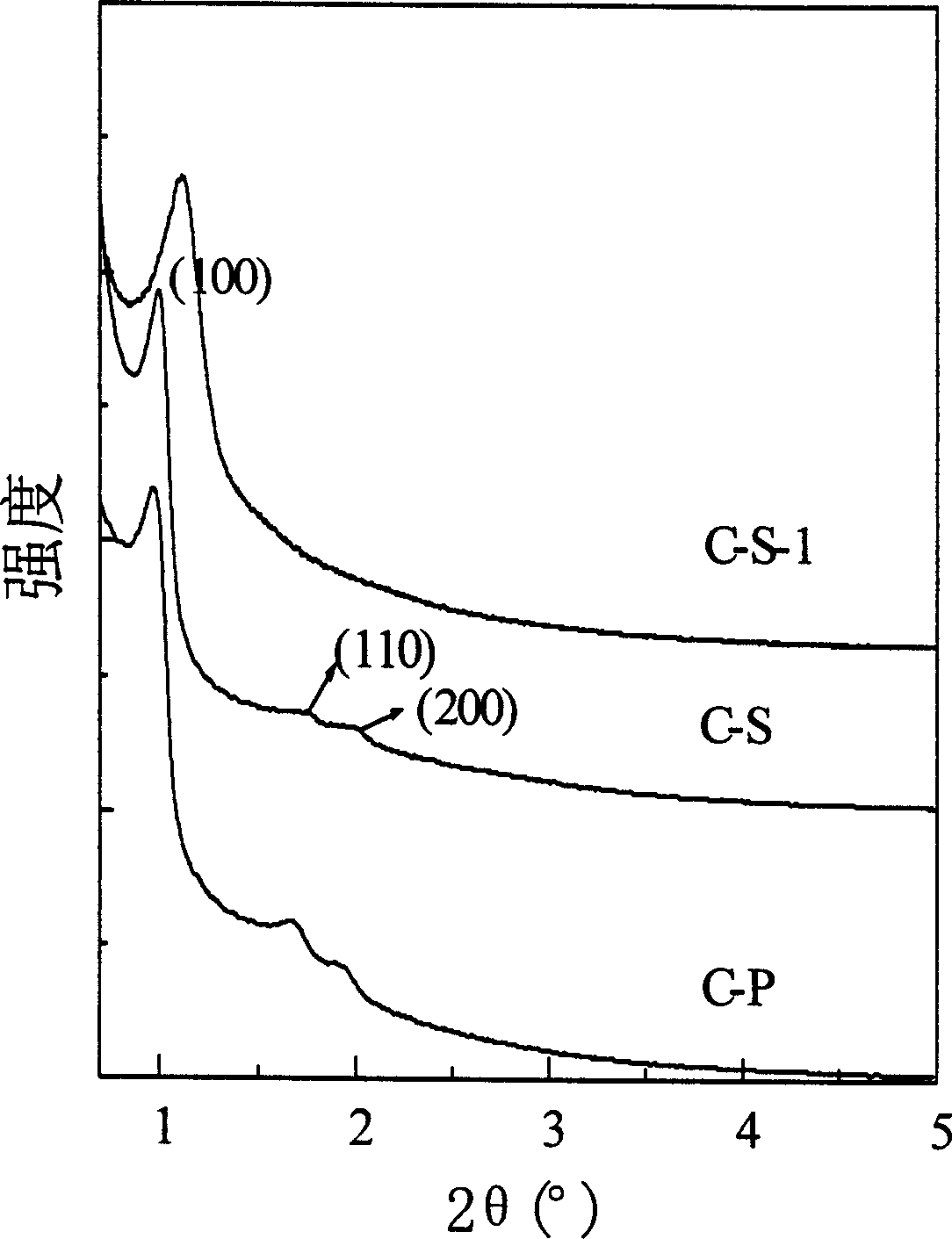

[0030] The operation method is the same as in Example 1, except that the dosage of P123 is 3.75g and the dosage of sucrose is 1.25g (the mass ratio of P123 to sucrose is 3:1, and the ratio of ethyl orthosilicate to sucrose is 7.4ml / g) , finally obtained 0.59g mesoporous carbon. XRD analysis test shows that the obtained material is a mesoporous carbon with two-dimensional hexagonal structure arrangement, d 100 8.2nm, unit cell parameter a 0 9.5nm.

Embodiment 3

[0032] The operation method is the same as that in Example 1, except that the sucrose / P123 / silicon ternary complex was synthesized by crystallization at a crystallization temperature of 80° C. for 24 hours, and finally 0.52 g of mesoporous carbon was obtained. XRD analysis test shows that the obtained material is a mesoporous carbon with two-dimensional hexagonal structure arrangement, d 100 7.8nm, unit cell parameter a 0 9.0nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell parameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com