Preparation method of nano-ternary complex lithium-ion battery cathode material

A lithium-ion battery and ternary composite technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of affecting material performance, non-concentrated particle size distribution, long reaction time and energy consumption, and achieve the goal of improving consistency performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Lithium nitrate, nickel nitrate, cobalt nitrate, and manganese nitrate were dissolved in deionized water to form a homogeneous solution, wherein the molar ratio of Li:Ni:Co:Mn was 1:0.2:0.5:0.3, and all the metals were added after mixing the above solutions. Citric acid with 3 times the amount of ionic substances is used as a metal ion chelating agent and fully stirred, and the mixed solution is moved into a water bath and heated at a constant temperature of 95°C until a sol is formed, and the obtained sol is vacuum-dried at 120°C. Sinter at 850°C for 10 hours to obtain α-NaFeO with primary particle size below 100nm 2 Type LiNi 0.2 co 0.5 mn 0.3 o 2 Cathode material.

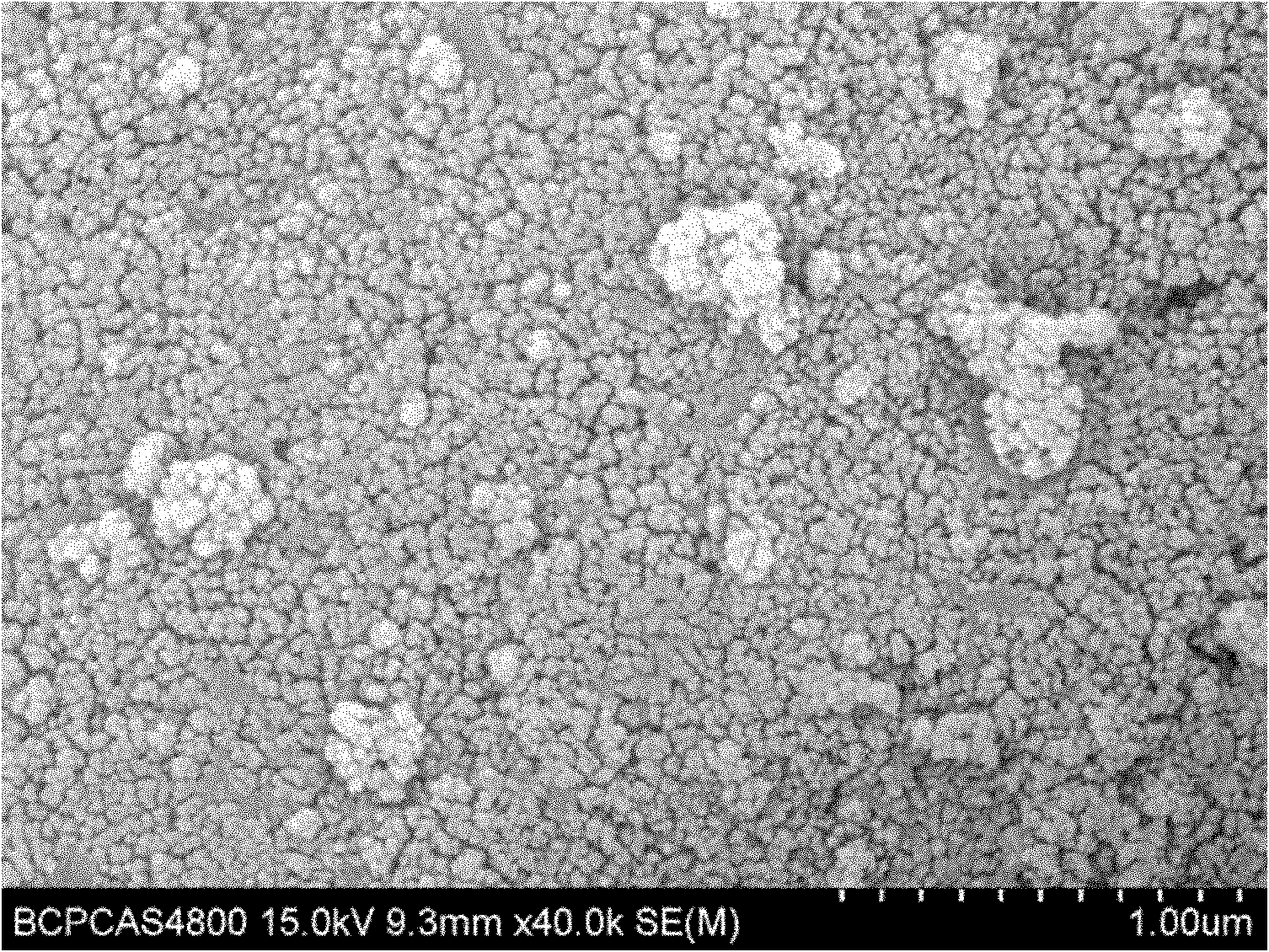

[0020] see figure 1 It is shown that the sample prepared by this process method has the characteristics of concentrated particle size distribution and primary particle size less than 100nm. This process method effectively avoids the ball milling treatment process adopted by the high-temperature soli...

Embodiment 2

[0022] Lithium nitrate, nickel acetate, cobalt oxalate, and manganese nitrate were dissolved in deionized water to form a homogeneous solution, wherein the molar ratio of Li:Ni:Co:Mn was 1:0.2:0.6:0.2, and all the metals were added after mixing the above solutions. Citric acid with 5 times the amount of ionic substances is used as a metal ion chelating agent and fully stirred. The mixed solution is moved into a water bath and heated at a constant temperature of 85°C until a sol is formed. The resulting sol is vacuum-dried at 100°C. Sintering at 750°C in air for 22 hours to obtain α-NaFeO with primary particle size below 100nm 2 Type LiNi 0.2 co 0.6 mn 0.2 o 2 Cathode material.

Embodiment 3

[0024] Dissolve lithium nitrate, nickel sulfate, cobalt oxalate, and manganese nitrate in deionized water to form a homogeneous solution, in which the molar ratio of Li:Ni:Co:Mn is 1:0.4:0.2:0.4, mix the above solutions and add all the metals Citric acid with 2 times the amount of ionic substances is used as a metal ion chelating agent and fully stirred, and the mixed solution is moved into a water bath and heated at a constant temperature of 90°C until a sol is formed, and the obtained sol is vacuum-dried at 100°C. Sinter at 900°C in air for 8 hours to obtain α-NaFeO with primary particle size below 100nm 2 Type LiNi 0.4 co 0.2 mn 0.4 o 2 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com