Method for removing sulfate radical from injected water in oil field for anti-scaling

A technology for desulfurization and water injection, which is applied in chemical instruments and methods, earthwork drilling, cleaning tools, etc., can solve problems such as difficult treatment and limited effect of chemical methods, and achieve the effect of ensuring stable production and reducing water injection pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Scale prevention method for desulfurization of injected water in oilfields. Nanofiltration membrane desulfurization device is used to pretreat the injected water so that the injected water is divided into clean water and concentrated water, and then the clean water is injected downhole.

[0035] The whole process of pretreatment of nanofiltration membrane desulfurization unit is as follows:

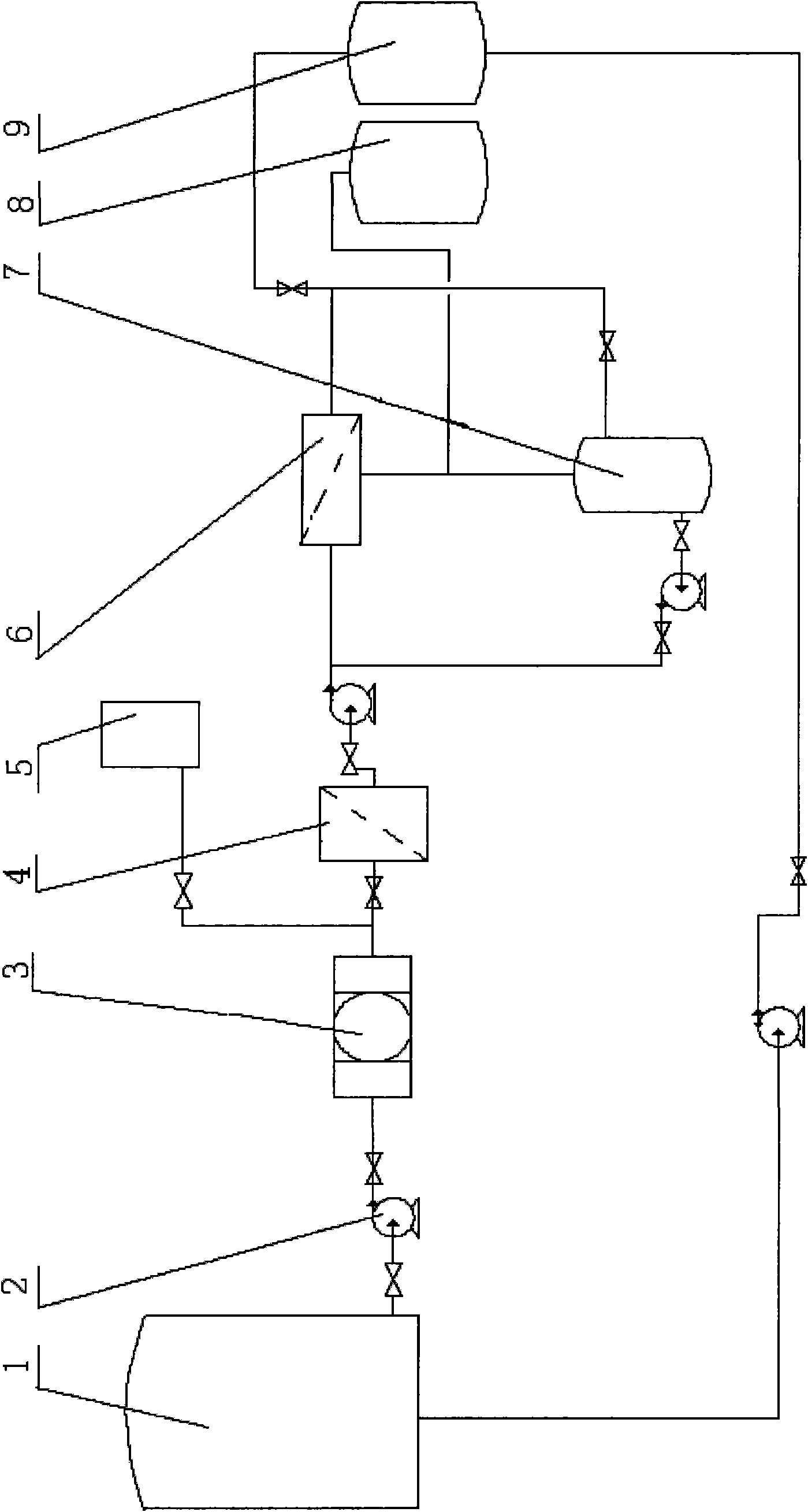

[0036] A. First, the injected water enters the source water tank 1, and then through the high-pressure pump 2, the injected water in the source water tank 1 enters the coarse filtration system 3 for coarse filtration treatment. The model adopted by the coarse filtration system 3 is XLDJZ-4.

[0037] B. Then, the injected water filtered by the coarse filtration system 3 enters the fine filtration system 4 for processing. The model adopted by the fine filtration system 4 is XLJM-3.

[0038] C. After the injection water is filtered in two stages by the coarse filtration s...

Embodiment 2

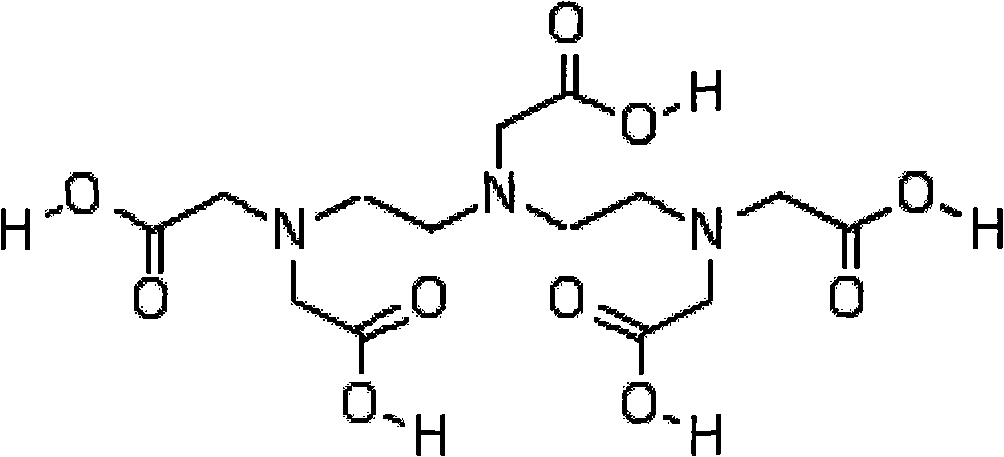

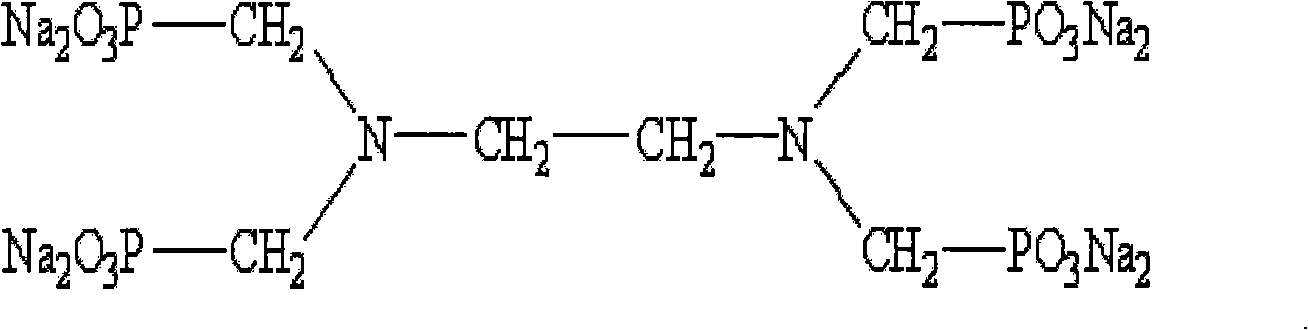

[0044] Embodiment 2: The difference with Example 1 is: the component parts by weight of the ternary complex cleaning agent are: 63.1 parts of diethylenetriaminepentaacetic acid (DTPA); sodium ethylenediamine tetramethylene phosphonate (EDTMPS ) 36.2 parts; linear alkylbenzene sulfonate sodium (LAS) 0.7 part, what the anionic surfactant (LAS) adopted was sodium tetradecylbenzene sulfonate.

Embodiment 3

[0045] Embodiment 3: The difference with Example 1 is: the component parts by weight of the ternary complex cleaning agent are: 58.5 parts of diethylenetriaminepentaacetic acid (DTPA); sodium ethylenediamine tetramethylene phosphonate (EDTMPS ) 41.1 parts; anionic surfactant (LAS) 0.4 part, what anionic surfactant (LAS) adopted is sodium dodecylbenzenesulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com