Antibiosis rare earth ternary complexes and preparation method and application thereof

A ternary complex and rare earth technology, applied in the field of antibacterial materials, can solve the problems of narrow range of antibacterial materials, weak antibacterial effect, no application of antibacterial activity, etc., and achieve good chemical stability, thermal stability, and antibacterial effect Visible, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Under the condition of heating and refluxing in a water bath at 50°C, add a certain amount of Schiff base ligand and add absolute ethanol to dissolve it, and slowly add RECl with a molar ratio of 1:2 to the Schiff base ligand under constant stirring. 3 ·xH 2 O (in advance by RE 2 o 3 reacted with hydrochloric acid), reacted under the above conditions for 2 hours, added the dehydrated ethanol solution of o-phenanthroline with an equimolar number of Schiff base ligands, continued to react for 4 hours, cooled to room temperature and suction filtered , the filtrate was concentrated to 12mL, a large number of yellow precipitates were formed when diethyl ether was added, filtered with suction, and the precipitates were washed with diethyl ether for 3 to 4 times to obtain RE(L)(A)(H 2 O), the resulting complex was vacuum-dried at room temperature at 50° C. for 2 h and then sealed and stored.

[0047] In the above method, L is Schiff base salicylaldehyde phenylalanine or Sch...

Embodiment 2

[0050] Under the condition of heating and refluxing in a water bath at 65°C, add a certain amount of Schiff base ligand and add absolute ethanol to dissolve it, and slowly add RECl with a molar ratio of 1:2 to the Schiff base ligand under constant stirring. 3 ·xH 2 O (in advance by RE 2 o 3 prepared by reacting with hydrochloric acid), reacted for 2.5 hours under the above-mentioned reaction conditions, added an absolute ethanol solution of a heterocyclic compound having an equimolar number of Schiff base ligands, continued to react for 3 hours, cooled to room temperature, and suction filtered. Concentrate the filtrate to 10mL, add diethyl ether to form a large amount of yellow precipitate, filter with suction, wash the precipitate with diethyl ether 3 to 4 times to obtain RE(L)(A)(H 2 O), the resulting complex was vacuum-dried at room temperature at 45° C. for 3 h and then sealed and stored.

[0051] Note: L is Schiff base salicylaldehyde phenylalanine or Schiff base salic...

Embodiment 3

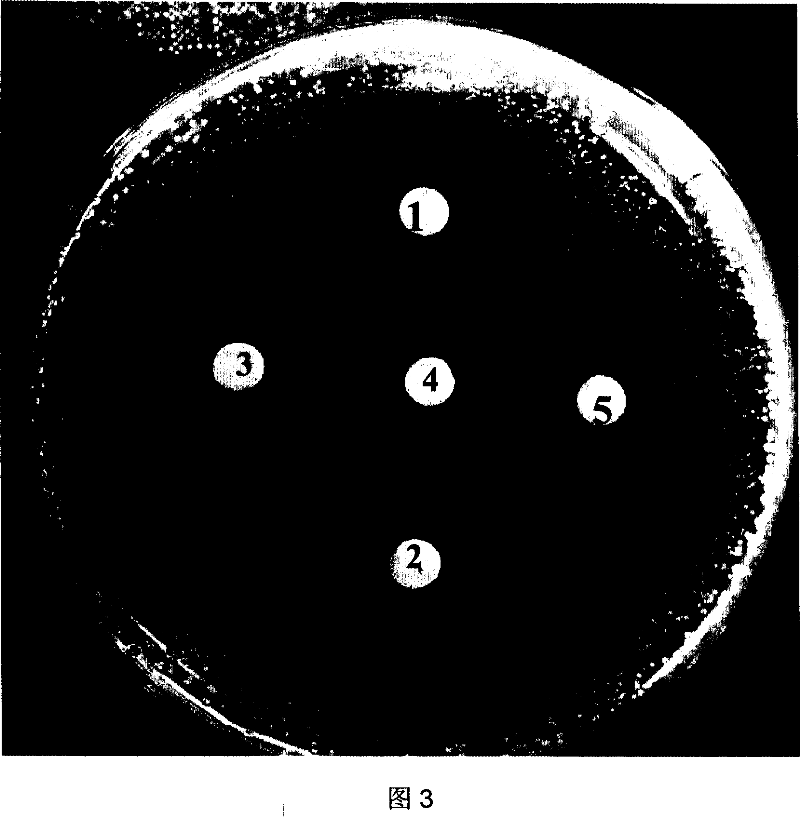

[0054] The various complexes prepared in Examples 1 and 2 were tested for minimum inhibitory concentration respectively, and the data are as follows: the MIC result data of the complex to Escherichia coli is in the range of 30ppm~65ppm, and the MIC result data to Staphylococcus aureus is in the range of 100ppm ~300ppm range (the smaller the MIC, the better the antibacterial effect).

[0055] The result shows that the MIC of the obtained complex is much lower than the regulation of antibacterial agent MIC<800ppm stipulated in the chemical industry standard of the People's Republic of China, and the antibacterial effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com