Method for preparing Lactobacillus casei microcapsule

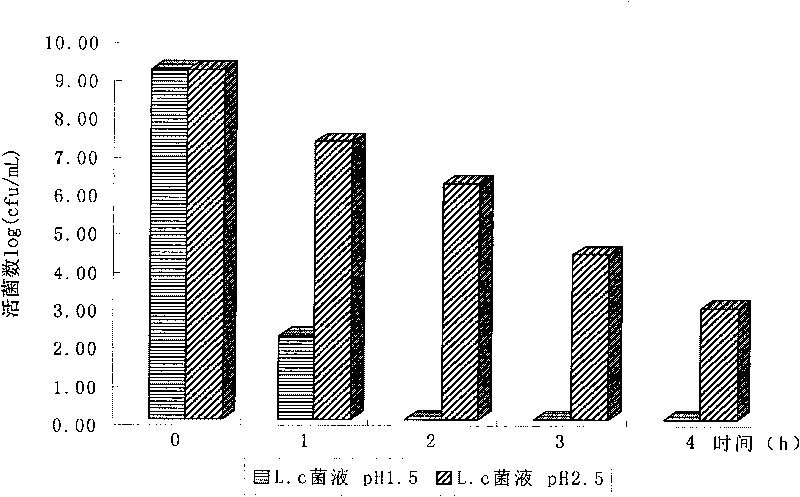

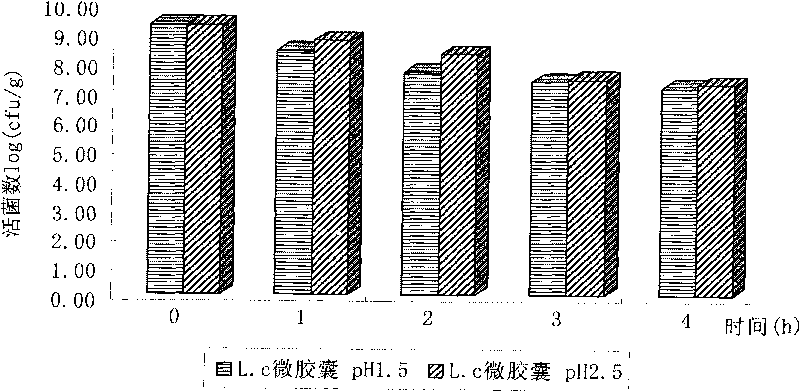

A technology of Lactobacillus casei and microcapsules, applied in the biological field, can solve the problems that the probiotic function cannot be fully utilized, cannot be rapidly disintegrated in the intestinal tract, and the wall material does not have good enteric solubility, so as to achieve rich varieties and strong acid resistance , Stable effect of bile salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Firstly, inoculate the strains in the liquid MRS medium, culture according to the optimum culture temperature, and subculture after the medium is turbid. After 2 to 3 times of activation, the strains were fully recovered and used for subsequent experiments. After the vigor of the bacteria reaches the requirement, the bacteria are collected. Put the bacterial solution into the tube under aseptic conditions, and centrifuge with a refrigerated centrifuge. The centrifugal force is 4000g. After centrifuging for 20 minutes, discard the supernatant and keep the centrifuged bacteria. Then it is diluted with physiological saline, and the bacterium suspension cell concentration of 0.5% concentration can reach 108~109cfu / mL. Mix the Lactobacillus casei suspension with the first layer of embedding material 4% microporous starch solution 1:1 (V / V), 180r / min, and stir for 15min until absorbed; then add 4% sodium alginate solution, add The volume ratio of the above mixed solution i...

Embodiment 2

[0029] Firstly, the strains were inoculated in skim milk medium, cultured at 37°C, and then subcultured after solidification. After 2-3 activations, the strains were fully recovered and then used for subsequent experiments. After the cell viability meets the requirements, add 4% sodium citrate solution, fully stir for 40 minutes, and then collect the cells. Put the bacterial solution into the tube under aseptic conditions, and centrifuge with a refrigerated centrifuge. The centrifugal force is 10000g. After centrifuging for 50min, discard the supernatant and keep the centrifuged bacteria. Then dilute with normal saline, the concentration of 0.5% bacterial suspension thalline concentration can reach 10 9 cfu / mL. Mix Lactobacillus casei suspension with the first layer of embedding material 5% microporous starch solution 1:1 (V / V), 160r / min, 20min and stir until absorbed; then add 5% sodium alginate solution, add The volume ratio of the amount to the above mixed solution is 2:...

Embodiment 3

[0031] Firstly, the strains were inoculated in skim milk medium and cultured at 37°C. After 2 to 3 activations, the strains were fully recovered and then used for subsequent experiments. Inoculate the bacteria into the MRS medium modified with whey protein hydrolyzate, add sterilized phosphate buffer, culture for 14 hours, and then collect the bacteria. Put the bacterial solution into the tube under aseptic conditions, and centrifuge with a refrigerated centrifuge. The centrifugal force is 6000g. After centrifuging for 20min, discard the supernatant and keep the centrifuged bacteria. Then dilute with normal saline, the concentration of 0.5% bacterial suspension thalline concentration can reach 10 9 cfu / mL. Mix the suspension of Lactobacillus casei with the first layer of embedding material 5% microporous starch solution 1:1 (V / V), stir at 190r / min for 20min until absorbed; then add 5% sodium alginate solution, add The volume ratio of the amount to the above mixed solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com