Multiphase Fenton catalyst as well as preparation method and application thereof

A catalyst, Fenton's technology, applied in the field of heterogeneous Fenton-like catalyst and its preparation and application, can solve the problems of poor mechanical strength, large amount of dissolved ions, etc., to reduce the dosage, reduce chemical sludge, and promote decomposition. and the effect of COD removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

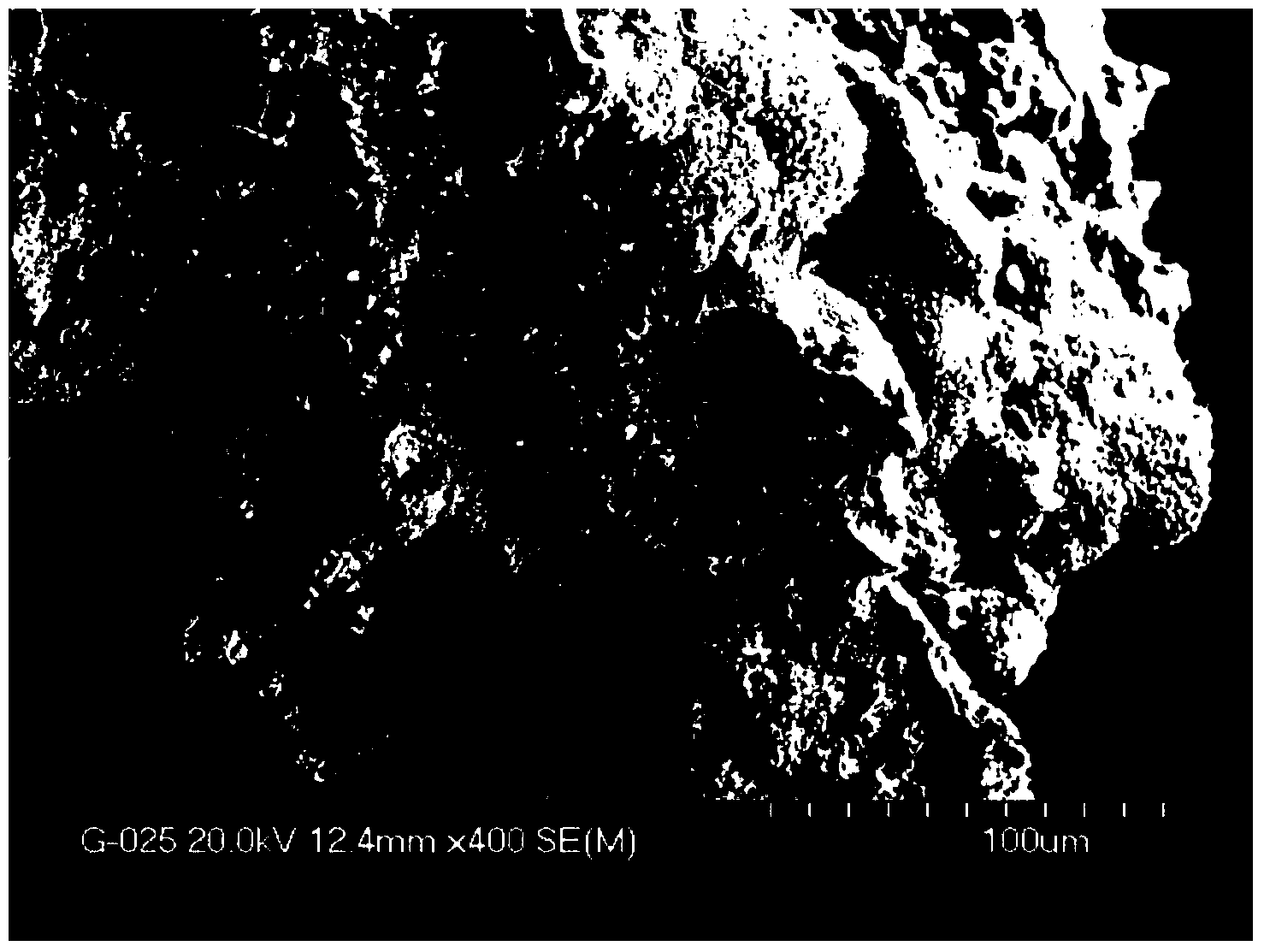

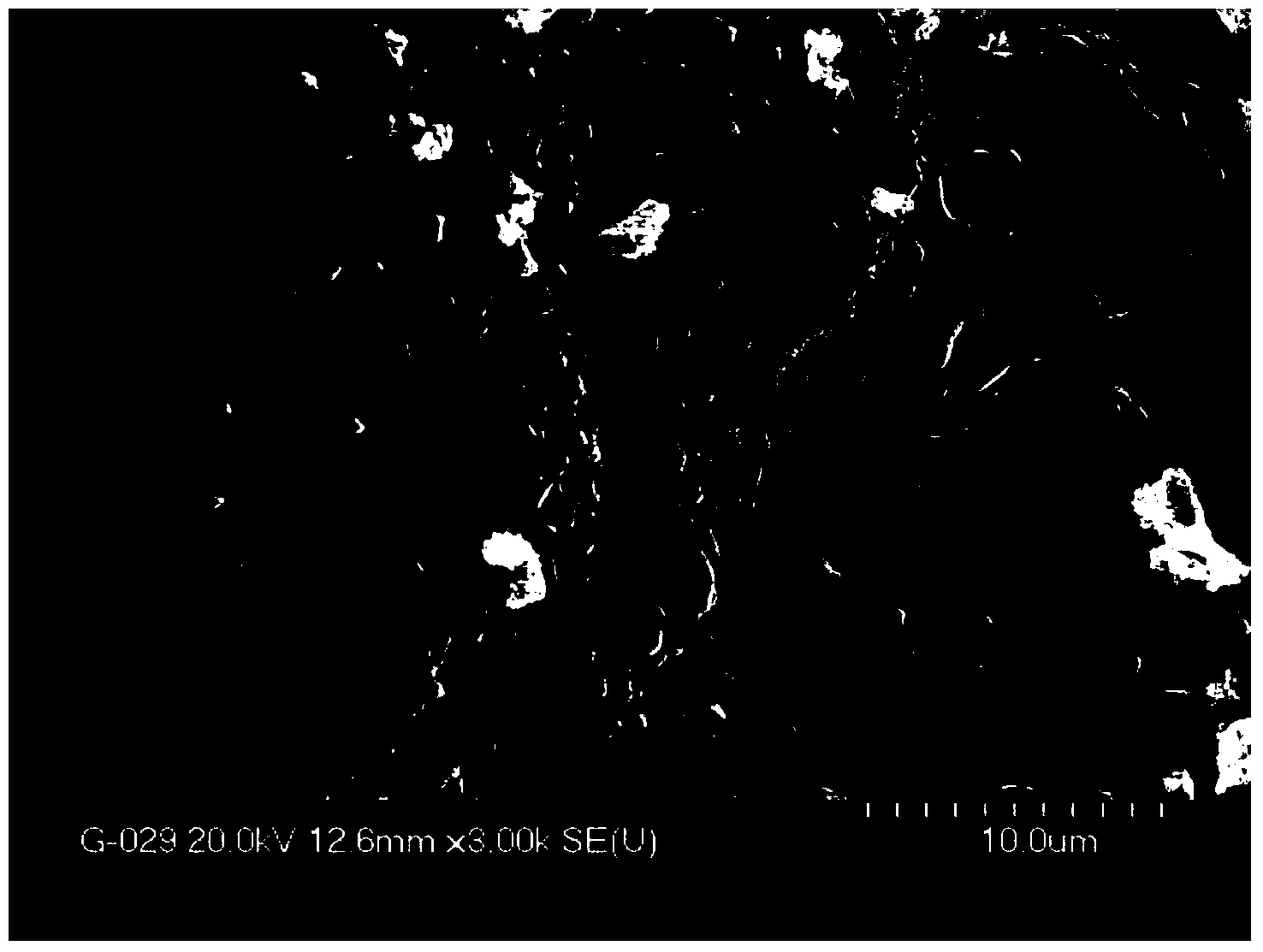

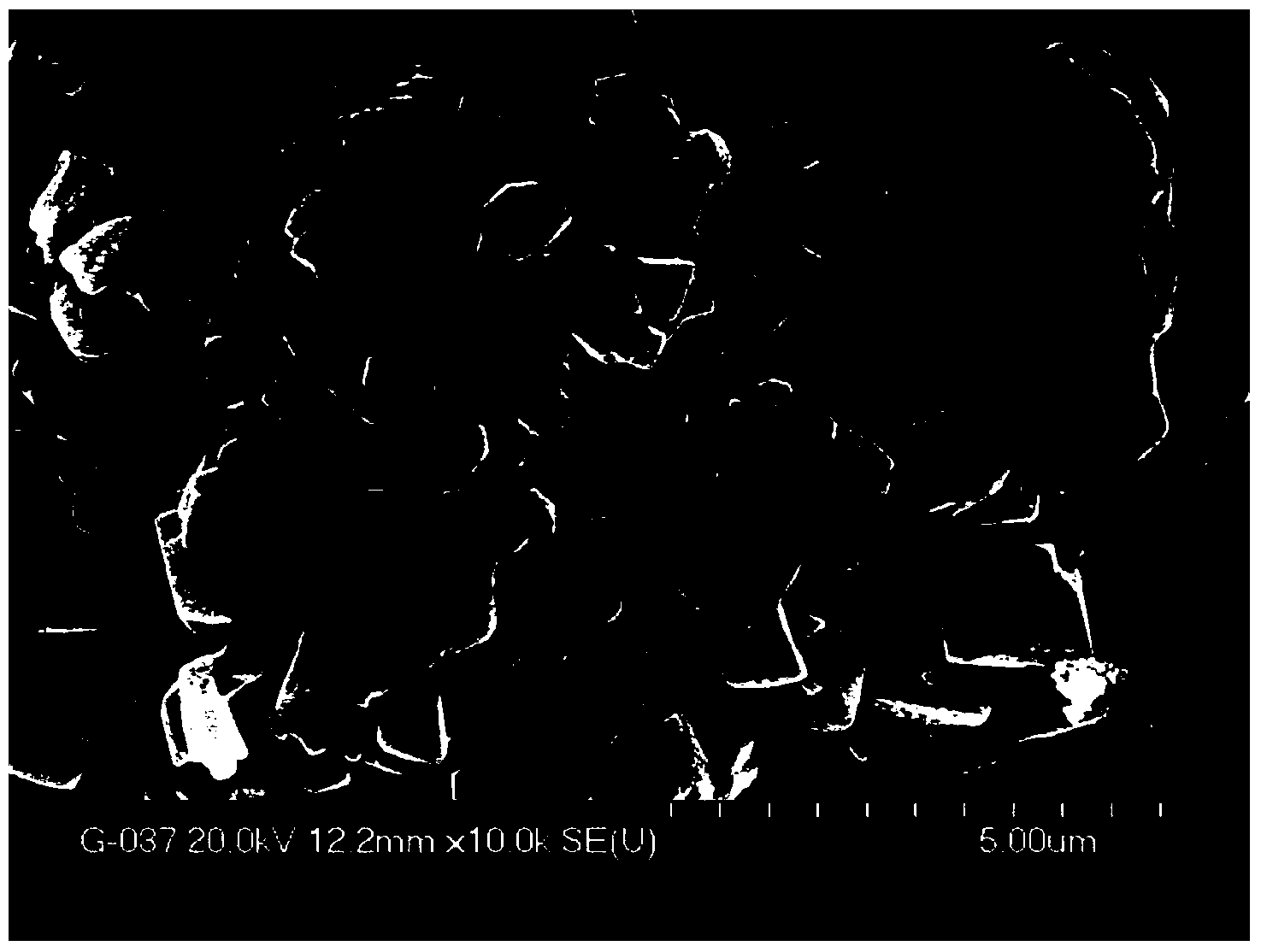

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment 1: A heterogeneous Fenton-like catalyst of the present embodiment is made of reduced iron powder, activated carbon powder, electrolytic copper powder, silicate and starch; wherein electrolytic copper powder accounts for the total 5% to 10% of the total mass, silicate accounts for 2% to 8% of the total mass, 4% to 8% of the total starch, the sum of reduced iron powder and activated carbon powder accounts for 74 to 89% of the total mass, reduced iron The mass ratio of activated carbon powder to activated carbon powder is (1.5-5):1.

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the particle size of the reduced iron powder is 180-220 mesh. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the particle size of the electrolytic copper powder is 180-220 mesh. Others are the same as those in Embodiment 1 or 2.

[0020] Embodiment 3: This embodiment differs from Embodiments 1 to 3 in that the silicate is a pore-forming agent, and the silicate is sodium metasilicate nonahydrate or sodium metasilicate pentahydrate. Others are the same as one of the specific embodiments 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com