Zinc ferrite-tin oxide composite material and preparation thereof and application of zinc ferrite-tin oxide composite material in photocatalysis

A technology of tin oxide and zinc ferrite, which is applied in the field of synthesis of composite photocatalytic materials, can solve the problems of poor photocatalytic activity and photocatalytic stability, unfavorable large-scale production and application, inconvenient recycling and reuse, etc., to solve the problem of difficult recycling , efficient recovery and repeated recycling, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

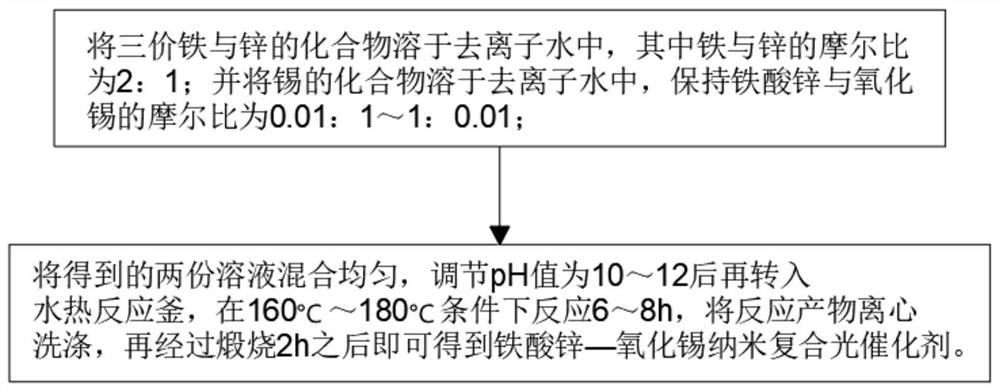

[0026] refer to figure 1 ,, the preparation method of zinc ferrite-tin oxide nanocomposite photocatalyst, comprises the following steps:

[0027] 0.02mol ferric nitrate nonahydrate, 0.01mol zinc nitrate hexahydrate and 0.02mol tin tetrachloride pentahydrate are dissolved in deionized water, wherein the mol ratio of ferric nitrate nonahydrate, zinc nitrate hexahydrate and tin tetrachloride pentahydrate is 2:1:2, keep the molar ratio of zinc ferrite and tin oxide at 0.5:1, stir magnetically until all the compounds are evenly dispersed, then adjust the pH value of the mixed solution to 10 with 2mol / L sodium hydroxide solution, at room temperature Under the conditions, the mixed solution was placed in a hydrothermal reaction kettle, and hydrothermally reacted at 160°C for 6h. After the reaction, the product was centrifuged and washed, and finally calcined at 600°C for 2h to obtain a zinc ferrite-tin oxide nanocomposite photocatalyst.

Embodiment example 2

[0029] The preparation method of zinc ferrite-tin oxide nanocomposite photocatalyst comprises the following steps:

[0030] 0.02mol ferric nitrate nonahydrate, 0.01mol zinc nitrate hexahydrate and 0.01mol tin tetrachloride pentahydrate are dissolved in deionized water, wherein the mol ratio of ferric nitrate nonahydrate, zinc nitrate hexahydrate and tin tetrachloride pentahydrate is 2:1:1, keep the molar ratio of zinc ferrite and tin oxide at 1:1, stir magnetically until all the compounds are evenly dispersed, then adjust the pH of the mixed solution to 11 with 3mol / L sodium hydroxide solution, at room temperature The mixed solution was placed in a hydrothermal reaction kettle under certain conditions, and hydrothermally reacted at 180° C. for 7 hours. After the reaction, the product was centrifuged and washed, and finally calcined at 600° C. for 2 hours to obtain a zinc ferrite-tin oxide nanocomposite photocatalyst.

Embodiment example 3

[0032] The preparation method of zinc ferrite-tin oxide nanocomposite photocatalyst comprises the following steps:

[0033] 0.04mol ferric nitrate nonahydrate, 0.02mol zinc nitrate hexahydrate and 0.01mol tin tetrachloride pentahydrate are dissolved in deionized water, wherein the mol ratio of ferric nitrate nonahydrate, zinc nitrate hexahydrate and tin tetrachloride pentahydrate is 4:2:1, keep the molar ratio of zinc ferrite and tin oxide at 1:0.5, stir magnetically until all the compounds are evenly dispersed, then adjust the pH of the mixed solution to 12 with 4mol / L sodium hydroxide solution, at room temperature The mixed solution was placed in a hydrothermal reaction kettle under certain conditions, and hydrothermally reacted at 200°C for 8 hours. After the reaction, the product was washed by centrifugation, and finally calcined at 600°C for 2 hours to obtain a zinc ferrite-tin oxide nanocomposite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com