Starch-based porous hydrogel and preparation method thereof

A hydrogel and starch-based technology is applied in the field of porous hydrogel composed of starch and its preparation, which can solve the problems of three-dimensional structure damage, shrinkage of pore structure, poor porosity, etc., and achieves the maintenance of three-dimensional structure, structural stability, easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the starch-based porous hydrogel is as follows: adding an initiator, a monomer and a crosslinking agent into the starch solution, and mixing evenly after each component is added, heating to make it fully react, and then obtaining Starch-based hydrogel: after the obtained starch-based hydrogel is washed and swollen, immersed in an organic solvent-water mixed solution for gradient solvent exchange, and dried, the starch-based porous hydrogel can be obtained.

[0023] The starch in the starch solution is soluble starch, cornstarch, carboxymethyl starch, hydroxyethyl starch; the starch solution is: the aqueous solution of starch or the dimethyl sulfoxide solution of starch; the initiator is: Potassium persulfate, ammonium persulfate, azobisisobutyronitrile; the monomer is: at least one of acrylamide, acrylic acid, acrylate and methacrylic acid; the crosslinking agent is: polydimethyl At least one of ethylene glycol acrylate, N,N-methylenebisacrylam...

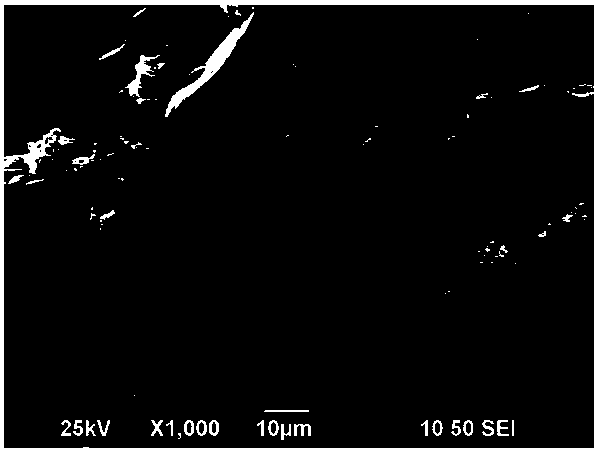

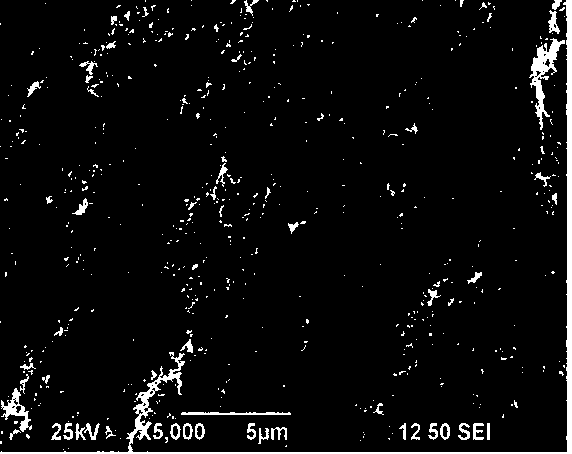

Embodiment 1

[0030]Add 2.00g of starch and 40mL of distilled water into a round bottom flask, stir well, heat to 85°C to fully gelatinize the starch, and then cool to room temperature. Add 4.00 g of monomer acrylamide, 0.08 g of potassium persulfate, and 1.00 g of cross-linking agent polyethylene glycol dimethacrylate to the starch solution in sequence, and heat for 2.5 h to obtain starch-based hydrogel. The hydrogel is taken out, repeatedly soaked in distilled water, swelled, and washed several times to obtain a pure hydrogel. The swollen hydrogel was sequentially immersed in ethanol-water mixed solutions with volume concentrations of 20%, 40%, 50%, 60%, 65%, 70%, 75%, 80%, and 100%. Shake for 2 hours. Oscillate in 100% ethanol for more than 12 hours, take the hydrogel hardened and no longer elastic as the standard, and then dry it in a drying oven to obtain a starch-based porous hydrogel, such as figure 1 The electron micrograph of the cross-section of the starch-acrylamide porous hyd...

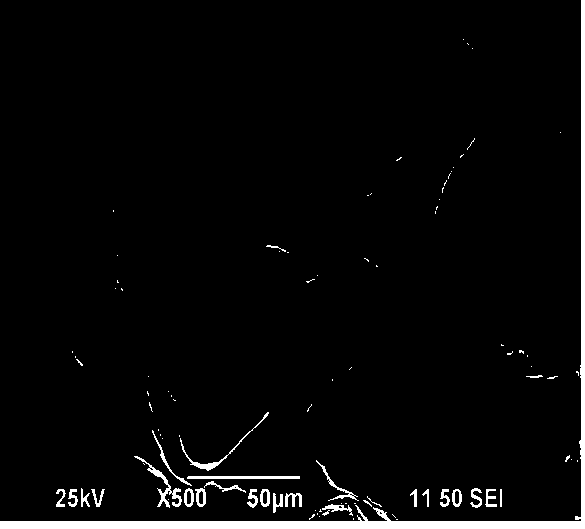

Embodiment 2

[0032] Add 2.00g of starch and 40mL of distilled water into a round bottom flask, stir well, heat to 85°C to fully gelatinize the starch, and then cool to room temperature. 4.00 g of monomer acrylamide and 0.08 g of potassium persulfate were sequentially added to the starch solution, and the temperature was kept at 75°C for 1 hour. Add dilute hydrochloric acid to adjust the pH value of the solution to 1, add 4.00 g of glutaraldehyde as a cross-linking agent, and heat to 50°C for a certain period of time to obtain a starch-based hydrogel. The hydrogel is taken out, repeatedly soaked in distilled water, swelled, and washed several times to obtain a pure hydrogel. The swollen hydrogel was sequentially immersed in ethanol-water mixed solutions with volume concentrations of 20%, 40%, 50%, 60%, 65%, 70%, 75%, 80%, and 100%. Shake for 2 hours. Oscillate in 100% ethanol for more than 12 hours, take the hydrogel hardened and no longer elastic as the standard, and then dry it in a dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com