A kind of single ion polymer electrolyte system and its preparation method and application

A polymer, single-ion technology, used in non-aqueous electrolytes, solid electrolytes, electrolyte immobilization/gelation, etc., can solve problems such as hindering lithium ion migration, reducing battery cycle performance, concentration polarization, etc. The effect of metal ion migration number, inhibition of metal dendrite growth, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

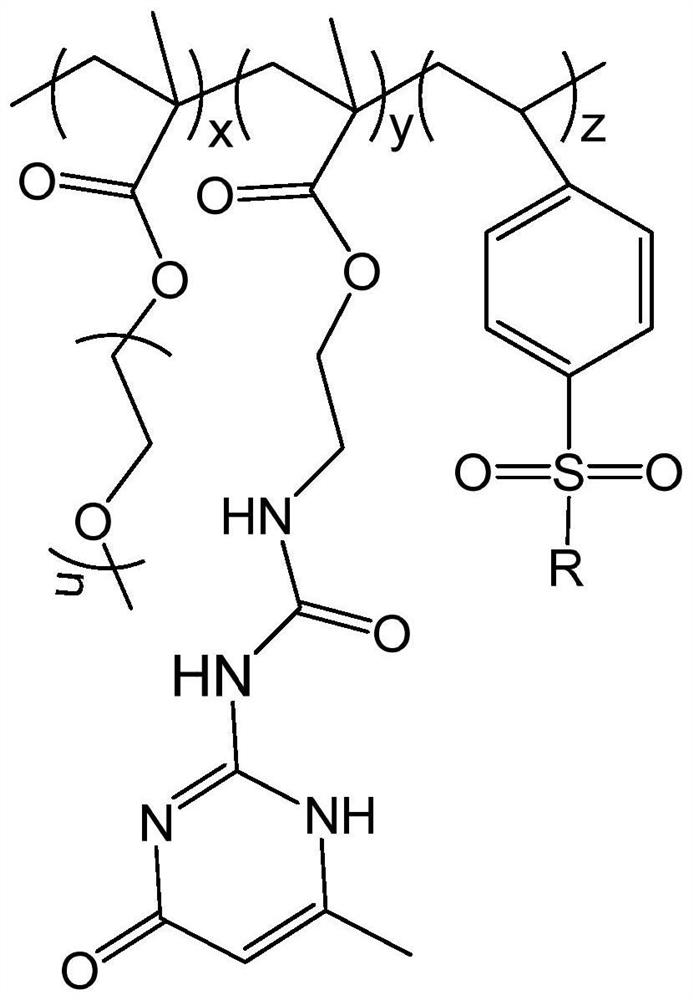

[0078] According to a preferred embodiment of the present invention, the chemical structural formula of the single ion conductor lithium salt containing p-styrenesulfonyl group is:

[0079]

[0080] According to another preferred embodiment of the present invention, the chemical structural formula of the UPyMA containing quadruple hydrogen bonds is:

[0081]

[0082] The chemical structural formula of described polyethylene glycol monomethyl ether methacrylate is:

[0083]

[0084] According to another preferred embodiment of the present invention, in the above-mentioned single-ion polymer electrolyte system, the molar ratio of the lithium salt to the ethoxy structural unit in the single-ion polymer electrolyte is preferably set to 1:5-1 :50. In addition, the relative molecular mass of the polyethylene glycol monomethyl ether methacrylate is preferably set at 200-1000.

[0085] The second aspect of the present invention is to provide a preparation method of a single...

Embodiment 1

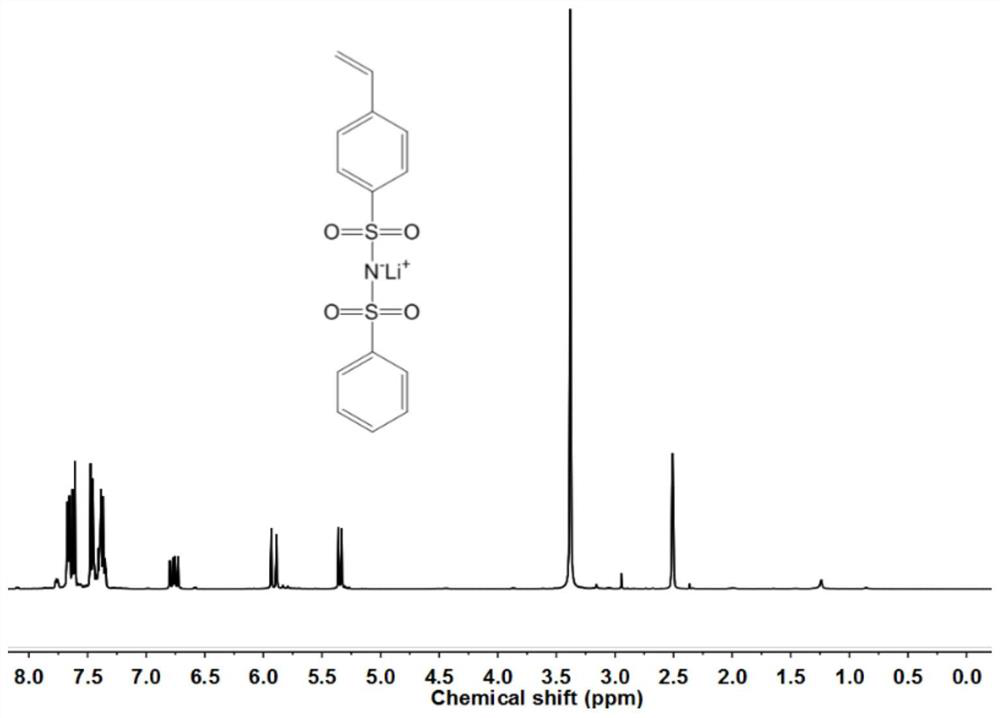

[0152] Add 60mL of N,N-dimethylformamide into a 250mL two-necked round-bottomed flask, stir at 0°C for more than 30 minutes, then drop 50mL of thionyl chloride into N,N-dimethylformamide through a constant pressure dropping funnel in the amide solution. Under 0°C and argon atmosphere, with mechanical stirring, slowly add 0.1 mol p-styrene sodium sulfonate solid powder into the above solution. After the sodium p-styrene sulfonate was completely dissolved, it was stirred for 2 hours at 0°C under an argon atmosphere, and then stirred for another 6 hours at room temperature under an argon atmosphere, and the resulting reaction solution was placed in a refrigerator at 4°C overnight. The reaction solution was dissolved in deionized water, extracted with dichloromethane, anhydrous MgSO 4 Drying, suction filtration, rotary evaporation, and drying gave p-styrenesulfonyl chloride, which was dissolved in anhydrous acetonitrile for later use.

[0153] Dissolve 0.1mol benzenesulfonamide,...

Embodiment 2

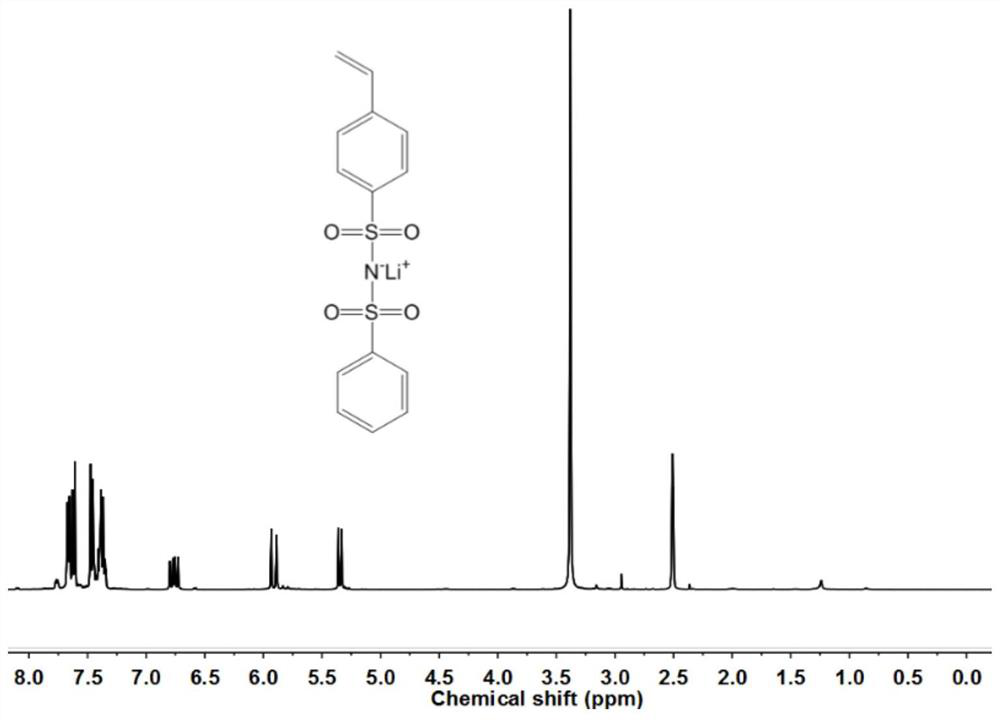

[0158] Add 60 mL of tetrahydrofuran into a 250 mL two-necked round-bottom flask, stir at 0°C for 30 minutes, and then drop 50 mL of thionyl chloride into the tetrahydrofuran solution through a constant pressure dropping funnel. Under 0°C and argon atmosphere, with mechanical stirring, slowly add 0.1 mol p-styrene sodium sulfonate solid powder into the above solution. After the sodium p-styrenesulfonate was completely dissolved, the mixture was stirred at 0° C. under an argon atmosphere for 1 hour, and then stirred at room temperature under an argon atmosphere for another 30 minutes to obtain a reaction solution. The reaction solution was dissolved in deionized water, extracted with dichloromethane, anhydrous MgSO 4 Drying, suction filtration, rotary evaporation, and drying gave p-styrenesulfonyl chloride, which was dissolved in anhydrous acetonitrile for later use.

[0159] Dissolve 0.1 mol of trifluoromethanesulfonamide, 0.2 mol of 4-dimethylaminopyridine and 0.3 mol of trie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com