Novel suspension type silage round bale film wrapping machine

A hanging and film-wrapping technology, which is applied in the direction of object rotation wrapping and packaging, can solve the problems of bale density, weight difference, excessive human participation, and easy sliding of bale, etc., and achieves high stretch film rate and good wrapping Good sealing performance and high working quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described further according to accompanying drawing:

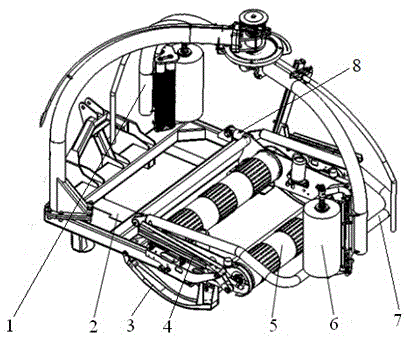

[0019] Such as figure 1 As shown, the film wrapping machine of the present invention includes a chassis mechanism 2, on which a rotating part 1, a ground support frame 3, a film cutting part 4, a roller frame hydraulic cylinder 8, a U-shaped pick-up rod 7 and a support are installed on the chassis mechanism 2. Roller mechanism 5.

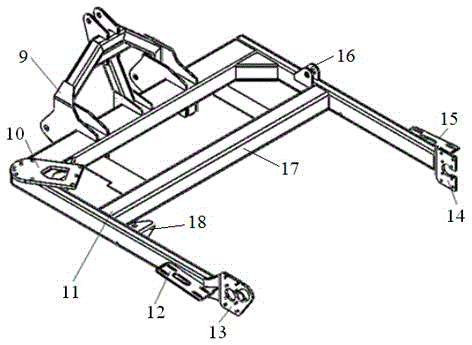

[0020] Such as figure 2 As shown, the chassis mechanism 2 in the film wrapping machine of the present invention comprises a U-shaped chassis support 11 arranged horizontally, a crossbeam 17 is provided between the two side walls of the chassis support 11, and a suspension frame mechanism is provided on the bottom edge of the chassis support 11 9. A film-wrapping frame seat plate 10 is provided at the connection between the bottom edge of the chassis support 11 and a side wall, and the end of the side wall far away from the bottom edge of the chassis support 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com