Rotary mud blowout preventer for well mouth

A blowout preventer and rotary technology, which is used in flushing wellbore, wellbore/well components, earth-moving drilling, etc., can solve the problems of large mud residue, large floor space, and unclean recovery, and achieves compact structure, Small footprint and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

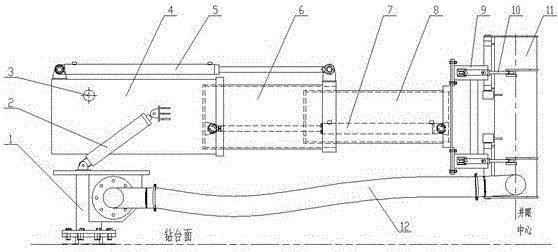

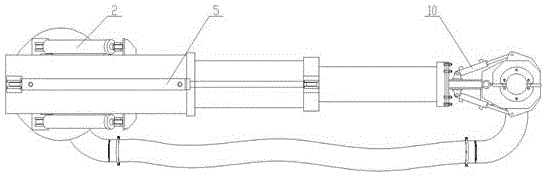

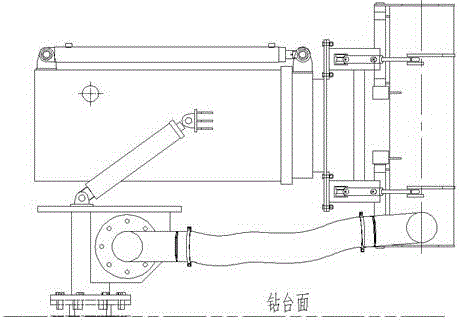

[0022] Such as Figure 1 to Figure 4 Shown 1. A wellhead rotary mud blowout preventer, which includes: a base assembly 1 fixed on the drill floor, a first telescopic arm 4 that is nested with each other, a second telescopic arm 6, a third Section telescopic arm 8, a rotary hydraulic cylinder 2 is installed between the base assembly 1 and the first section telescopic arm 4, the first section telescopic arm 4 is hinged on the telescopic arm support through the rotating shaft 3, the third section telescopic arm 8 The top end is connected to one end of the opening and closing column 9 by bolts, and the other end of the opening and closing column 9 is connected to the mud cylinder 11. The mud cylinder 11 includes a symmetrical left cylinder wall and a right cylinder wall connected to each other. The mud cylinder Opening and closing hydraulic cylinders 10 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com