Hot pressing forming mould and hot pressing forming method of super long branch pipe three-way pipe fitting

A technology for hot-press forming and tee fittings, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

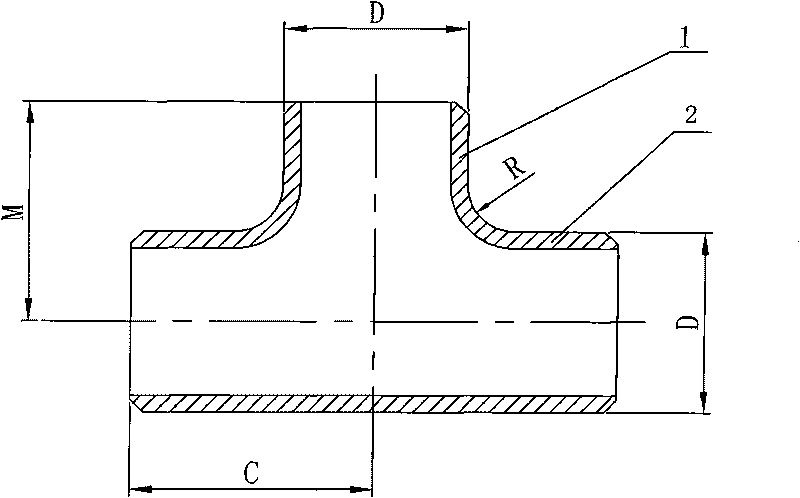

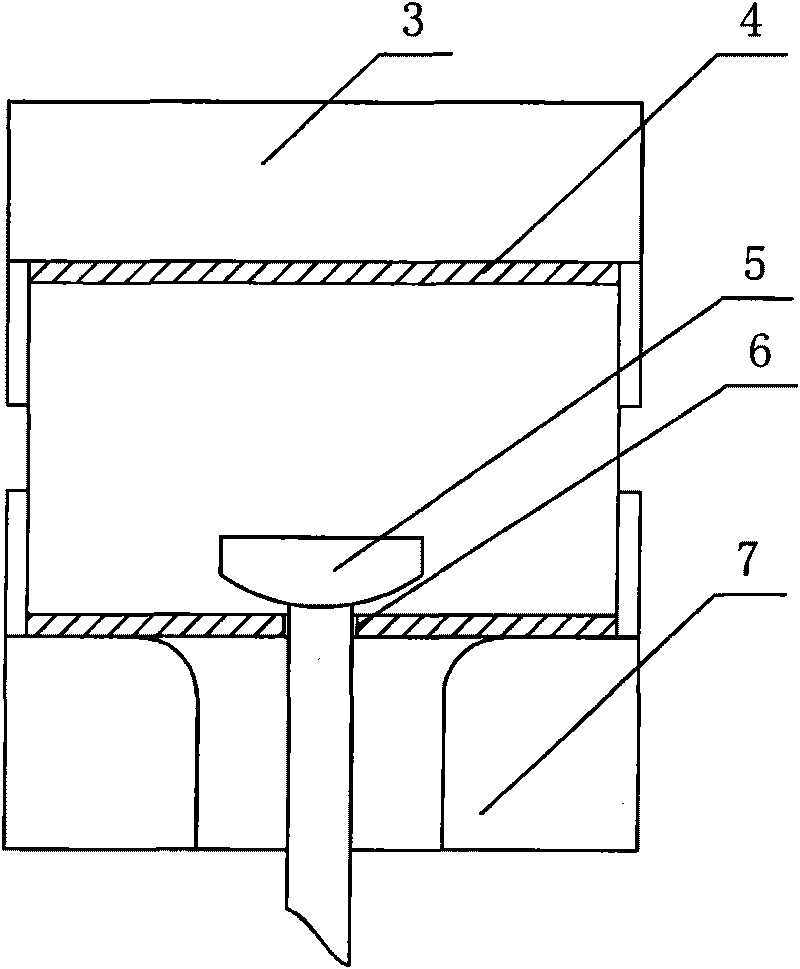

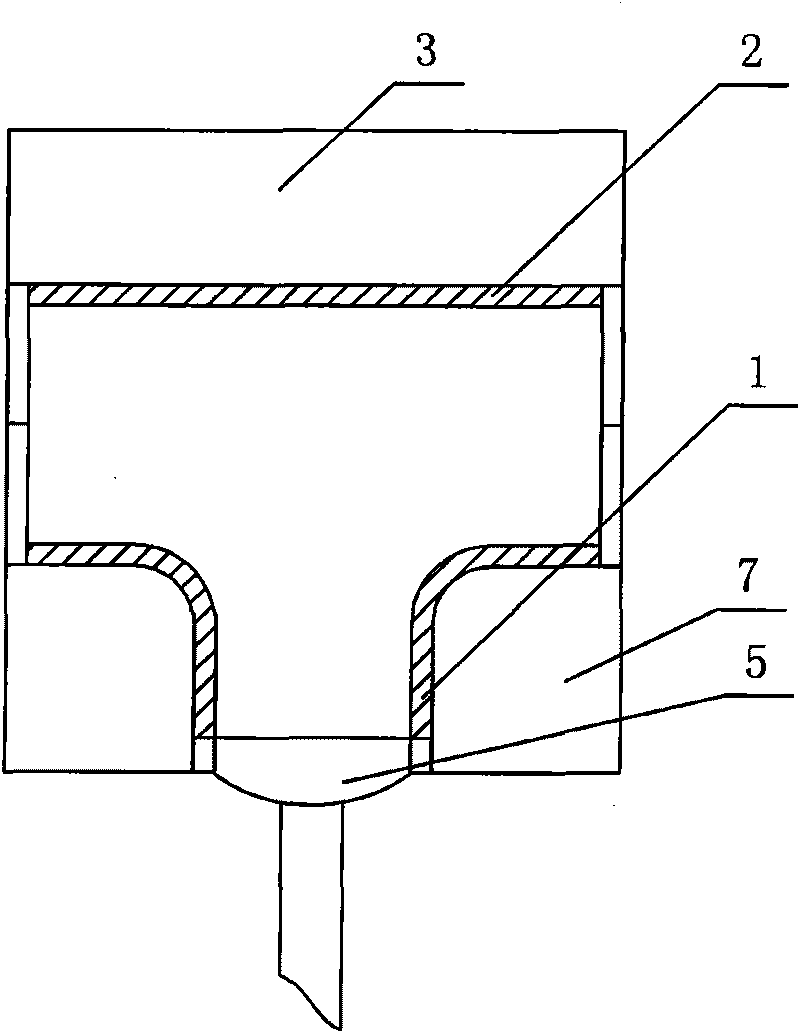

[0039] Such as Figure 4 to Figure 16 As shown, the hot press forming mold of the ultra-long branch pipe tee fitting of the present invention comprises a first upper die 11, a second upper die 19, a first lower die 13, a second lower die 15, a third lower die 17, The fourth lower mold 20 and the tie rod 22. Such as Figure 4 , Figure 5 , Image 6 As shown, the primary forming mold is composed of the first upper die 11 and the first lower die 13: the diameter of the straight pipe section die cavity of the first upper die 11 is D1; the straight pipe die cavity diameter of the first lower die 13 is D1, and the branch pipe section The diameter of the mold cavity is D1, and the radius of the fillet at the transition between the straight pipe and the branch pipe is R1. Such as Figure 7 , Figure 8 , Figure 9 As shown, the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com