High-barrier-property biodegradable mulching film and preparation method thereof

A technology of degradable mulch film and high barrier property, applied in the field of film materials, can solve the problems of poor barrier performance, easy breakage, poor mechanical properties of degradable mulch film, etc., and achieves the effect of good barrier performance, not easy to be damaged, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

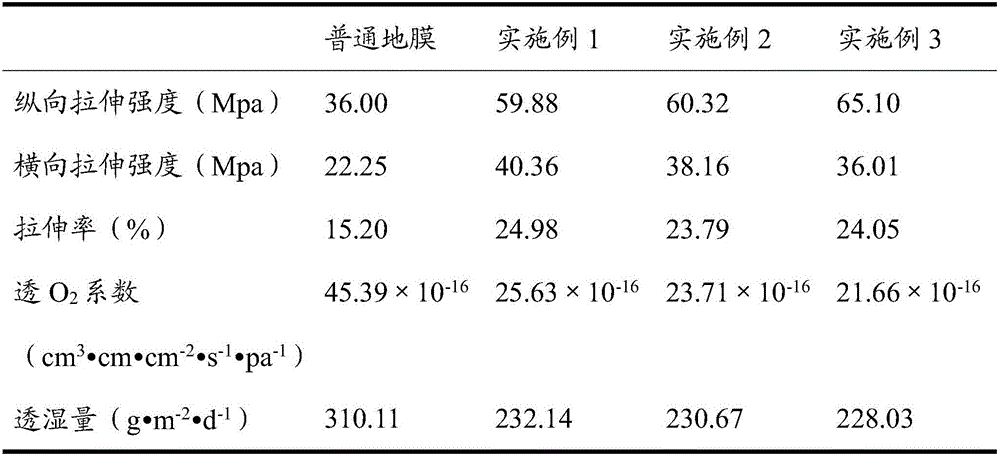

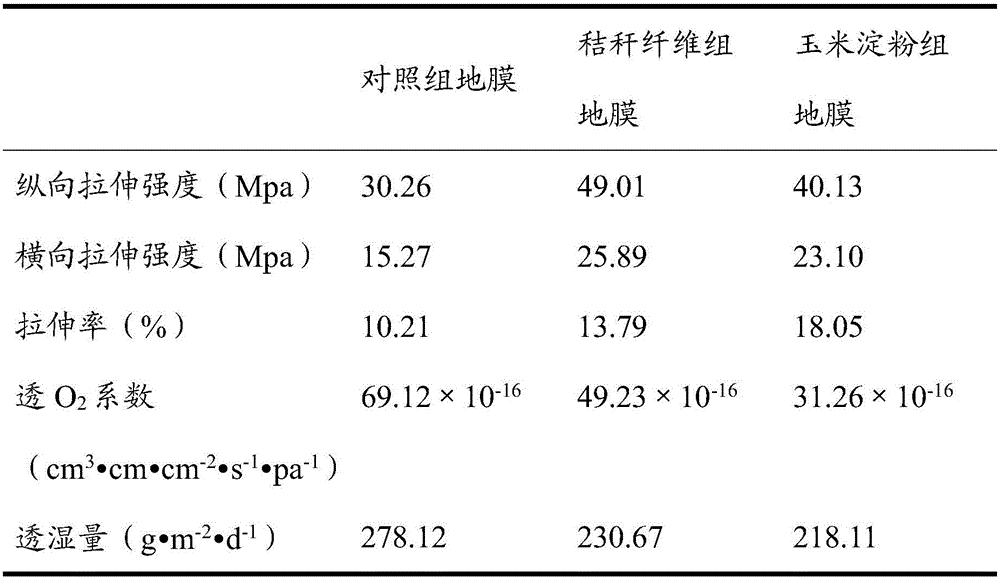

Examples

Embodiment 1

[0030] A high-barrier biodegradable mulch film in Example 1 is made of the following components by weight: 10 parts of wheat straw fiber, 30 parts of corn starch, 4 parts of sodium hydroxide, 1 part of polyvinyl alcohol, carboxyl 2 parts of methylcellulose, 4 parts of glyoxal, 10 parts of glycerin, 0.8 parts of cellulase, 1.5 parts of calcium stearate, 95 parts of deionized water; the wheat straw fibers are washed and dried Prepared by acid hydrolysis, specifically prepared according to the following steps:

[0031] Step 1, prepare masterbatch

[0032] Step 1.1, preparing wheat straw fiber

[0033] Washing the wheat stalks and drying them at 40°C to obtain dry stalks;

[0034] Mix 1mol / L hydrochloric acid and 5g / L citric acid evenly according to the volume ratio of 1:1 to obtain the acid solution;

[0035] Mix the dry straw and the acid solution according to the ratio of 1kg:5L evenly, stir for 20min, filter, collect the filter residue and dry it at 40°C to obtain wheat str...

Embodiment 2

[0043] A high-barrier biodegradable mulch film in Example 1 is made of the following components by weight: 9 parts of wheat straw fiber, 25 parts of corn starch, 3 parts of sodium hydroxide, 1.5 parts of polyvinyl alcohol, carboxylate 1.5 parts of methyl cellulose, 5 parts of glyoxal, 8 parts of glycerin, 1 part of cellulase, 1 part of sodium stearate, 90 parts of deionized water; the wheat straw fibers are washed and dried Prepared by acid hydrolysis, specifically prepared according to the following steps:

[0044] Step 1, prepare masterbatch

[0045] Step 1.1, preparing wheat straw fiber

[0046] Washing the wheat stalks and drying them at 45°C to obtain dry stalks;

[0047] Mix 1mol / L hydrochloric acid and 5g / L citric acid evenly according to the volume ratio of 1:1 to obtain the acid solution;

[0048] Mix the dry straw and the acid hydrolysis solution evenly in the ratio of 1kg:5L, stir for 30min, filter, collect the filter residue and dry it at 45°C to obtain wheat st...

Embodiment 3

[0056] A high-barrier biodegradable mulch film in Example 1 is made of the following components by weight: 12 parts of wheat straw fiber, 35 parts of corn starch, 4 parts of sodium hydroxide, 2 parts of polyvinyl alcohol, carboxylate 1 part of methylcellulose, 3 parts of glyoxal, 5 parts of glycerin, 0.5 part of cellulase, 1.5 parts of epoxidized soybean oil, 100 parts of deionized water; the wheat straw fibers are cleaned and dried Prepared by acid hydrolysis, specifically prepared according to the following steps:

[0057] Step 1, prepare masterbatch

[0058] Step 1.1, preparing wheat straw fiber

[0059] Washing the wheat stalks and drying them at 42°C to obtain dry stalks;

[0060] Mix 1mol / L hydrochloric acid and 5g / L citric acid evenly according to the volume ratio of 1:1 to obtain the acid solution;

[0061] Mix the dried straw and the acid solution according to the ratio of 1kg:5L evenly, stir for 25min, filter, collect the filter residue and dry it at 42°C to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com