Aluminium hydroxide flame retardant adhesive and preparation method thereof

A technology of aluminum hydroxide and flame retardant glue, applied in the field of flame retardant materials, can solve the problems of high manufacturing cost and high production process requirements, achieve high Green strength, improve wear resistance, and avoid the effects of soot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The purpose of the present invention is achieved through the following technical solutions.

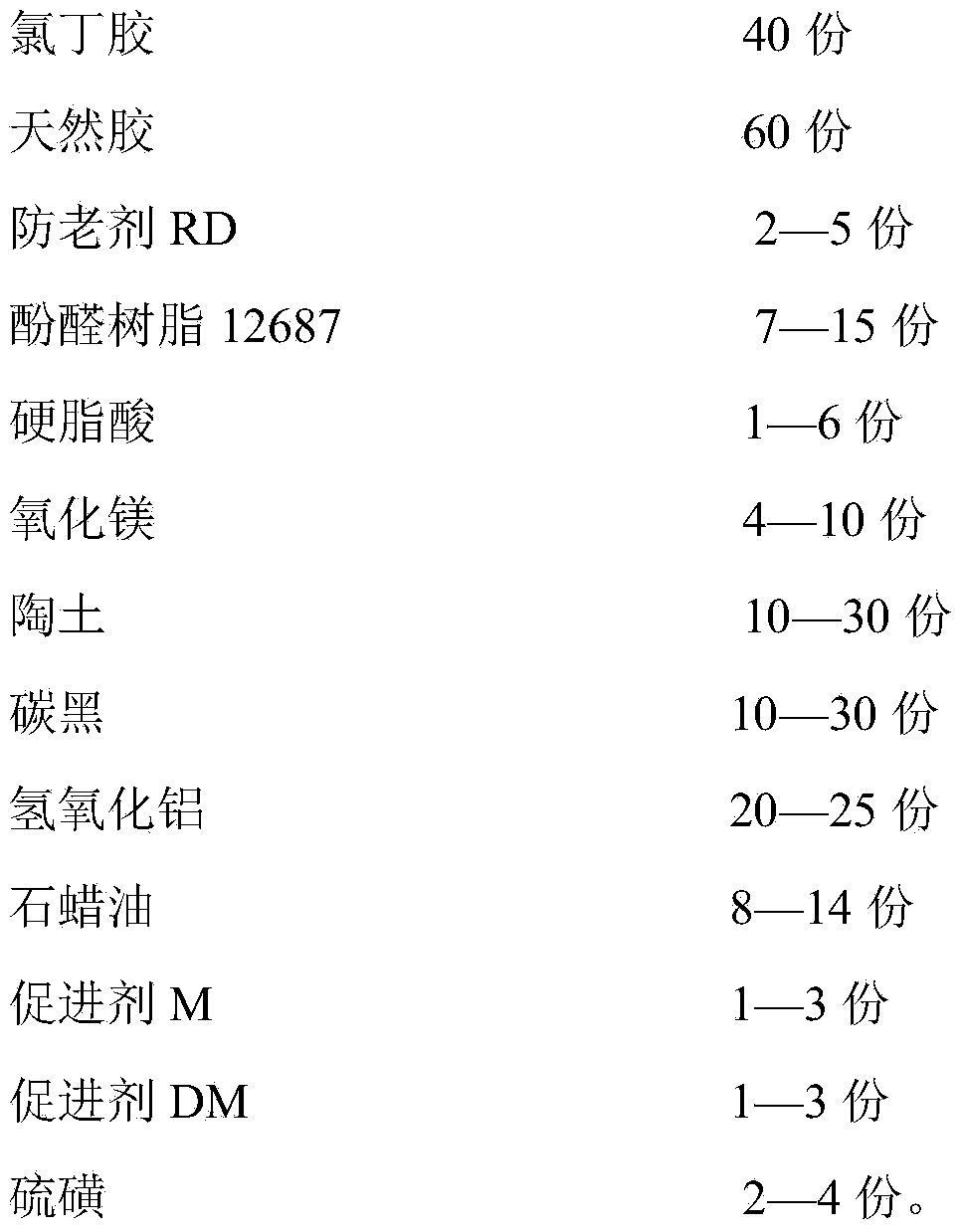

[0042] The preparation method is as follows, and the components are as follows in parts by mass:

[0043]

[0044] The neoprene is neoprene CR322, using the CR322 model produced by Chongqing Changshou Chemical Co., Ltd. The oxygen index of neoprene is 50%. Generally, the oxygen index is more than 27%, which is a self-extinguishing material, which can improve the flame retardancy. The oxygen index of this type of neoprene CR322 is higher than that of general materials, and it has strong self-extinguishing performance.

[0045] Carbon black is made of N220, N330, N550, N774, and N990, and the mass parts are 1:2:2:1:4. Among them, carbon black N220 and carbon black N330 can greatly improve the rubber strength, but a large amount of use will cause Reduce tensile elongation, carbon black N550, carbon black N774, carbon black N990 have slightly poorer reinforcement performance, b...

Embodiment 2

[0063] The purpose of the present invention is achieved through the following technical solutions.

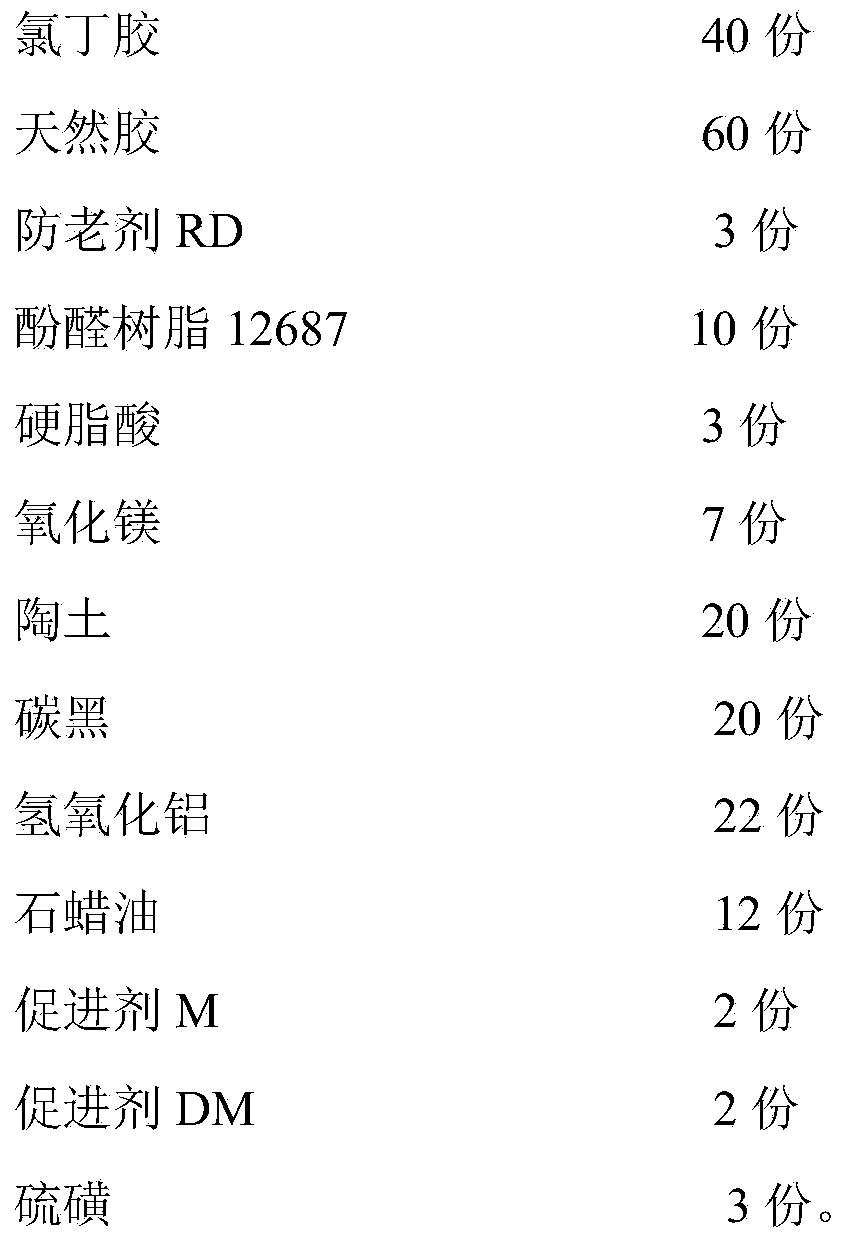

[0064] The preparation method of the present embodiment is the same as that of Example 1, and its difference is that the quality of each material, the components are as follows in parts by mass:

[0065]

[0066]

[0067] The oxygen index of neoprene is 40%. Generally speaking, the oxygen index of more than 27% is a self-extinguishing material, which can improve the flame retardant performance. The oxygen index of neoprene is higher than that of general materials, and it has strong self-extinguishing performance.

[0068] Carbon black is compounded from N220, N330, N550, N774, and N990, and the mass parts are 1:2:2:1:4.

[0069] Choose stearic acid 1803 for stearic acid. The stearic acid 1803 uses animal fat as the main raw material, which greatly improves the degree of activation, greatly improves the vulcanization speed and degree of rubber preparation, and reacts faste...

Embodiment 3

[0073] The purpose of the present invention is achieved through the following technical solutions.

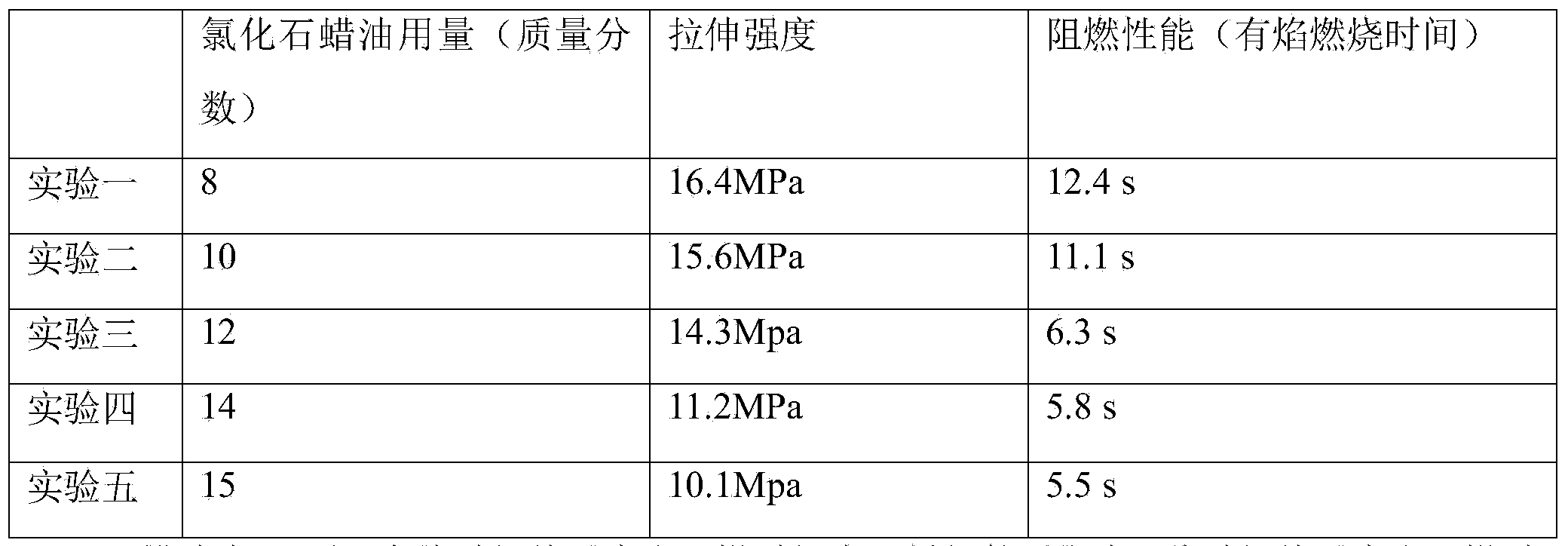

[0074] The preparation method of the present embodiment is the same as that of Example 1, and its difference is that the quality of each material, the components are as follows in parts by mass:

[0075]

[0076]

[0077] The oxygen index of neoprene is 30%, and generally the oxygen index exceeds 27%, which is a self-extinguishing material, which can improve the flame retardant performance. The oxygen index of neoprene is higher than that of general materials, and it has strong self-extinguishing performance.

[0078] Carbon black is compounded from N220, N330, N550, N774, and N990, and the mass parts are 1:2:2:1:4.

[0079] Stearic acid selects stearic acid 1842, and its stearic acid 1842 takes animal fat as the main raw material.

[0080] The mass fraction of aluminum hydroxide is 20 parts, and the synergistic effect is obvious when superfine aluminum hydroxide and hal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com